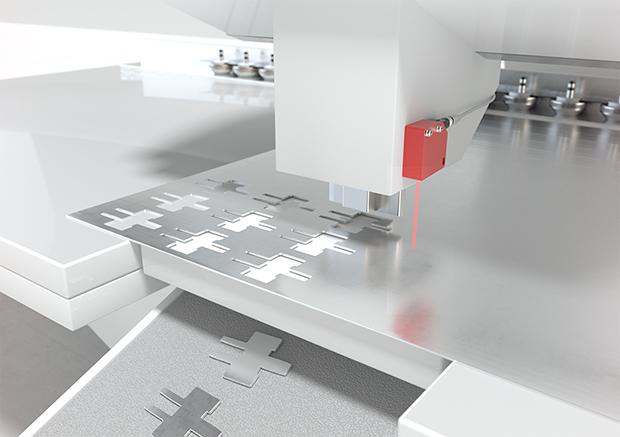

Punching machine and laser-cutting machine

Punching machines and laser-cutting machines separate very quickly and precisely smaller parts from large sheet metal plates. When processing sheet metal plates with punch presses or with laser cutting, safety at work plays an important role, as work is performed with high pressure and high-energy laser beams. In addition, the sensor system used must be able to detect very small stamping parts to ensure a fault-free production process.

Our sensor solutions reliably and flexibly safeguard hazardous areas. And do so with maximum protection for people and with minimal influence on the workflows. Moreover, sensors check for tool availability, prevent collisions and monitor the ejection of the sheet metal parts being processed.

Requirement:

Access to a dangerous area at a machine or system is to be guarded. To enable material entry and exit, the machine must be easily accessible from one side.

Solution:

The MLD 300 / 500 multiple light beam safety devices offer affordable access guarding solutions. The transceiver models with an operating range of up to 8 m are especially easy to install. For wide-area guarding, transmitter/receiver models are available with a larger operating range.

Requirement:

Access to the working range is to be guarded while the machine is in operation. To enable material entry and exit, the machine must be easily accessible from multiple sides.

Solution:

The MLD 300/500 multiple light beam safety devices in combination with the UMC mirror columns safeguard access to the machine on multiple sides and over lengths of up to 70 m. The integrated laser alignment aid makes installation quick and easy.

Requirements:

After the punching or laser process, the produced parts are guided to a collection container via a chute. The reaching of the maximum permissible fill level of the container is to be monitored. Monitoring must function reliably with oily and glossy surfaces on the parts as well.

Solution:

The CSL 710 switching light curtains convince with their ease of configuration and large function reserves – even with extremely small parts. Various fastening materials enable optimum mechanical integration in the machine. For applications with IO-Link interface, the CML 700 measuring light curtains are available.

Requirement:

On a punching machine, the presence of the punching head in the tool holder is to be checked following the tool change. The check is performed before the actual punching process is started. This serves to avoid downtime and ensures an optimum punching process.

Solution:

The fiber optic sensors of the LV/KF series are particularly well suited for use in constrained spaces thanks to their flexible fiber optics. Depending on the contour of the punching head, various beam exits are available. The parallel display of signal and switching threshold on the amplifier ensures fast commissioning.

Requirement:

To ensure an optimum punching process, the material thickness must be checked. This is performed by measuring the distance to the material with high resolution.

Solution:

The ODSL 8 and ODS 9 sensors measure the distance with resolutions of up to 0.01 mm and thereby supply the basis for a high quality of this process step.

Requirement:

To ensure clear identification for a reliable tool change, a 2D-code is applied to the work piece, i.e. the punching head.

Solution:

The DCR 200i code readers and the LSIS 400i smart cameras read 2D-codes. The DCR 200i are characterized by their compact design and simple commissioning. Their optics models enable different reading ranges. With the motor-driven focus adjustment, the LSIS 400i offer a large and flexibly adjustable reading field.