RDH 100

For production environments: RDH 100 series RFID readers

Robust and can be installed in metallic environments

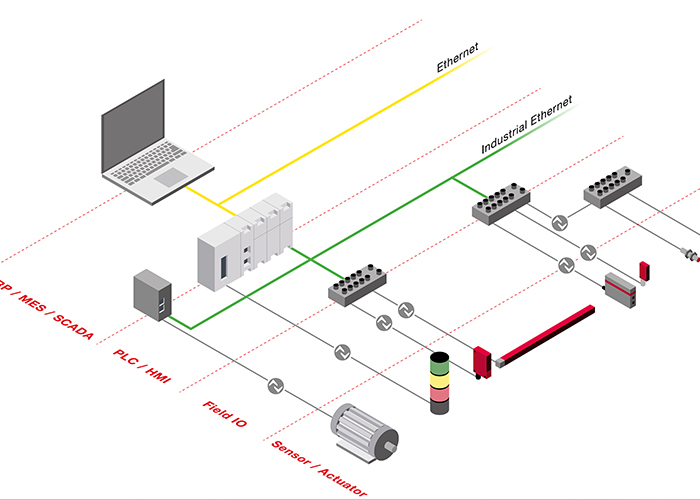

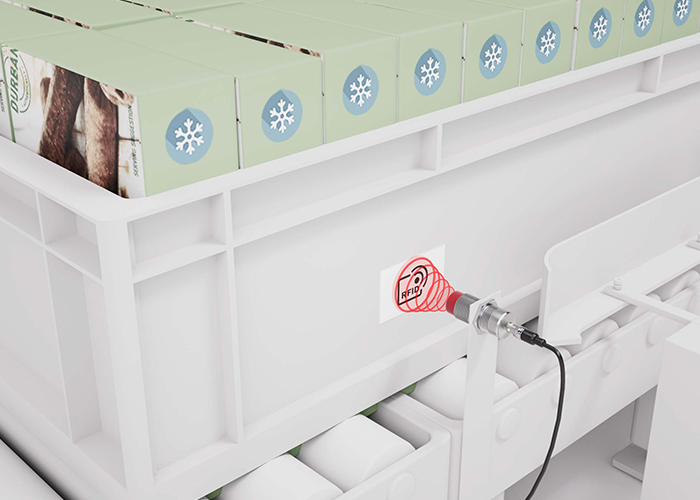

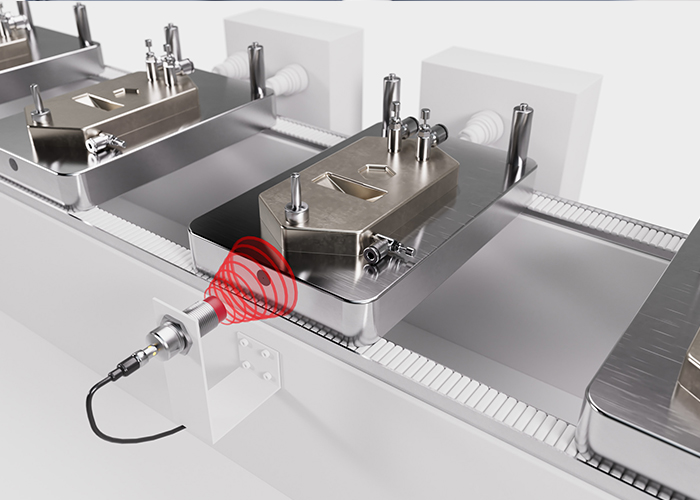

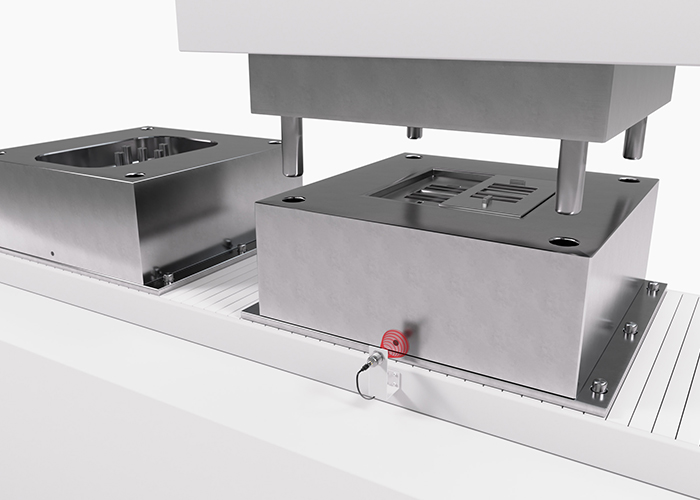

When automating production lines that require robustness and insensitivity to environmental influences, high-performance RFID systems are the preferred identification systems for continuously tracking individual production steps and ensuring quality requirements.

Space requirements are often very limited, especially in the production environment, in production cells and at assembly stations. Thanks to its design, the cylindrical RDH 142 high-frequency reader with a diameter of 30 mm can be mounted very easily and flexibly in metallic environments and delivers reliable identification results with a reading range of up to 60 mm.

The RFID reader is available in the RDH 142 version with IO-Link – for uncomplicated, fast use at the sensor level.