Safety radar system

Safe radar system LBK ISC

Reliable area monitoring in harsh environments and restart protection / up to PL d

Advantages for you

- Reliable operation, even under harsh environmental conditions with, e.g., dirt, dust, smoke, and light

- Flexible adaptation of the protected area to the application: Determine the number and position of the sensors, configure the length and opening angle / width of the area

- Static objects are permitted in the protective field and do not lead to the shutdown of the safety outputs

- Fast integration due to simple system design and controller with PROFIsafe or FSoE interface as well as CIP Safety

- Project planning and setup service for your application by our certified experts on request

Highlights

Reliable operation under demanding environmental conditions

The radar principle is resistant to environmental influences such as dirt, dust, sawdust, smoke, oil, humidity and light. This guarantees reliable operation of the machine even under demanding environmental conditions and avoids unnecessary shutdown.

Function

They monitor the protected area for access by and the presence of persons. Even persons who are standing still are not really ‘static’, and are therefore detected reliably by the sensor.

The 3D radar principle allows areas on steps, pedestals and behind non-metallic shadowing to be monitored as well.

Static objects permitted in protected area

The radar technology reacts sensitively to movements. However, static objects in the monitored area do not cause the safety signal to switch off. Static objects such as pallets, material containers and tool trays are therefore allowed to be placed in the protected area.

Simple and flexible system design

To guard larger areas, a controller evaluates up to 6 sensors. With 4 channel configurations per controller, up to 24 sensors can be used in one application. The system parameters can be simply adapted to the application using the LBK Designer configuration software.

To enable integration into safe fieldbus systems, controllers with PROFIsafe and FSoE interfaces are available. Thus, detailed status information relating to the system can also be queried.

Application

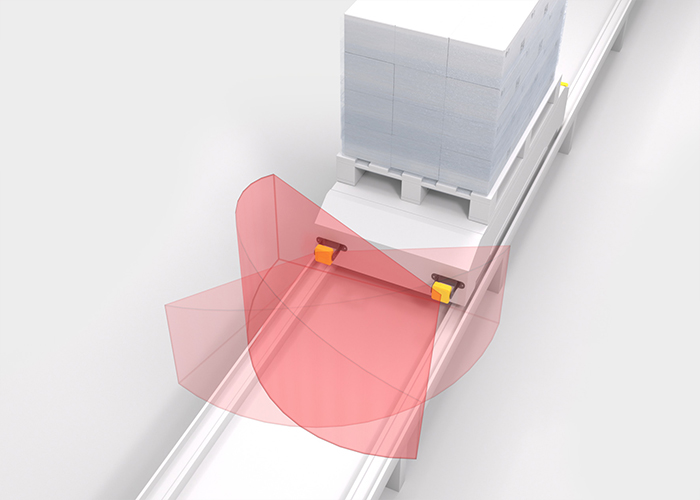

Access guarding at material transfer station

Requirement:

The robot cell is fed automatically. The material is loaded onto the conveyor line, e.g. using a forklift truck, and then transported into the cell. Access to the cell must be safeguarded. To guarantee optimum capacity utilization of the robot cell, the safety concept must also allow uninterrupted operation of the cell during loading.

Solution:

The loading area of the conveyor line is guarded at both the feed and outfeed side by multiple light beam safety devices. The area between the photoelectric sensors is monitored for the presence of persons by safety radar sensors.

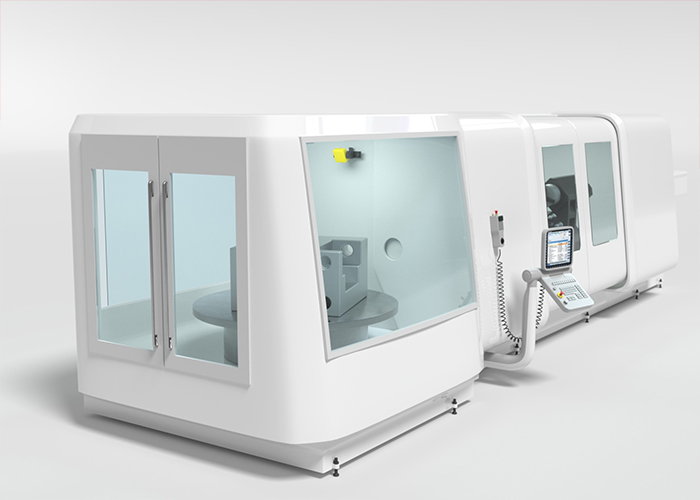

Monitoring of hidden areas in machines

Requirement:

The automatic machining process may only start when the machine openings are closed and nobody is inside. The mechanical processing should not impair the safety function.

Solution:

The radar sensor placed in the processing area reliably detects people even in harsh environments. Usually combined with safety proximity sensors on machine doors and a safety controller, a restart is prevented if the monitoring area is not ‘free’ and the machines are not ‘closed’.

Highly robust transportation path safeguarding in diffuse environments

Requirement:

Safeguarding and detection of persons is to be ensured in open areas or environments with reflective surfaces along the transportation routes of transfer wagons, AGVs or cranes.

Solution:

The LBK radar system’s sensors monitor the transportation route via adjustable lobes with warning and protective fields without any erroneous switching caused by the environment or ambient light, because it only detects people.

Guarding of hazardous areas in harsh environments

Requirement:

The hazardous working range of the machine is to be guarded against entry by and the presence of persons. Safe operation and high availability must also be guaranteed under harsh ambient conditions – such as dirt, welding sparks, sawdust or humidity.

Solution:

The LBK 3D safety radar system detects movements in the monitored area and operates reliably even under harsh environmental conditions. Furthermore, the radar technology allows the presence of static objects in the monitored area.

Restart protection and monitoring of hidden areas

Requirement:

To prevent danger, the process may only be restarted once it has been ensured that no person is present in the working range or in the hidden area.

Solution:

The LBK 3D safety radar system monitors the presence of persons in the protected area and operates reliably even under harsh environmental conditions. Furthermore, the radar technology allows the presence of static objects in the monitored area.

Technical features

| Safe 3D radar system with FMCW modulation for detecting movements | |

| Configurable protected area and warning range, 4 configurable signal outputs | |

| Up to 6 sensors can be combined in one application, dynamic changeover of the configuration during operation |

| Safety | Performance Level PL d, SIL 2 LBK S01: Category 2, LBK SBV-x: Category 3 |

|

| Operating range | LBK S01: 4 m, LBK-SBV-01/201: 5 m, LBK SBV205: 9 m | |

| Angle of radiation (horizontal / vertical) | LBK S01: 50° / 15° or 110° / 30° LBK SBV-x: 10°… 100° / 20° |

|

| Frequency range | LBK S01: 24 GHz, LBK-SBV-x: 60 GHz | |

| Environmental conditions | Temperature range: -30°C ... 60°C, sensor protection class: IP 67 | |

| Controller with I/O interfaces, optional: SD card slot |

Safety: 2x OSSDs Configuration and diagnosis: Micro USB, optional: Ethernet TCP/IP |

|

| Controller with safe fieldbus interface, optional: SD card slot |

Safety: PROFIsafe or FSoE, CIP Safety, 2x OSSDs Configuration and diagnosis: Micro-USB, TCP/IP |

Article list

- Shape of the detection fields: asymm. conical/square

- Shape of the detection fields: asymm. conical/square