More precision for optical distance sensors thanks to AI

Leuze uses modern artificial intelligence (AI) methods to significantly improve the measuring accuracy of optical distance sensors. This innovation reduces measurement uncertainty by half without the need for additional computing resources during operation. All computing effort is performed during the production phase. The methodology developed forms the basis for a new generation of precise optical distance sensors.

The distance measurement challenge: The effect of the object surface

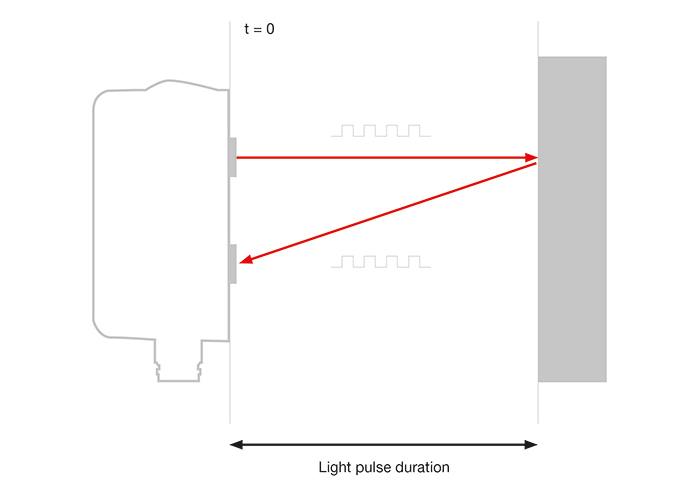

Optical distance sensors can use time-of-flight (TOF) technology to measure how far away an object is by emitting light and measuring the time it takes for the reflected light to return.

TOF distance sensors measure distances by emitting light and recording the time the reflected signal takes to return.

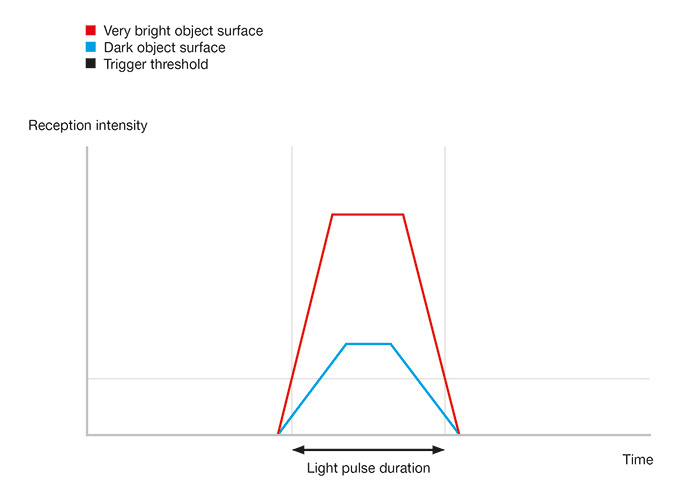

This is achieved by emitting short light pulses, the reflection of which is received back from the object. The distance is calculated from the light pulse’s travel time – from when it is sent to when the return signal is detected. The object surface’s reflectivity influences both the amplitude and the shape of the electronic reception signal. This leads to varying times of signal detection times and different pulse widths. Bright surfaces generate stronger signals with a wider pulse width and earlier detection, while dark surfaces cause weaker, narrower pulses and later detection.

This means that the returning signal will vary in strength depending on the surface of the object – for example, light or dark. This can lead to measurement errors.

The strength of the reflected light signal varies depending on the object surface’s brightness

Previous solution approach: Calculation models

Until recently, a classic mathematical model was used to correct these errors: A correction value is calculated for many different surfaces and distances, which is then applied automatically later. This model is based on a so-called polynomial function.

New solution: AI takes over the correction

Instead of working with rigid formulas, Leuze now uses a neural network – a form of artificial intelligence. It uses sample data to learn how brightness and surface texture affect measurements, enabling it to correct the measured values much more accurately.

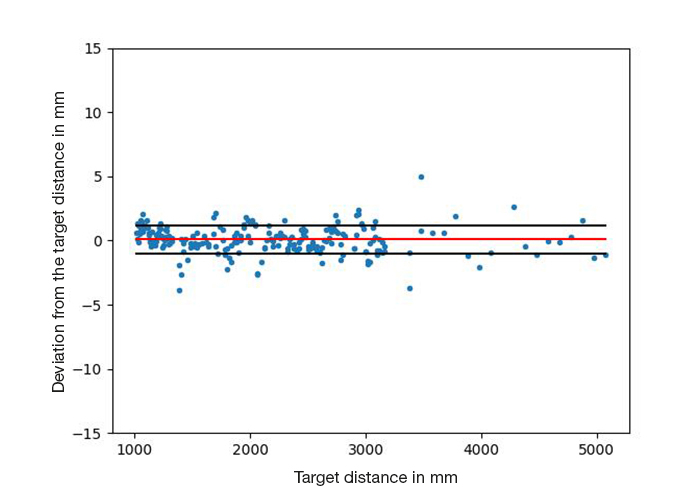

Deviation from the target distance after correction using neural network

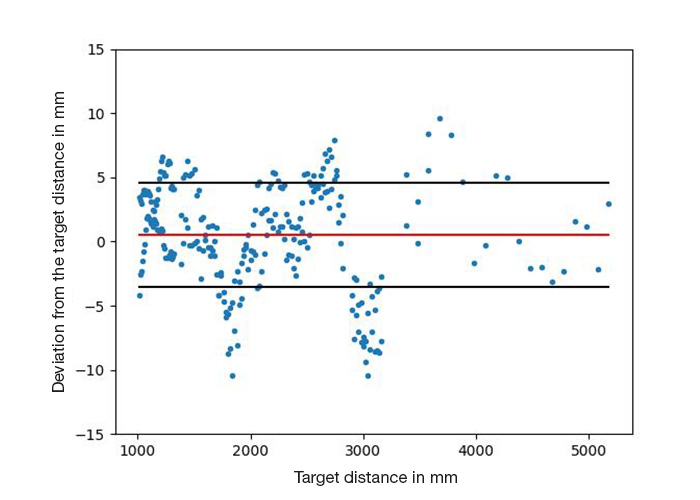

Deviation from target distance after correction by 5th order polynomial

Advantages of the neural network

- Can be flexibly adapted to different sensor types and surfaces

- Learns better from real data, even with strongly oscillating 3D curve characteristics

- Provides significantly more precise results

Technology in the background – simply explained

Many measured values are collected during the production process: for light, dark and differently textured surfaces as well as for different distances. These measured values are communicated to the production facility’s control system. From this, the production facility’s neural network calculates the necessary correction values for the sensor. The sensor then requires no additional computing power during operation – the AI has already “learned” everything.

The result: Fewer errors, more reliability

Tests show that the new method reduces systematic measurement errors (i.e. the dependence of measurement results on surface and distance) by more than half through AI-based calibration. That means that the sensor measures more reliably, even on difficult surfaces.

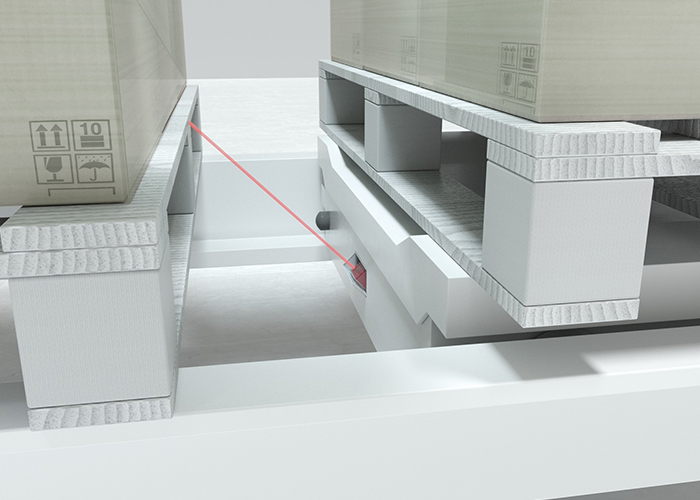

Distance sensors in intralogistics: To ensure a defined distance between the pallets, the distance between the shuttle and the stored pallet must be precisely determined regardless of surfaces, colors or angles.

Precise measurement required: When picking up the pallet, the distance between the pallet and the end face of the load receptacle must be precisely determined in order to stop the forward movement in good time.

Your benefits at a glance

- Fewer measurement errors – more reliable results

- No additional computing load during operation

- Flexible use with different materials

- Future-proof – with the use of modern AI

Summary

Leuze is taking the precision of optical distance sensors to a new level with the use of artificial intelligence. Customers benefit from more robust and accurate measurements – without any effort during operation. The combination of intelligent calibration and efficient use makes this solution ideal for demanding industrial applications.