Safe bar code positioning system

FBPS 600i safe bar code positioning system up to PL e

New possibilities thanks to additional PROFIsafe interface

The FBPS 600i safety bar code positioning system only requires one sensor for safe position detection. This greatly simplifies integration and makes the system much easier to set up.

The new device now gives you two flexible interface options:

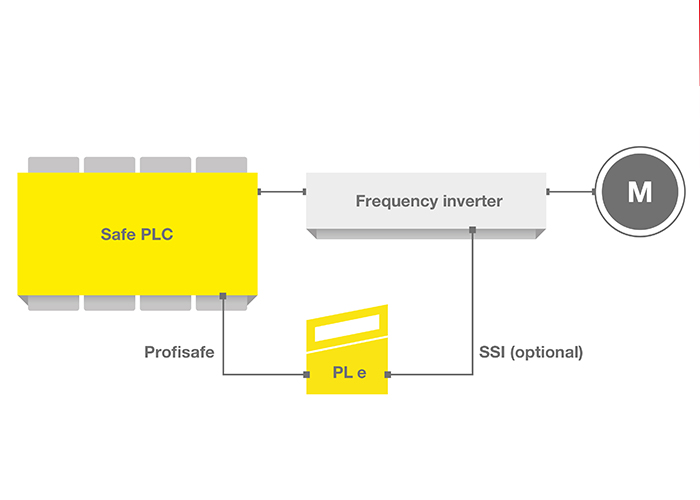

- FBPS 648i: This model is connected to a safe PLC via a PROFIsafe interface. A linear topology can be set up thanks to the integrated switch. It also has a non-safe SSI interface that enables a direct connection to the drive’s frequency inverter (FI). It can be easily parameterized via the hardware manager and the GSDML or FI configuration.

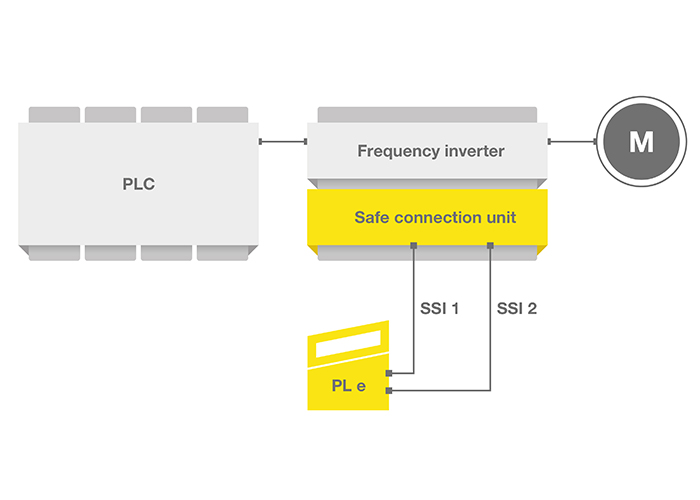

- FBPS 6x7i: This device is connected via two SSI interfaces to a safe evaluation unit, for example a frequency inverter or a safety control.

Both models are suitable for a wide range of applications that require safe positioning with Performance Level e. They make it particularly easy to implement safety functions and significantly reduce installation as well as maintenance costs.

Advantages for you

- Safe positioning with just one device up to Performance Level e (PL e)

- Direct connection to safe frequency inverters or safety controls (F-PLC)

- Compact design with low space requirements and simplified installation

- Particularly straightforward safety function implementation

- Short braking distances and optimized speeds thanks to a fast error response of just

10 ms – ideal for use on fast stacker cranes and electric monorail systems - Reliable operation thanks to simultaneous scanning of multiple codes as well as extremely robust, UV-resistant bar code tape

- Large working range from 50 mm to 170 mm for a wide range of applications with curves

- Sophisticated mounting system for easy installation and seamless integration

The new FBPS 648i model rounds out the portfolio of positioning sensors with PROFIsafe and the combined SSI interface.

Highlights

Simple and safe

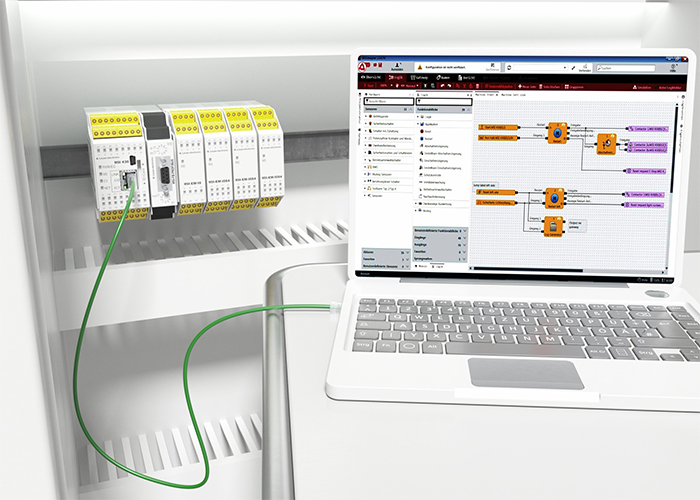

The sensor can be parameterized and integrated effortlessly and reliably – without any additional tools, directly in your familiar work environment. Setup is intuitive and convenient, whether in the F-PLC’s hardware manager or directly via the safety card in the drive's frequency inverter. Thanks to the GSDML or parameter file, the device settings are immediately available in the hardware manager or in the safety card’s device library. This allows for seamless integration and configuration with minimal risk of error, significantly simplifying use and considerably reducing effort. Depending on the requirements, the safe position value can be further processed via the SSI or PROFIsafe interface – flexibly and reliably, entirely in accordance with your concept. Safe speed output is also available as a function with the PROFIsafe model.

Suitable for curved routes (tracks) and precise positions

The particularly robust and resistant BCB bar code tape, which is affixed along the transportation path, means even curved track layouts up to 10,000 meters long can be clearly and reliably detected.

Additional functions, such as speed output, complement automatic transport systems perfectly. They help to reduce wear, shorten braking distances and make efficient use of buffer zones – for a smooth and safe process.

Safe position detection via frequency inverter

The FBPS 600i requires just one sensor for safe position detection. The device is connected to a safe evaluation unit – e.g. a frequency inverter – via two SSI interfaces. In addition, the devices already meet the requirements for PL e/SIL 3. This makes safety functions particularly easy to implement and reduces installation and service costs.

Safety control with direct position sensor connection

The FBPS 648i device is connected to a safe control via a PROFIsafe interface. A linear topology can be set up with the integrated switch. A non-safe SSI interface is also available. In addition to the safe position value, this device also provides a safe speed output.

Suitable for fast movements

The FBPS 600i is ideal for position detection in applications involving fast movements, e.g. on stacker cranes. For this purpose, the FBPS 600i has an extremely short error reaction time of just 10 ms. This allows speed curves and handling performance to be optimized.

Reliable operation

The FBPS 600i operates with exceptional reliability. Each scanning process reads multiple codes, from which the software determines highly accurate position values. The oblique path of the scanning beam and the movement of the device ensure that each code is scanned at different points. This prevents reading errors caused by local contamination or damage.

The bar code tape is also optimized for industrial use. The self-adhesive plastic tape is UV resistant, extremely resilient and mechanically durable. In addition, the printed position values are easy to read and simplify handling.

Always quick and easy to install

The clever fastening concept with quick-change system ensures simple mounting of the FBPS 600i. The devices are securely mounted to the clamp bracket using an easily accessible screw. This saves time during installation and allows the devices to be quickly replaced in the event of servicing. Furthermore, the FBPS 600i is easy to integrate into any system thanks to its large working range of 50 to 170 mm.

Suitable for a wide range of environmental conditions

The wide temperature range enables use in various systems with positioning tasks, even under demanding conditions. A model with integrated optics heating is also available for environments with high humidity and low temperatures. This ensures increased availability and prevents fogging so that the sensor always works reliably.

Application

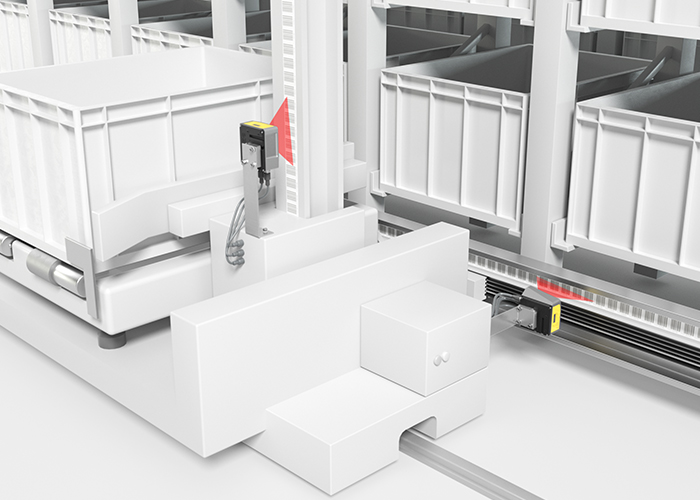

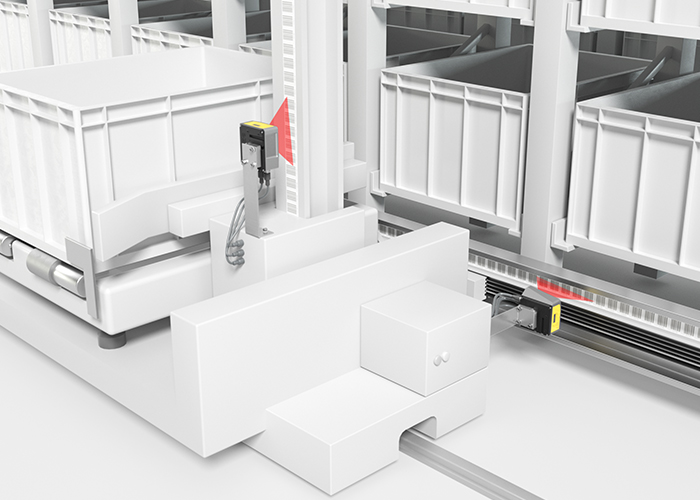

Safe positioning with bar code positioning system

Requirement:

The stacker crane or load receptacle must be positioned in the X-direction (travel axis) and Y-direction (lifting axis) accordingly for the position to be approached. Often the risk assessment requires safe position and speed monitoring. For this purpose, safe position detection is necessary.

Solution:

The FBPS 600i safe bar code positioning system requires just one sensor for safe position detection. The device is connected via two SSI interfaces or a PROFIsafe interface to a safe evaluation unit – e.g. a frequency inverter – or safe PLC and is suitable for applications up to PL e. This makes it easy to implement safety functions.

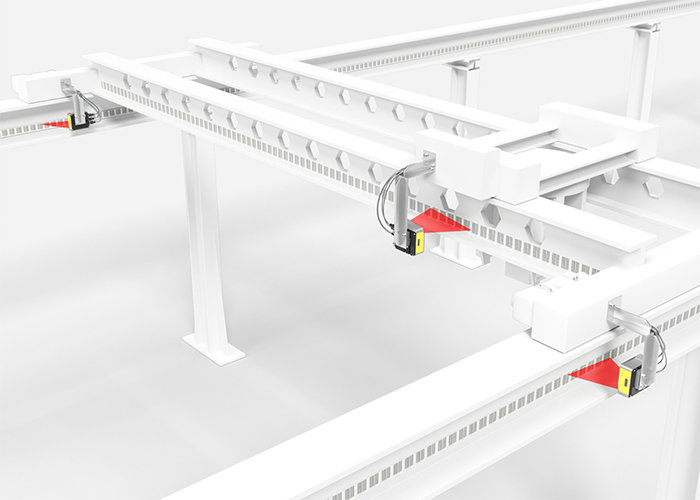

Positioning of the transport unit

Requirement:

For control of the electric monorail system, the position of the transport unit on the carrier must be known with millimeter precision at all times. “Safe positioning” must be ensured especially when workers are working very close to the transport unit.

Solution:

The safe FBPS 600i bar code positioning systems enable precise positioning over a length of up to 10,000 m. The devices can be easily integrated into the control thanks to a wide range of interfaces. The self-adhesive bar code tapes are optimized for industrial application and are extremely resilient.

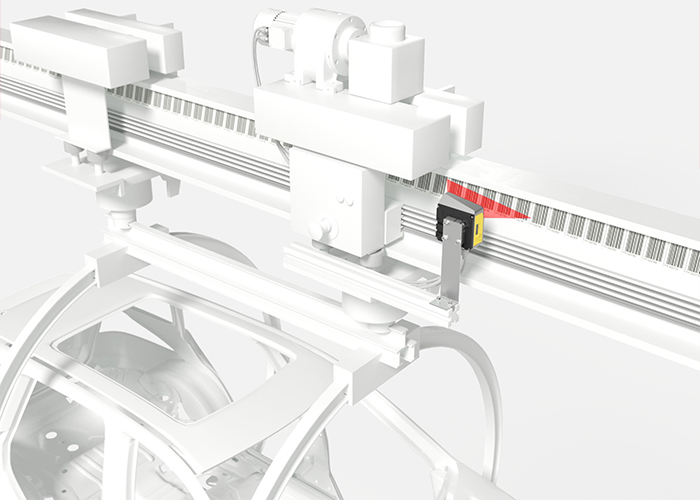

Synchronous trolley positioning

Requirement:

The crane or trolley should be positioned according to the point to be approached. Several cranes can be located on one guide rail.

Solution:

The BPS 300i bar code positioning systems or the safe version FBPS 600i enable exact positioning. The devices can be easily integrated into the control thanks to a wide range of interfaces. The self-adhesive bar code tapes are optimized for industrial application and are extremely resilient.

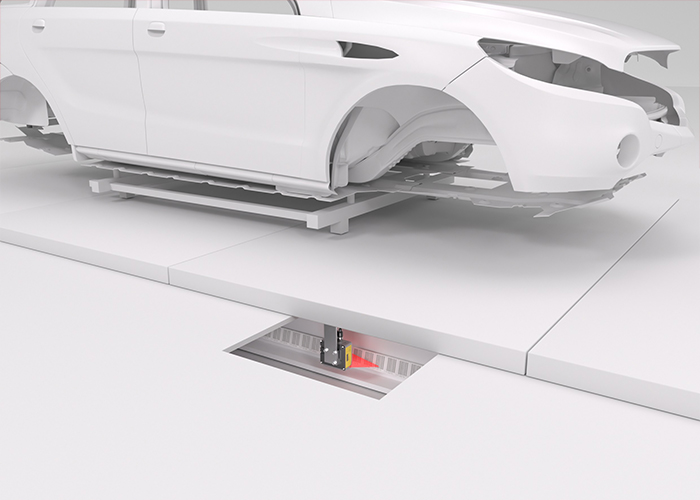

Skillets in assembly

Requirement:

In automatic transport during assembly on large objects, a safe position and speed must always be detected, even in constrained spaces.

Solution:

The safe FBPS offers a flexible mounting position with its cable outlet downwards/to the side and a minimum working range of 50 mm. The integrated PROFINET/PROFIsafe interface enables direct integration into the safe control.

Technical features

| Safety | Safety PL e, SIL 3, category 4 (EN ISO 13849-1 and IEC 61508) |

|

| Error response time | 10 ms … 400 ms (adjustable) | |

| Connection | 2x SSI interface: 2x M12 connector PROFINET/ PROFIsafe, opt. SSI: 2(3)x M12 connector Power supply: M12 connector Configuration and diagnosis: Mini USB |

|

| Reproducibility | +/- 0.15 mm (1 sigma) | |

| Reading distance | 50 ... 170 mm | |

| Protection class | IP 65 | |

| Temperature range | -5 ... +60°C With heating: -35…+60°C |

|

| Dimensions, W x H x D | Connections on the side: 116.3 x 112.5 x 51.5 mm Bottom connections: 105 x 123.8 x 51.5 mm |

|

| Display (optional) | Display of position and status information | |

| Status signal of reading quality | For early detection of soiling |

| Features | Extremely robust plastic tape, UV- resistant, self-adhesive with acrylic adhesive, position values printed in plain text |

|

| Standard bar code tapes | Height: 25 mm, 47 mm Length: up to 200 m |

|

| Configurable bar code tapes | Height: 20 mm to 140 mm Selectable start and end value ranging from 0 to 10,000 m Twin tape |

|

| Bar code grid dimension | 30 mm / 40 mm |

Downloads

Article list

- Interface: 2-channel SSI with CRC

- Interface: 2-channel SSI with CRC

- Interface: 2-channel SSI with CRC

- Interface: 2-channel SSI with CRC

- Interface: 2-channel SSI with CRC

- Interface: 2-channel SSI with CRC

- Interface: 2-channel standard SSI

- Interface: 2-channel standard SSI

- Interface: 2-channel standard SSI

- Interface: 2-channel standard SSI

- Interface: 2-channel standard SSI

- Interface: 2-channel standard SSI