Dynamic reference diffuse sensors

DRT 25C - The one for everything.

Reliable detection.

Without readjustment when changing objects.

The DRT 25C dynamic reference diffuse sensor is an innovative new product from Leuze. Thanks to intelligent CAT technology it reliably recognizes flat and spherical-shaped products, transparent to high-gloss films as well as irregular shapes and contours.

Advantages for you

- The reliable detection of objects even with difficult shapes and surfaces ensures continuous machine output and prevents downtime

- No adjustment of the sensor is needed when products or packaging materials are changed, shorter setup times enable higher production quantities

- Fast and easy setup of the sensor through automatic teaching of the belt surface using the teach button; just one universal mounting position for all objects

- Reliable operation even if the conveyor belt is soiled or vibrating

- IO-Link for easy integration of additional functions in the machine control, such as warning message in case of excessive contamination, use of the counter built into the sensor, or locking of the teach button

Sensors must safely detect a wide variety of products and films on the conveyor belts of packaging machines (HFFS, FS, Thermoform, and VFFS). In addition, they must work continuously after a product changeover, without requiring further setup. Optical sensors that perform these tasks are typically retro-reflective sensors that operate with foreground suppression. This technology has its weaknesses, however, especially when detecting flat, glossy or transparent objects.

The innovative detection method of the DRT 25C, on the other hand, works with Contrast Adaptive Teach technology, CAT for short, whereby the conveyor belt is used as a reference instead of the product. This is how the reference diffuse sensor detects any type of object as a 'deviation' to the conveyor belt surface. The detection is independent of the surface characteristics of the products, such as the color, gloss, and transparency, which most diffuse reflection sensors have problems with.

Highlights

The better diffuse sensor

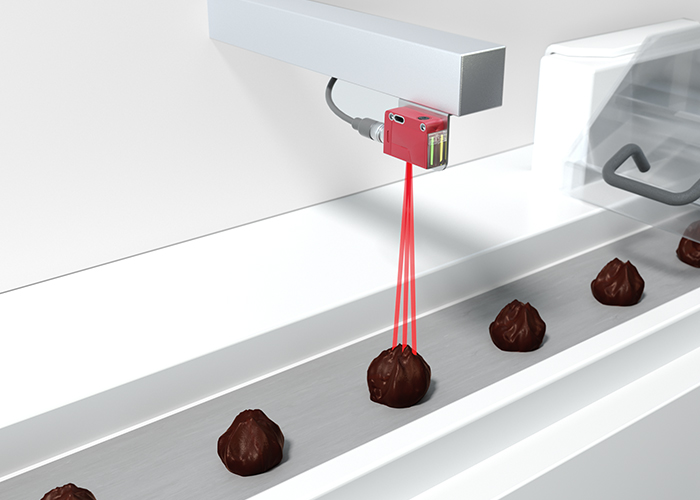

No matter what shape the products and their packaging have: With its three light beams, the DRT 25C reliably detects the front edges of the objects and ensures that the process goes smoothly without any machine downtime. Thanks to the wide scan, even products with holes, such as cookie curls, are safely detected as a continuous object. For this, not all three light spots need to be on the object.

From transparent to high-gloss

Packagings with different colors and transparency are safely detected as a "deviation" from the conveyor belt surface due to the reference technology. This means that even machines that process a wide range of films can be equipped with a single sensor type.

No setup time when changing products

When performing the initial setup, the conveyor belt surface is taught in as a point of reference with the teach button. After a product changeover, it is not necessary to adjust this setting, as the point of reference remains the same. In addition, the mounting position and the alignment of the sensor itself can be continuously used for the widest variety of objects. This means that no setup effort is required for the sensor when changing products.

One-of-a-kind CAT technology

The DRT 25C works with the conveyor belt surface as a dynamic reference for the detection of objects. With this method, the surface characteristics of the conveyor belt are taught in via the teach button. The sensor will then detect all objects that do not correspond to the conveyor belt surface. The DRT 25C thereby functions independent of object, making it more stable than classic diffuse reflection sensors. Even contamination on the conveyor belt can be compensated with the Contrast Adaptive Teach technology.

Applications

Detection of products on conveyor belts of primary packaging machines

Requirement:

To control the buffer section and the weld bar, the front edges of the products on the conveyor belt must be reliably detected. The sensor must also reliably detect products with challenging dimensions from very flat to very tall, in order to prevent machine stoppages due to incorrect detection. The sensor must be easy to set up for all products.

Solution:

The DRT 25C reliably detects anything, from small and flat to tall and spherical-shaped products, even if the shapes and contours are irregular. This means that machines can be fitted with a single sensor regardless of the application. The single button teach function also makes the DRT 25C easy to set up.

Detection of thermoformed trays

Requirement:

After products have been packaged in thermoformed trays, for example, the front edge must be reliably detected from above, even in single or multiple track systems. Different heights of the trays can pose a challenge for the sensor system used.

Solution:

The DRT 25C dynamic reference diffuse sensor sets the conveyor belt as a reference and thus allows for reliable detection of the front leading edges of the object on the belt - independent of the colors or heights of the products. Light spots arranged horizontal to the transport direction also detect products with gaps.

Detection of products on conveyor belts of secondary packaging machines

For trouble-free control of the buffer section, packaging made of various materials and with a wide variety of surfaces must be reliably detected from the front edge. Changing products or packaging films should not require any additional setup and adjustment work on the sensor.

The unique technology of the DRT 25C uses the conveyor belt surface as the point of reference. The detection is independent of the surface characteristics of the materials used, such as the color, gloss, and transparency. This means no setup work on the sensor is required when changing products.

Detection of containers

If bottles and cans are shrink-wrapped into packages using film, they must also be detected on multitrack conveyors. Different types of packages with transparent film or different film printing are to be reliably detected.

The DRT25C.R unit pack sensor uses the surface of the conveyor belt as a reference. As a result, it reliably detects the complete range of package types. Therefore, no adaptations to the sensor are necessary when changing products.

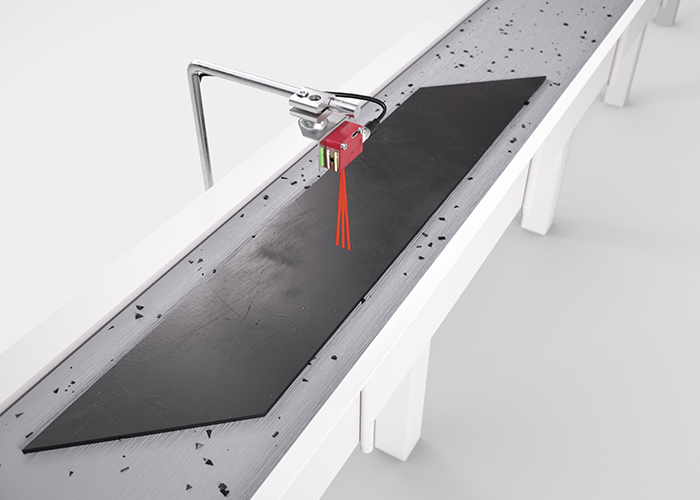

Detection of rubber parts

Requirement:

Black rubber is difficult to detect optically due to its low reflectivity. In addition, heavy contamination of the conveyors during the production process makes detection more difficult.

Solution:

The DRT 25C and DRT 35C reference diffuse sensors use the conveying belt as a reference, which allows even extremely dark objects to be reliably detected – even in heavily contaminated environmental conditions. The teach function with 2 or 3 adjustable sensitivity levels enables quick and convenient adaptation to different process conditions.

Technical properties

- Reference technology and three LED light spots for reliable object detection with the widest variety of shapes and surfaces

- Unit pack sensor developed especially for detecting film-wrapped bottle or can packs

- Large working range for conveyor belt spacings of 50-450 mm

- High switching frequency of 750 Hz for belt speeds up to 2 m/s

- Easy configuration via an operating button (teach button)

- IO-Link interface for standardized communication with the machine control in the dual channel principle or in SIO mode

- Compact housing: only 15 mm x 42.7 mm x 30 mm for universal use

- Protection classes IP 67 and IP 69K and ECOLAB certification

Article list

- Series: 35C

- Operating principle: Reference teach on reference surface (plastic roll...

- Operating range, max.: 0.08 ... 0.4 m

- Switching output: Transistor, PNP

- Series: 35C

- Operating principle: Reference teach on reference surface (plastic roll...

- Operating range, max.: 0.08 ... 0.4 m

- Switching output: Transistor, Push-pull

- Series: 35C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, PNP

- Series: 35C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, PNP

- Series: 35C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, PNP

- Series: 35C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, PNP

- Series: 35C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, PNP

- Series: 35C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, PNP

- Series: 33C

- Operating principle: Reference teach on reference surface (plastic roll...

- Operating range, max.: 0.08 ... 0.4 m

- Switching output: Transistor, Push-pull

- Series: 33C

- Operating principle: Reference teach on reference surface (plastic roll...

- Operating range, max.: 0.08 ... 0.4 m

- Switching output: Transistor, Push-pull

- Series: 33C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, Push-pull

- Series: 33C

- Operating principle: Reference teach on background

- Operating range, max.: 0.05 ... 0.15 m

- Switching output: Transistor, Push-pull