For safely automated machine tools

Machine builders are facing new challenges due to increasing automation and the vision of the smart factory: From individual machine tools to fully networked production systems, flexibility and networking are becoming increasingly important – with the highest safety and quality standards. As a sensor manufacturer, our goal is to make your production even more flexible, efficient, and safer through the use of our innovative products and solutions. This is how we ensure your success in an industry that is ever evolving.

Machine tools and automation systems

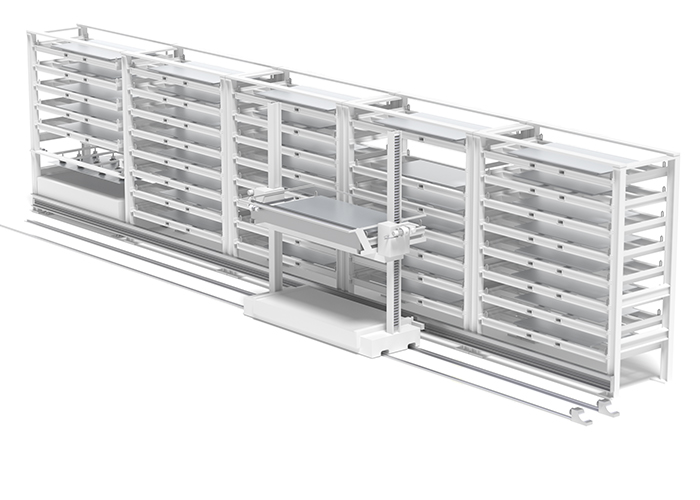

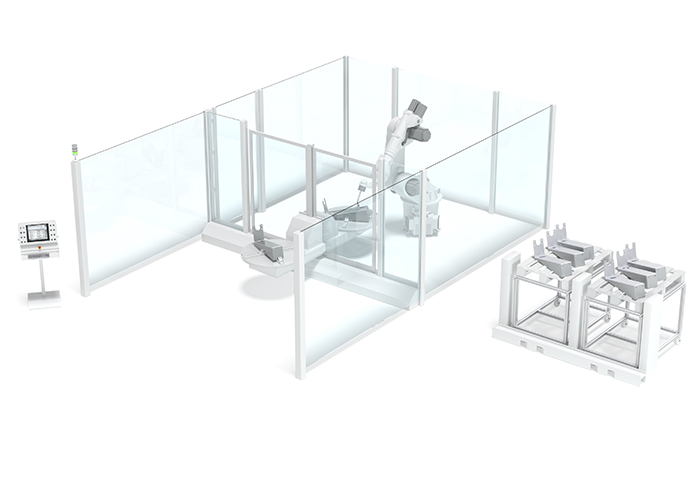

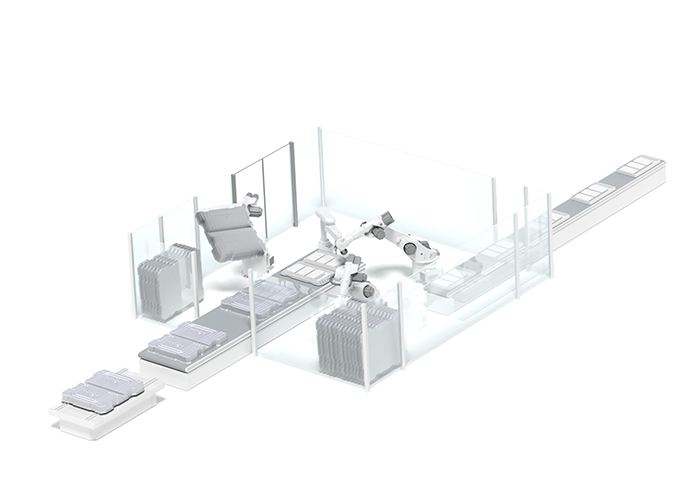

Production of the future is characterized by flexible structures. From the individual machine tools to a production cell or a fully networked production system of a smart factory. What all have in common are the automated and linked processes in and between the cells. This improves productivity, allows for a more efficient use of materials and enables higher product quality. For a while now, sensors are, thus, not only a matter of process control – today they are above all needed for linking processes together.

Maximum system availability and certified quality standards

Our sensors support you in all areas of automation, quality assurance, traceability and machine safety. They are characterized by easy handling during commissioning and exchange. With sophisticated functions, intelligent devices ensure smooth production and material provision. The long-term quality as well as the availability of the sensors are guaranteed. Our products thereby help to ensure and maintain the high availability of the system.

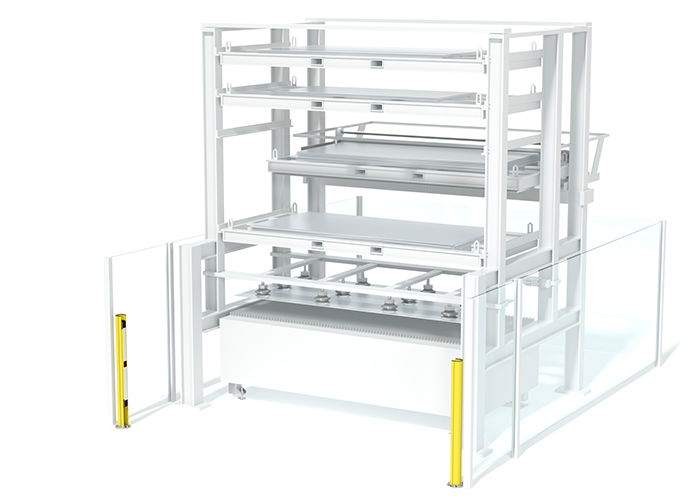

Safety without compromise

The advance of automation gives rise to new requirements with regard to the safety of persons and machines. Through our specific application know-how and more than 30 years of experience in the area of machine safety, we offer unique insight into safety-related applications. With our safety product range consisting of high-quality products, intelligent systems as well as competent technical services, we provide you with targeted answers.