About Leuze

More than 60 years of experience have made us a real expert in innovative and efficient sensor and safety solutions for automation technology. We, the Sensor People, prompt technological progress and change through passion and determination. This is how we create tomorrow’s innovations and set new standards on the market together with you.

Short profile

Leuze was founded in Owen/Teck in Southern Germany – its headquarters. Today there are more than 1500 Sensor People around the world who are working with determination and passion for progress and transformation to make our customers successful in a constantly changing industry. Regardless of whether in the technological competence centers or in one of the 22 sales companies, supported by more than 40 international distributors.

Product range

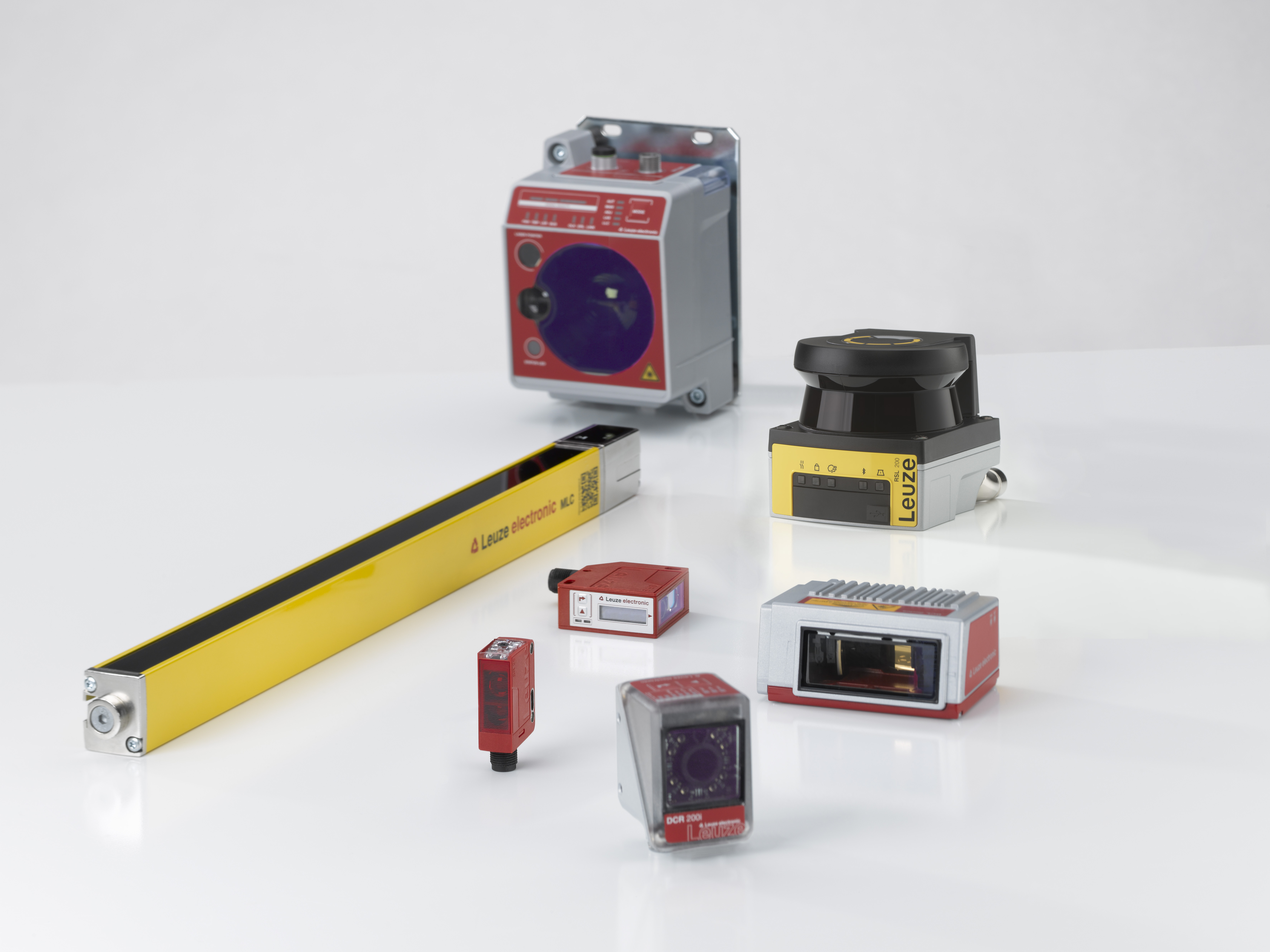

Our high-tech product range includes a number of different sensors for the field of automation technology. For example, switching and measuring sensors, identification systems, solutions for data transmission and image processing. As a Safety Expert, we are also focused on components, services and solutions for safety at work.

We are the Sensor People.

As a medium-sized family business headquartered in Owen/Teck (in the greater Stuttgart area), we actively work to create the future of Industry 4.0 with our products. In this regard, our employees are our most important potential and our greatest pillars.

Find out what makes Leuze as an employer so unique.

Current news

We sell optical and inductive sensors as well as identification, data transmission and image processing systems and components, services and solutions for safety at work.

Our sales company Leuze electronic Deutschland GmbH + Co. KG is located in close proximity to our headquarters in Owen/Teck, Baden-Württemberg. We, the Sensor People, offer expert advice and reliable customer service.

We develop and manufacture optical and inductive sensors as well as identification, data transmission and image processing systems.

As a leading innovator in optical sensors, Leuze was founded in 1963 at its current headquarters in Owen/Teck, Baden-Württemberg. More than 60 years of experience made us Sensor People real experts in innovative and efficient sensor and safety solutions for industrial automation.

Our high-tech product range includes a number of different sensors for the field of automation technology. For example, switching and measuring sensors, identification systems, solutions for data transmission and image processing. As a Safety Expert, we are also focused on components, services and solutions for safety at work. Our main focus is on the areas of intralogistics, packaging industry, machine tools and automotive industry, as well as laboratory automation.

Leuze electronic GmbH + Co. KG

In der Braike 1

73277 Owen

Phone: +49 7021 573-0

Fax: +49 7021 573-199

E-mail: info@leuze.com

We develop safety at Leuze. And by that we mean more than just safety components.

This also includes safety services and turnkey safety solutions for safety at work. Our objective is to make your machines and systems even more efficient and safer at the same time. After all, your success is our motivation. As a safety expert, we have decades of expertise in this area and have already pioneered numerous safety innovations: from the very first protective sensor to the invention of the AS-Interface. The first safety laser scanner with PROFIBUS connection is also our brainchild. So is Smart Process Gating, which offers sensorless muting for space-saving access guarding on conveyor lines. Our safety consultants develop comprehensive safety concepts and accompany you through the entire project including the safety acceptance.

Leuze electronic GmbH + Co. KG

Industriestraße 17

82110 Germering

Phone: +49 7021 573-0

Fax: +49 7021 573-199

E-mail: info@leuze.com

We develop, manufacture and sell electronic assemblies and assembled printed circuit boards as well as integrated systems built on the PCBs, both for the Leuze electronic group and for external customers. We offer highly innovative solutions, a good price/performance ratio and our individual, customer-specific support.

A sophisticated logistics concept enables us to combine a wide range of batch sizes with a high degree of variety. Our extensive portfolio of technological services makes us a competent and reliable partner for the assembly of THT and SMT components on flexible or rigid PCBs. Our area of specialization is connection technology on flexible base material and the assembly of fine pitch BGAs, including package-on-package (PoP) solutions. State-of-the-art testing technologies, such as Flying Probe and AOI for optical process inspections, ensure our high quality standards.

Leuze electronic assembly GmbH

Stützenstraße 3

89619 Unterstadion

Phone: +49 7393 9508-0

Fax: +49 7393 9508-49

E-mail: assembly@leuze.de

www.leuze-electronic-assembly.de

Memberships