Power PinPoint® LED

To the point: New sensors with Power PinPoint® LED

The light spot makes all the difference: small, bright and precise

The diffuse sensors and photoelectric sensors with Power PinPoint® LED use innovative light source technology. Thanks to the newly developed light-emitting diode, the sensors’ optical system generates a light spot that retains its size, shape and homogeneity throughout the sensor’s entire working range.

Advantages for you

- Easy commissioning of sensors for object detection through small, round, homogeneous light spot across the sensor’s entire working range

- Perfect object tracking with precise start and end detection of the object with pinpoint response behavior

- Diffuse sensors detect small objects particularly reliably due to their optimal response behavior and high level of precision. Sensors with Power PinPoint® LEDs can also be used instead of laser diffuse sensors in some applications.

- Better detection results in applications with small reflectors and long distances due to higher functional reserves in retro-reflective photoelectric sensors

- Higher detection reliability for throughbeam photoelectric sensors in parallel operation of several sensors thanks to the compact light beam with low divergence and improved diffused light suppression

- With throughbeam photoelectric sensors, reflection bypasses are minimized

Highlights

Easy and fast sensor commissioning

Commissioning sensors can be expensive and time-consuming, especially if many sensors have to be installed in a system. The small, bright and homogeneous Power PinPoint® light spot exactly reproduces the sensor’s response behavior. This makes the alignment of the sensors particularly easy and intuitive.

Why is the light spot so visible? The new LED is optimized in such a way that it emits the maximum light power from a very small surface. This results in a bright light spot with sharply defined contours.

Precise detection results and high process reliability

Sensors with Power PinPoint® LED enable very precise detection results. They offer notable advantages in specific applications, depending on the operating principle:

The Power PinPoint® light-emitting diode ensures improved response behavior, a high level of precision and reliable detection of small objects for diffuse sensors. Retro-reflective photoelectric sensors achieve a higher function reserve, especially with small reflectors. Throughbeam photoelectric sensors with the new LED technology, increase detection reliability by minimizing diffused light and reflection bypasses. Small light spots with low divergence and optimized diffused light emission make parallel operation of multiple sensors easier.

Application

Compartment fine positioning with diffuse sensors

Requirement:

After the stacker crane has been roughly positioned, the compartment fine positioning should take place. For this, the bar and column edges should be optically sensed at a distance of 100 to 600 mm.

Solution:

Diffuse reflection sensors ensure the load receptacle is positioned correctly. A wide range of profile types as well as color or glossy surfaces are reliably detected. Diffuse sensors with background suppression have an optimal response behavior and a high level of precision when sensing the edge of a column thanks to the defined and homogeneous Power PinPoint® light spot.

Detection of boxes in conveyor systems with retro-reflective photoelectric sensors

Requirement:

In packaging processes, products are transported between different process steps in standardized containers. To protect the unpackaged food, systems and their components must withstand regular intensive cleaning processes.

Solution:

Retro-reflective photoelectric sensors achieve a higher function reserve with Power PinPoint® LEDs, especially with small reflectors. This is particularly advantageous for space-critical applications. Furthermore, commissioning and alignment with the reflector is completed in no time at all.

Presence control of battery cells with throughbeam photoelectric sensors

Requirement:

Before the liquid is injected at the filling station, it is necessary to check that the battery cells are in the correct positions. This is also required to ensure that the battery cells are gripped reliably.

Solution:

Throughbeam photoelectric sensors with the new Power PinPoint® LED technology reliably detect the battery cells even in confined spaces. The Power PinPoint® LED increases detection reliability by minimizing diffused light and reflection bypasses. The compact light beam with low divergence and optimized diffused light emission enables easier parallel operation of several sensors, even when many throughbeam photoelectric sensors are mounted in parallel.

Optical sensors with Power PinPoint® LED

Power PinPoint® LED technology is used in our optical sensors for object detection. Diffuse sensors are currently available in the 25C, 3C and 5B series.

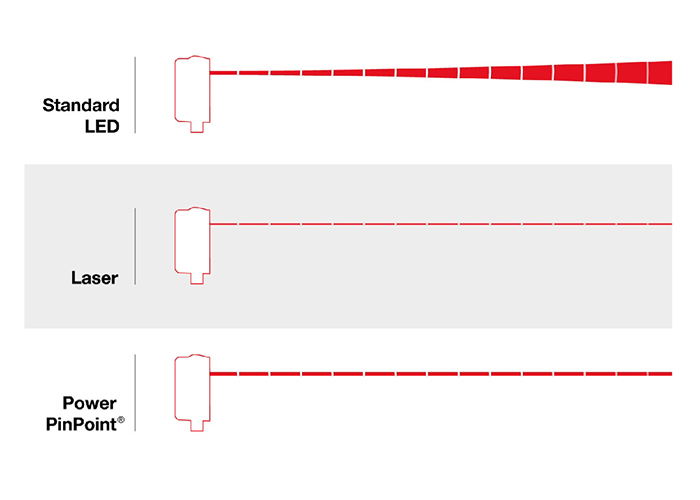

The right light source technology for every application

At Leuze, you can find the sensor with the right light source technology for every detection task. You achieve reliable detection results if the light spot produces the optimum response behavior for detecting the given object.