Assembly line using e-mobility as an example

On assembly lines, components and products are manufactured through successive assembly processes. Depending on requirements, everything from small, partially automated lines to fully automated lines are used.

In the area of e-mobility, the installation of battery cells, modules and packs is usually fully automated. The "tracking and tracing" of the components, transport- and logistics solutions for material supply of the assembly cells and the safety of the work stations determine the requirements on the sensors.

Our components guarantee smooth processes and ensure machine safety. Typical areas of use are code reading and identification for the traceability, object detection for automation as well as access guarding at the assembly cells.

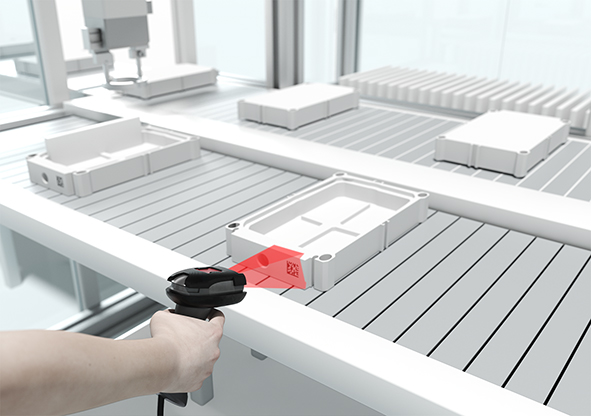

Requirement:

The order and the batch are to be detected at the start of battery production and stored for the further course of action. To do this, the processing steps and all relevant components are to be identified using a bar code.

Solution:

Mobile code readers are well suited for detecting the orders and the batches. Wireless models like the IT 1991i make operation easy and comfortable. Depending on the control concept, they are connected directly to a PC or – for integration via common fieldbus and Ethernet interfaces – to the MA 200i modular connection unit.

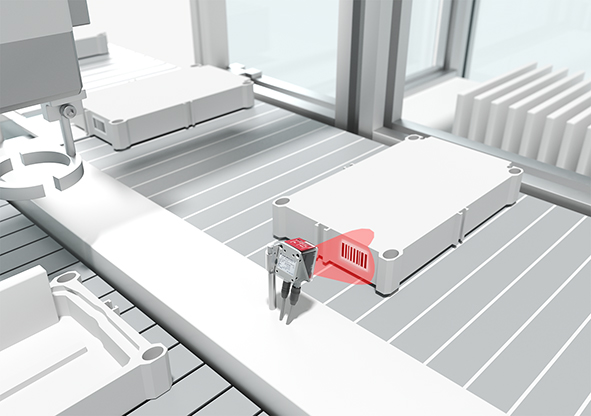

Requirement:

The "track and trace" concept also includes the traceability of each individual battery cell that is in the work system for processing. Depending on the used system, the 1D- or 2D-code affixed to the cell is to be captured.

Solution:

The DCR 200i code readers and the LSIS 400i smart cameras reliably identify 1D- and 2D-codes. The DCR 200i are characterized by their compact design and simple commissioning. The LSIS 400i operate especially flexibly. If, for example, the reading distance changes, the focus and the field of view can be adapted online using a browser.

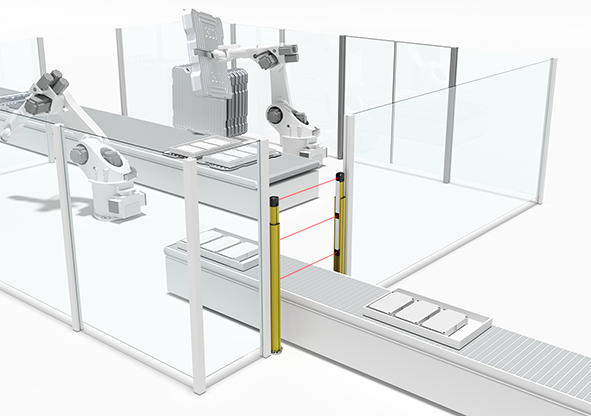

Requirement:

The battery components are moved from one robot assembly cell to the next via the conveyor system. The entrances and exits to the robot cells must be secured against access.

Solution:

The MLD 500 multiple light beam safety devices secure access at conveyor lines. Depending on requirements, e.g., installation situation and size of the transport material, models are available with and without muting function. Configuration is easily performed via the pin assignment. With the integrated muting function, no additional devices are necessary.

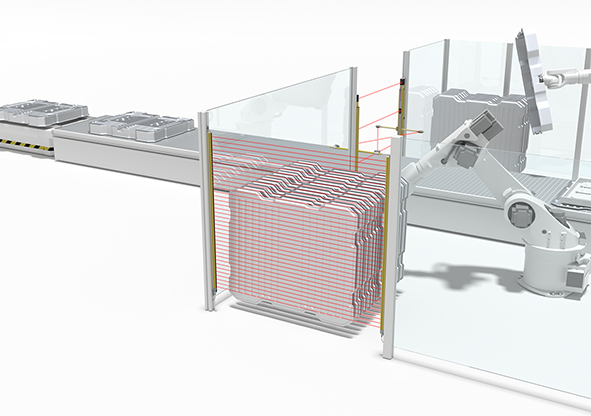

Requirement:

Even on automatic operating systems, it can be necessary for the operating personnel to intervene. Because easy access is required in these cases, optical safety sensors are to be used. To keep the designs of the system as compact as possible, the sensors should enable short safety distances.

Solution:

With their resolution of 14 mm, the MLC 510 safety light curtains offer the shortest possible safety distances. Various mounting options and protective field lengths of up to 3,000 mm ensure simple and tailored integration of the devices. For European requirements, the devices feature AIDA-compliant pin assignment.

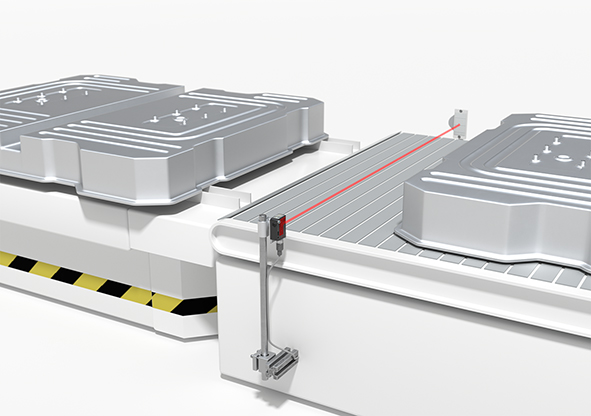

Requirement:

The production systems for battery production are linked by means of conveyor systems. The products are fed to the next process step either directly on these or in trays. To allow the products to be removed by the gripper robot or transferred to an AGV, the conveyor line must be controlled through detection of the products.

Solution:

The universally usable PRK 15 and PRK 25C retro-reflective photoelectric sensors offer high function reserves for high system availability. With their bright light spot, they can be adjusted quickly and easily. Additional functions, such as warning output and activation input, increase process reliability.

Requirement:

The transportation path of the AGV must be guarded by means of safety sensors. The protective fields are to be flexibly adapted to the movement and loading situation. If the principle of natural navigation is used, the device is at the same time to provide the measurement data for the navigation software.

Solution:

The RSL 400 safety laser scanners merge safety technology and high-quality measurement value output in a single device. They have a scanning range of 270° and 100 reversible field pairs. Two scanners therefore provide optimum guarding of the AGV. The measurement data has a high angular resolution of 0.1° and a low measurement error.