Processing Center

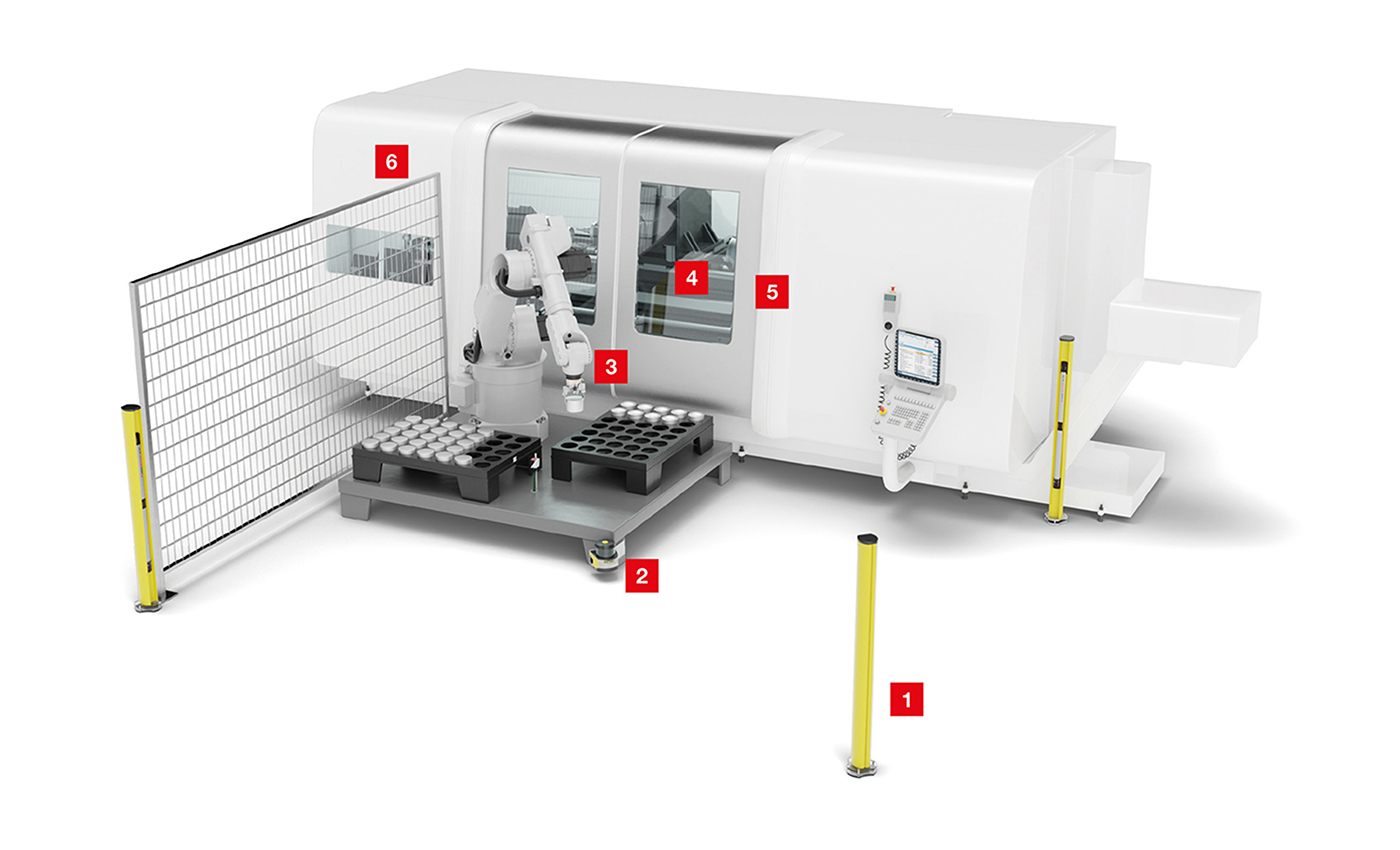

In machining centers, objects of various materials are machined, turned, and drilled. The prerequisite for processing work pieces in complex machining centers with a high degree of precision is having the right tool available for each work step. Industrial robots are often used for the automated loading and unloading of processing centers. Before the robot picks up a part, the part must be uniquely identified to ensure that the correct processing step is carried out. The robots perform numerous swivel and gripping movements in a very short period of time. The working ranges of the robots must be reliably safeguarded in terms of access by and the presence of persons.

Our inductive and optical sensors check and monitor the presence and position of work pieces and parts.

Our identification systems record data for the traceability of those work pieces and parts and for the next work step. And our safety sensors reliably monitor danger zones and safeguard points of operation.

Requirement:

Access to the working range is to be guarded while the machine is in operation. To enable material entry and exit, the machine must be easily accessible from multiple sides.

Solution:

The MLD 300/500 multiple light beam safety devices in combination with the UMC mirror columns safeguard access to the machine on multiple sides and over lengths of up to 70 m. The integrated laser alignment aid makes installation quick and easy.

Requirement:

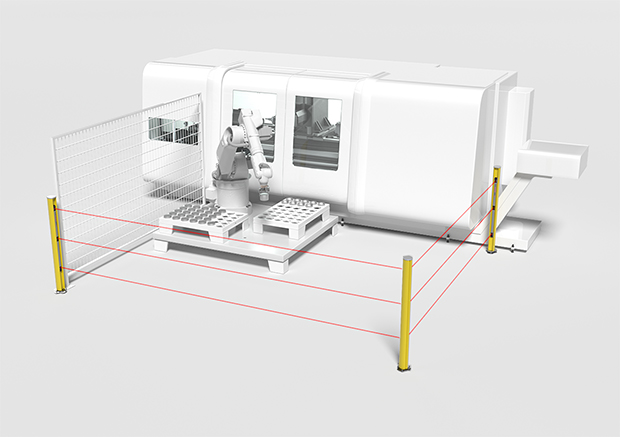

The hazardous working range of the robot is to be guarded against entry by and the presence of persons. The interaction of man and machine requires efficient structuring of the processes.

Solution:

The RSL 400 safety laser scanners monitor the working range of the robot and enable simple access to the machine. Because the presence of persons is also monitored, an automatic start-up of the robot can be integrated in the processes.

Requirement:

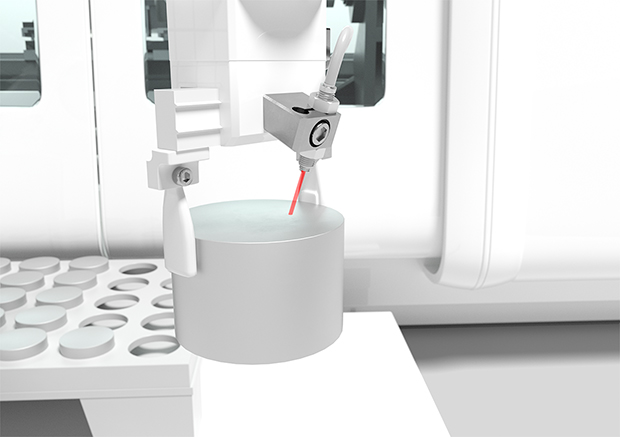

During the automatic loading of the processing center, an industrial robot performs numerous swivel and gripping movements in a very short period of time. During the gripping movement, inductive and optical sensors check and monitor the presence and position of work pieces and parts.

Solution:

Due to the constrained space, the fiber optic sensors such as the LV / KF series are ideally suited for this application. Depending on the contour of the part/work piece, various beam exits are available. The fiber-optic product range is rounded out by the dual display of the amplifier for convenient commissioning.

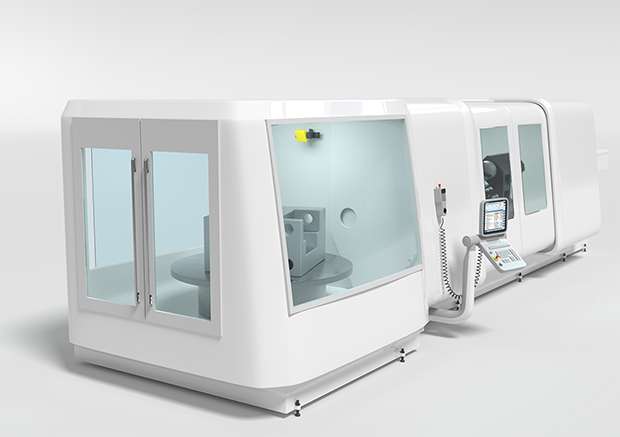

Requirement:

The machine room is to be visually monitored. This also applies for areas that cannot be viewed from the outside. Due to the special environmental conditions, an industrial camera with high degree of protection is required.

Solution:

The LCAM 408i color camera is optimized for use in harsh, industrial environments. 5-megapixel image resolution and Gigabit Ethernet interface ensure high image quality and fast, live-image transfer. The metal housing with degree of protection IP 67 and models with compressed air connection guarantee reliable operation.

Requirement:

The point of operation that arises from opening the safety doors must be safeguarded. Ideally, the optical protective device can easily be integrated in the machine in a space-saving manner.

Solution:

The MLC 520S safety light curtains have an especially narrow design. Together with the finely graduated length selection in increments of 30 mm and the design without dead zones, the devices can be perfectly integrated in the machine assembly.

Requirement:

During the fully automatic loading of processing centers by means of AGVs, it must be ensured that no persons are located in the interior before the process is allowed to restart. This also applies for areas of large processing centers that are difficult to see.

Solution:

The LBK 3D safety radar system detects persons in the monitored area and operates reliably even under harsh ambient conditions. Furthermore, the radar technology allows the presence of static objects in the monitored area.