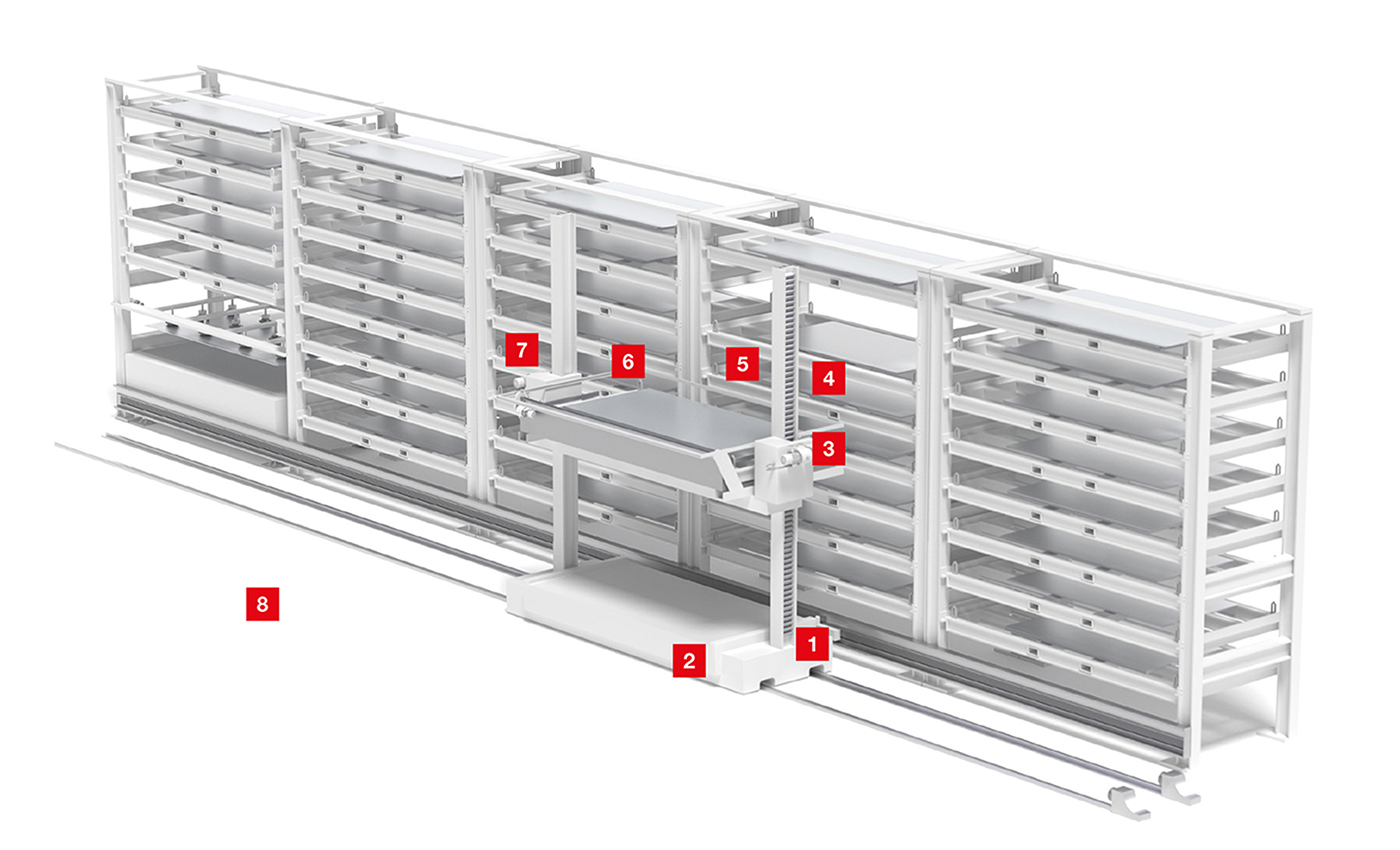

Storage system with stacker crane

Flexible storage systems make a significant contribution to the automation of production processes. In high-bay warehouses, the performance of the stacker cranes is especially important. They perform the automatic storage and retrieval of materials such as sheet metal plates and long goods. Their speed and reliability are, thus, decisive for the overall performance and availability of the systems.

Our sensor solutions enable optimum operation of the stacker cranes. They capture position data in the travel/lifting area and optically transmit travel commands and position data to the control. In addition, our sensors perform the compartment occupation check and prevent material from being pushed through. Reliable operation and high availability of the system are thereby ensured.

Requirement:

The stacker crane or load receptacle must be positioned in the X-direction (travel axis) and Y-direction (lifting axis) accordingly for the pallet to be approached.

Solution:

The BPS 300i compact bar code positioning systems enable exact positioning. Interfaces for fieldbuses, industrial Ethernet as well as SSI or serial connections make integration in the control simple and flexible. The configuration and diagnosis of the devices are just as easy.

Requirement:

The stacker crane or load receptacle must be appropriately positioned in the X-direction (travel axis) and Y-direction (lifting axis). Travel commands and positioning data are to be optically transferred to the control to ensure high availability of the system.

Solution:

The AMS 300i laser distance measurement devices are used for the exact positioning. The DDLS 500i data transmission photoelectric sensors function fault-free without offset directly next to the AMS 300i devices. Selectable operating ranges, interfaces and protocols ensure optimum solutions.

Requirement:

Following rough positioning, additional optical sensors are used for the compartment fine positioning of a stacker crane in the horizontal (X) and vertical (Y) direction.

Solution:

The camera-based IPS 200i are predestined for compartment fine positioning. Extremely small size, simple operation and configuration via the integrated web server are a few of the highlights of the series. The data is transferred to the control via the integrated Ethernet TCP/IP or PROFINET interface.

Requirement:

Before the material is transferred, the correct position of the load receptacle in front of the storage location is to be checked in the horizontal and vertical direction (compartment fine positioning). This is to be performed by optically sensing the column or the bar edge.

Solution:

The HT 46C diffuse reflection sensors with background suppression are used for positioning the load receptacle. A wide range of profile types as well as color or glossy surfaces are reliably detected. Thanks to the optimized beam path, the sensors function reliably even in the case of columns with holes.

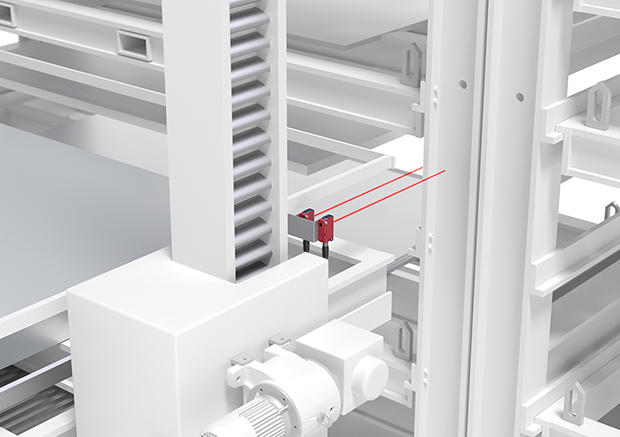

Requirement:

Before a pallet or a cassette can be stored in a rack, a check must be performed to determine whether the rack is empty. When retrieving, on the other hand, it is necessary to monitor the entry of the telescopic arm or fork to ensure that the stored material is not pushed in the wrong direction.

Solution:

Thanks to their focused laser, sensors ODS 9, ODS / HT 10 and HT 110 detect the cassette at an operating range of up to eight meters. With switching product models, the movement of the cassette can be detected with the help of the window function.

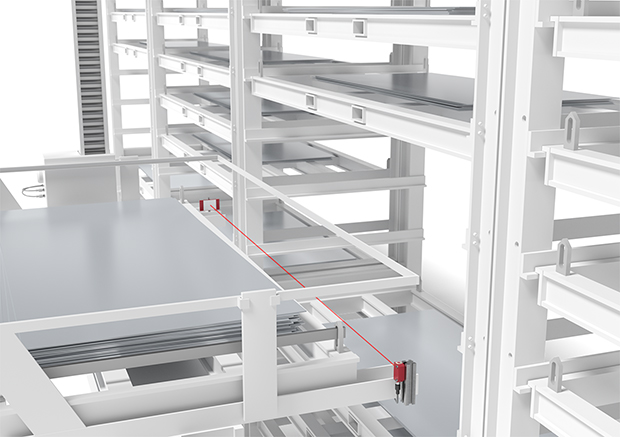

Requirement:

During a material movement, the cassette with the sheet metal plates, for example, is checked for presence. Especially after retrieval, a check must be performed to ensure that the load receptacle has completely pulled in the material in order to avoid collisions and downtime.

Solution:

In addition to large operating ranges and increased function reserves, series 3 is also characterized by simple handling. Thus, the devices stand for reliable object detection even with thin sheet metal plates. The optional IO-Link interface provides additional benefits, such as fast commissioning and diagnostics functions.

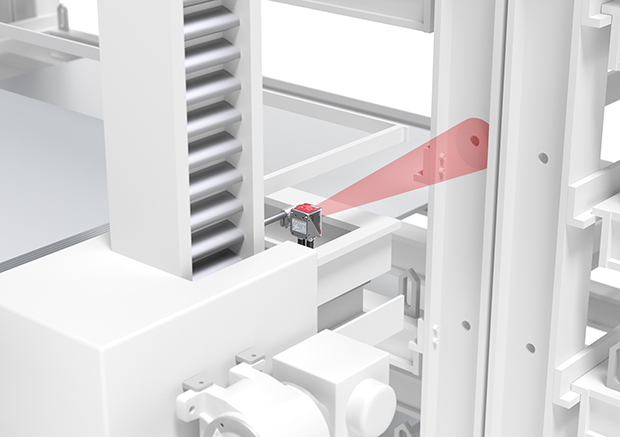

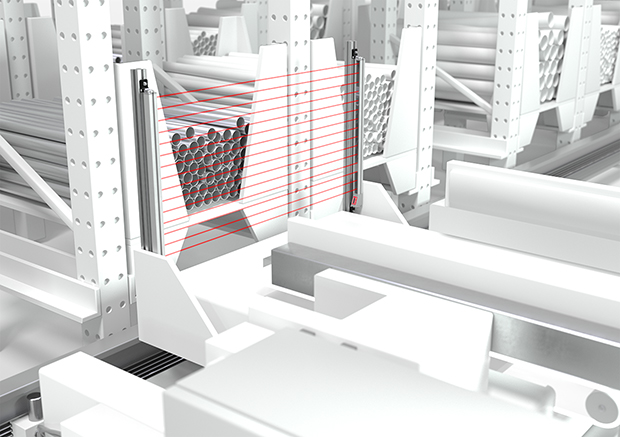

Requirement:

After loading, e.g., a cassette on the load receptacle, a check is to be performed to determine whether the cassette or material is protruding and thereby posing a risk of collision. An optical sensor is to monitor a large surface on the load receptacle here and ensure reliable operation.

Solution:

The CSL 710 switching light curtains monitor large areas and convince with their ease of configuration and large function reserves. Various fastening materials enable optimum integration. Alternatively, the CML 700i measuring light curtains with integrated PROFINET or PROFIBUS interface are available.

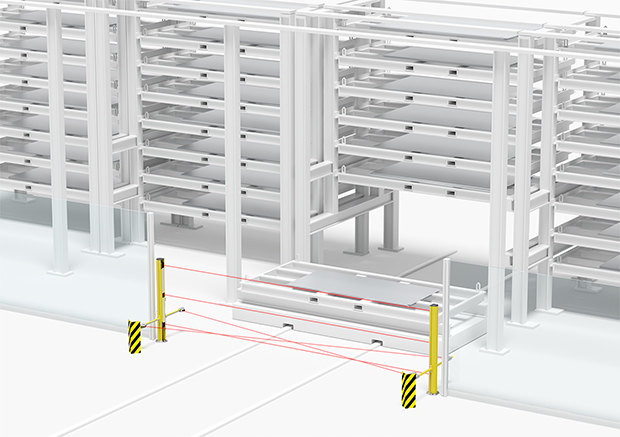

Requirement:

Access guarding on conveyor lines is to prevent persons from accessing the danger zone, while at the same time allowing the transported goods to pass through.

Solution:

The muting function bridges the safety sensor in a controlled manner to allow the transported goods to pass through. This function is already integrated in the MLD 500 multiple light beam safety devices and the MLC 500 safety light curtains. The MSI-MD-FB muting interface and MSI 400 safety control provide an external muting control.