Hydraulic press brake

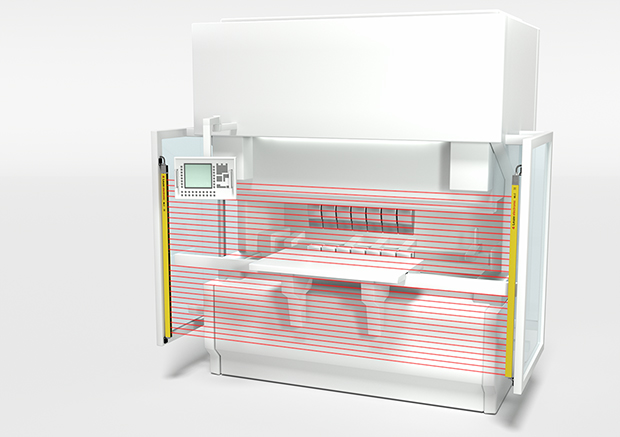

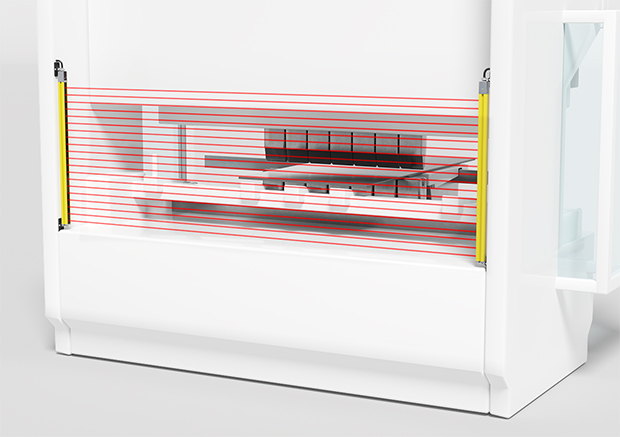

In hydraulic press brakes, bending presses or bending machines, a wide range of sheet metal parts are produced through bending. Extreme forces are at play here in some cases. These as well as the large dimensions of the manufactured parts require various safety measures.

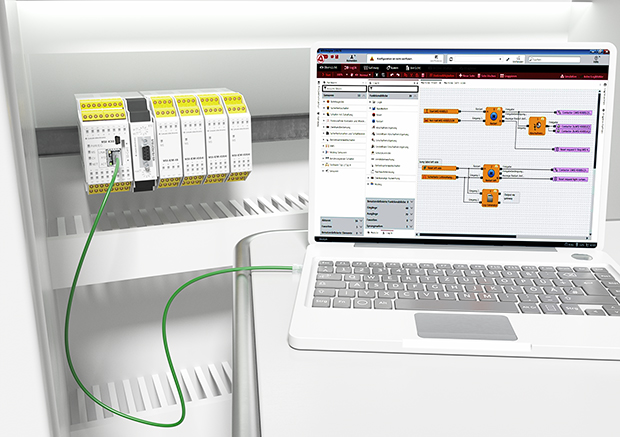

Our robust safety light curtains safeguard points of operation as needed. The series includes many different models. It thus offers a perfect solution for nearly every requirement. Flexible blanking functions also make it possible to adapt to different work pieces and make them safe, yet efficient to use.