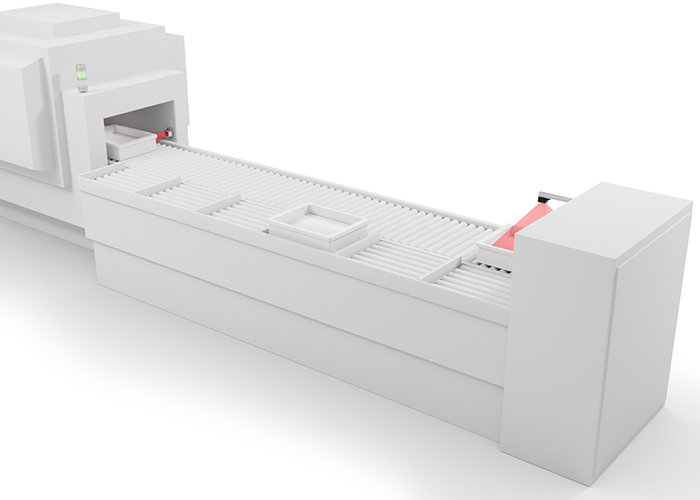

Sensor solutions for hand luggage security checks

Combined with the security check, hand luggage is packed into transport containers and automatically screened. For this, the assignment of an output location for the transport container is linked to the X-ray image.

Tray tracking

Requirement:

Once the trays are filled, their assignment during the security check must be unique and tamper-proof, regardless of the contents.

Solution:

After being placed on the conveyor, the trays are identified using RFID. Devices with compact dimensions and international approval such as the RDH 200 are ideal for this.

Tray recognition

Requirement:

The trays should be detected in sections along the gravity or roller conveyor, among other things to detect jams and control the output.

Solution:

Cylindrical diffuse sensors with invisible light beams to avoid irritation, such as the ET 328I, can be easily integrated between or next to the rollers to detect the containers.

Checking the empty status at the tray return

Requirement:

At the end of the hand luggage check, it must be ensured that the trays are empty before they are automatically returned and the process starts again.

Solution:

A Simple Vision Sensor IVS 1000i can be configured in just a few clicks to check whether the trays are empty before issuing a release signal for their return transport.