Integrated connectivity

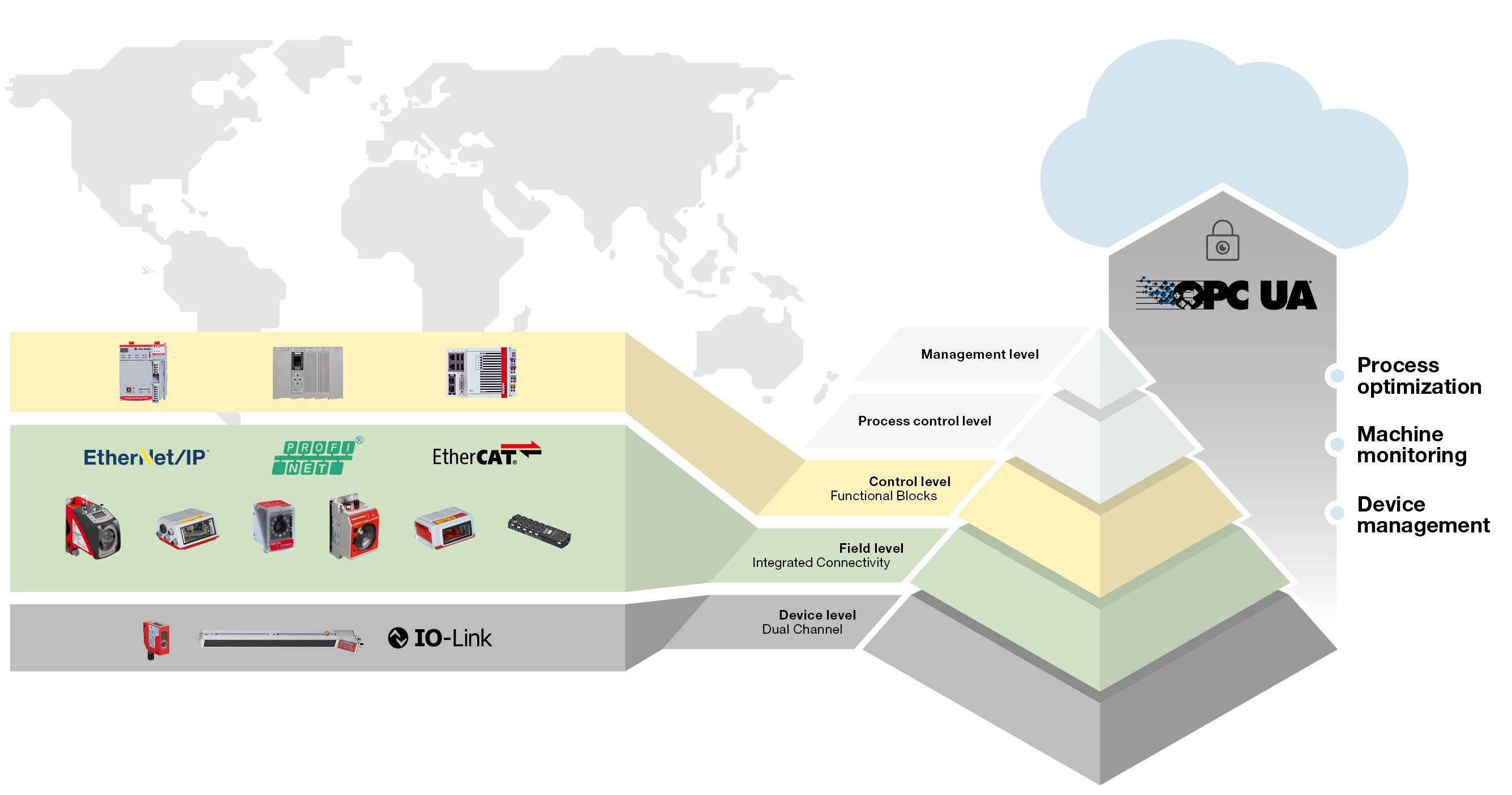

If sensor and interface work together perfectly in a system, it creates advantages for commissioning, machine monitoring and process optimization. Leuze makes it possible with the "integrated connectivity" concept.

It's all in the sensor

Integrated connectivity means: All relevant industrial Ethernet interfaces are integrated in the sensor, making it possible to access the central device functions. It sounds simple, but is not standard on the market. Instead, manufacturers frequently offer devices without an industrial Ethernet interface to save development effort. In such cases, the interface is provided via a gateway. The reason why this is not the optimal solution and why integrated connectivity from Leuze provides system operators with multiple benefits is illustrated in the following examples. The advantages range from commissioning (device management) to machine monitoring (condition monitoring) to process optimization.

Advantages of integrated connectivity for device management, condition monitoring and process optimization

Considerably leaner system layout

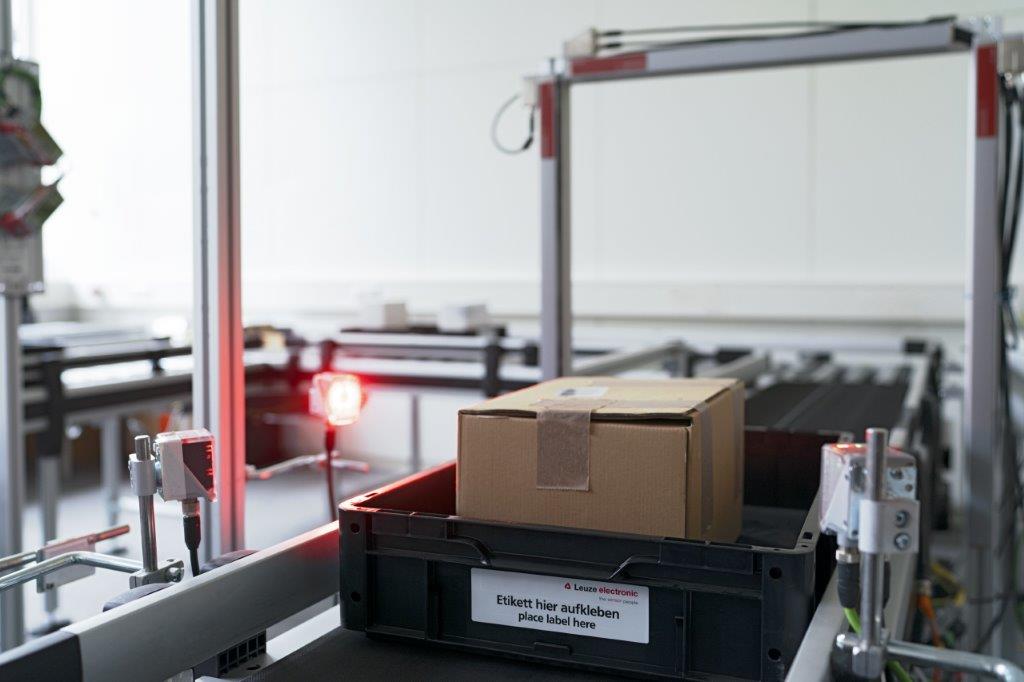

Leuze offers devices with integrated interfaces for PROFINET, Ethernet/IP and EtherCAT. The significant advantage that can already be gained during commissioning is demonstrated using an illustrative system design with and without integrated connectivity. First a system with bar code readers without integrated interfaces: here, every scanner must be connected to a separate gateway - this means an additional gateway with its own power supply for each bar code reader. As a result, the installation effort and the number of cables are double of what is required. The parameterization is also significantly more complex. And not to forget: Because of the gateways required, there are significantly more devices in the system that can cause a malfunction and have to be checked should this occur. In comparison, the same system with integrated connectivity: The industrial Ethernet interface is already integrated in every bar code reader. This means that separate gateways are superfluous. Most importantly, the system layout is significantly clearer and fewer cables are required. Last but not least, errors can be eliminated more quickly as fewer devices have to be checked.

The bar code readers from Leuze's BCL series are equipped with integrated connectivity.

Switch included

Leuze sensors with integrated connectivity also have an additional feature that contributes to particularly efficient commissioning: the devices have a switch as standard, i.e. an Ethernet input port and output port each. As a result, system operators do not need an external switch. In addition, it is much easier to connect several devices, for example in a ring or linear topology. With linear wiring, the system operator connects one sensor to the next using the integrated switches. Only the last sensor in the row is connected to the control. Again, the benefits are the simplified system design and reduced number of cables. Devices without an integrated switch, however, require an external Ethernet switch. Users must also connect each individual sensor to the switch using a star topology and then connect this to the control.

The implementation of a linear topology for each integrated switch reduces the cabling requirements, saving time and money.

The familiar control environment

Integrated connectivity also means that you can work in your usual control environment. This is possible because the entire device parametrization is integrated in the GSDML file ("Generic Station Description Markup Language") of PROFINET, for example. In contrast, many other Ethernet-based devices on the market generally have to be parametrized via a web server. This is complex, as every manufacturer supplies their own web server version with its own user interface. Users have to familiarize themselves with new interfaces every time and find the corresponding functions. And another issue: devices without Ethernet that are connected via a gateway frequently need product-specific manufacturer's software for parametrization. This in turn can cause problems regarding compatibility with the hardware used. For example, if the manufacturer no longer updates their software after a number of years. Here too, integrated connectivity has multiple advantages:

- Users stay in their usual control environment

- Installation of manufacturer's software and associated familiarization are not necessary

- Access to a web server is not required

Devices from Leuze that are equipped with integrated connectivity are very easy to parameterize. The GSDML file only has to be downloaded from the Leuze website via the control and copied once into the company's own engineering software. The modules are then available in the hardware catalog. A meaningful description of the device functions is also included. This makes it very easy to parametrize and use a sensor and the manual is not required in most cases.

Simple interface management in all control environments with "integrated connectivity".

Support from the sensor

A look at the device profile of sensors with integrated connectivity illustrates additional ways in which programming is made easier. As an example: for the AMS and BPS positioning sensors, Leuze not only supplies positioning values, but also a calculated speed value. Users who require this value in their system save time as they do not have to carry out their own calculations. What is more: without integrated connectivity, the control must be used to filter for specific bar codes. Leuze BCL bar code readers make this more efficient, as it is possible to prefilter according to specific criteria. Only codes which correspond to the required pattern are transferred to the control. The option to duplicate PROFINET devices in the engineering tool is also a time-saver. Users only have to specify the parameters once and can then copy the settings as needed. Integrated connectivity even helps when a device is exchanged: If a damaged sensor has to be replaced, the system automatically transfers all the parameters stored in the control to the new device. The sensor is ready for use straight away.

The BPS 300i bar code positioning system (on the left in the image) is equipped with integrated connectivity.

The IPS 200i/400i sensors for fine alignment in intralogistics are equipped with integrated connectivity.

Keeping an eye on quality

Integrated connectivity not only provides support during commissioning, but also with machine monitoring (condition monitoring). For efficient operation, system operators need answers to questions such as: is the system running without errors? When do I need to schedule maintenance? The answers are provided by the integrated interface. Via industrial Ethernet communication, it not only transmits the actual process values, but also diagnostic data which are available in the control. As a result, all identifying data can be read out via a bar code reader to manage the device. This includes the serial number or the software/hardware version of the sensor. Moreover, there are quite a number of diagnostic parameters, such as the number of OK and NOK readings. In particular, the system provides a quality marker for each individual code reading in a plant with bar code readers. This provides information on the quality of the readings. The value is generally between 90 and 95 percent and can be monitored to detect deviations during operation, for example caused by contamination or mechanical damage. Remote monitoring can also be implemented as an additional communication channel via OPC UA. The control can be used for this purpose, but Leuze sensors provide a much more comfortable solution, as they can be accessed directly via the OPC UA. As a result, system operators can monitor their devices in parallel to the ongoing process. This gives them real-time information on the performance of the system. If required, these data can also be transferred to a cloud - there are no restrictions whatsoever.

Integrated connectivity offers advantages during commissioning, processes can be optimized, making it possible to achieve optimum system operation.

Simple process optimization

How can processes be optimized on the basis of the collected data? This is demonstrated by two representative practical examples using bar code readers. First example: The scanning window of the sensor can become contaminated. In some systems this does not happen for years, in others it occurs more quickly. Data evaluation via OPC UA can be used to quickly determine which sensor is contaminated. Using the data, a software program records the read quality of each individual decoding process. For bar code readers with impaired reading performance, it indicates that maintenance is required. Second example: The label itself can also cause problems - for example if the code is damaged or printed incompletely. In this case, it is not enough to monitor an individual sensor to determine the error. Instead, the faulty label has to be traced along different measuring stations to identify it. This makes it possible to detect similar evaluations and use the identification number to determine the label involved.

Integrated connectivity for optimum operation of the system

Summary: increased efficiency on three levels

Integrated connectivity offers advantages on several levels. It contributes to easier commissioning and provides additional information for machine monitoring. This information is particularly useful for process optimization, resulting in optimal system performance. All sensors developed by Leuze for fieldbus-controlled automation, for example in intralogistics, are equipped with integrated connectivity. This allows system operators to save time and money.