Contrast sensors

Advantages for you

- Flexible thanks to multiple types of light in a single housing: multicolor (red, green or blue light), white light and laser-generated red light

- Reliable detection of even the slightest contrast differences and of print marks even on glossy and highly reflective materials

- Highly precise and reliable identification of contrasts with a short response time of 50 µs (laser: 125 µs) and minimal signal jitter for optimum machine throughput

- High mounting flexibility and easy integration even in tight installation spaces due to a compact and robust housing with a high degree of protection of IP 67 and IP 69K as well as ECOLAB certification

- Multiple teach modes are available for selection, thereby ensuring the appropriate adjustment routine for easy and fast machine commissioning (static or dynamic 2-point teach, static 1-point teach)

- IO-Link for easy integration of additional functions into the machine control, for example easy format changeover due to recipe management, parameterization of the sensor, or locking of the teach button to prevent tampering

Highlights

Three light types in a compact housing

Every application has different requirements on the sensor system with respect to reliable contrast marker detection. Because the emitted light color determines the reliability with which contrast markers are detected, the new KRT 3C contrast sensors use three different light types. This allows customers to select the appropriate light source for each type of material and for each contrast marker color in packaging or labeling processes.

- Multicolor uses red, green or blue LED light (RGB). Through the automatic selection of the right transmitter color, various color or gray value combinations can be reliably detected. Multicolor devices are especially well suited for very colorfully printed films.

- The white light LED is used if it is necessary to distinguish colors and gray values from a reference gray value (with equal contrast resolution). This provides greater reliability particularly in the case of contrast markers on glossy surfaces.

- Contrast sensors with a red light laser emit a very small laser light spot and are therefore the ideal choice for detecting very small markers and changes in distance.

Easy configuration and recipe management due to IO-Link

The new KRT 3C contrast sensors are adjusted either via a teach button, remotely by teaching via a cable or – conveniently – via IO-Link. Using IO-Link, sensors can easily be integrated in an automation system. This type of automation simplifies integration and thereby helps keep downtime in production to an absolute minimum. The new compact contrast sensors can be configured, operated and maintained (condition monitoring) via IO-Link.

- Convenient format changeover to a different film or label type by uploading the respective parameter set including teach value to the contrast sensor (also possible directly via the Human Machine Interface (HMI))

- No setup time and no re-teaching of the contrast sensor when changing format

- Real-time signal information and diagnosis

- Quick and easy remote teaching or locking of the teach button via IO-Link interface

- The variety of teach modes enables fast commissioning of the machine:

- Static 2-point teach: Suitable for manually positioning markers and background

- Dynamic 2-point teach: Suitable for moving markers within automated machine processes

- Static 1-point teach: Suitable for detecting any type of markers against a homogeneous background or outside of a reference value

High mounting flexibility due to a robust miniature housing

The requirements placed on sensor systems are high in packaging processes: Objects or cut marks must be detected quickly and with high switching reliability. In addition, there are also challenging environmental conditions such as tight installation spaces or frequent cleaning processes. The new KRT 3C contrast sensors have a robust miniature housing and can be used flexibly for various detection tasks.

- The small construction, just 32 mm in height, ensures flexibility during mounting, especially in confined spaces

- This product can also be used in areas requiring degrees of protection IP 67 and IP 69K

- The ECOLAB certification ensures that the sensors are also suitable for applications where the system is cleaned regularly and cleaning agents are used

Application

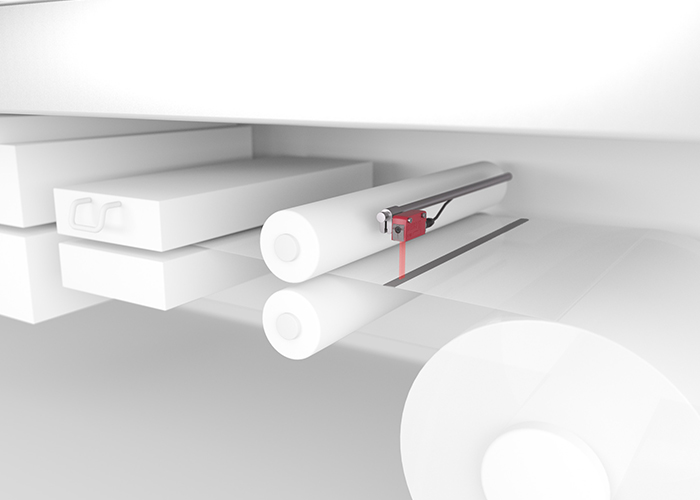

Detecting cut marks on the film feed

Requirement:

In the packaging industry, products are packaged into tubular bags on horizontal packaging machines. Contrast sensors detect the printed contrast markers and precisely determine when the packaging film is cut. Common challenges are the limited installation space and the frequent format changeovers with films and contrast markers of different colors.

Solution:

The compact KRT 3C contrast sensor combines three light types in a single housing: RGB, white light and laser-generated red light. During the packaging process, production planners are thereby able to respond very flexibly to materials with different color or gray value combinations. To prevent system downtime, all settings can be adjusted via the IO-Link interface, even during format changes.

Tube alignment in a filling system through color mark detection

Requirement:

In a tube filling and sealing machine, tubes are filled with hand cream. During the packaging process, it is important that the plastic tubes are aligned precisely after filling so that the tube fold is pressed in exactly the right place. In many tube fillers, there are also confined spaces.

Solution:

Due to its compact size and small dimensions, the new KRT 3C contrast sensor saves a lot of space during mounting. It reliably and highly precisely detects contrast markers of different colors even on round objects and different materials, with a short response time of just 50 µs.

The film feed in thermoforming machines

Requirement:

Thermoformed tray packaging is frequently used in the food and pharmaceutical industries. An endless plastic film is fed into a thermoforming machine. The challenge is how to detect the end of the film early so that production interruptions to the packaging process can be kept as short as possible.

Solution:

The new KRT 3C contrast sensor reliably detects the splice on the film underneath that indicates the end of the film roll. In this way, the sensors ensure that processes are stable and involve little downtime.

An overview of our contrast sensors

We offer a wide selection of contrast sensors to ensure that we can offer just the right solution for each of our customer' detection tasks. While the new KRT 3C contrast sensor is characterized by its small, robust housing and variants with laser light source, the KRT 18B contrast sensor scores with its permanent signal display with a bar graph and automatic sensitivity readjustment. The KRT 55 makes an extremely strong impression with its stainless steel housing; the KRT 20, with a response time of just 10 µs is our fastest contrast sensor. The KRT 21, on the other hand, is an all-rounder for many applications.

| Feature | KRT 3C | ||||

|

| | ||||

| Dimensions without connector (WxHxD) | 11 x 32 x 17 mm | 14 x 35.5 x 25 mm | 15 x 47 x 32.5 mm | 30 x 53 x 80 mm | 31 x 53 x 80 mm |

| Operating voltage | 12 – 30 V DC | 10 – 30 V DC | 10 – 30 V DC | 12 – 30 V DC | 10 – 30 V DC |

| Outputs | Push-pull, PNP, NPN, IO-Link | PNP | Push-pull, analog, IO-Link | PNP, NPN, analog current | PNP, NPN |

| Connection type | M8, cable, cable+M12 | M8, cable+M12, cable | M12 | M12 | M12 |

| Degree of protection | IP 67, IP 69K | IP 67, IP 69K | IP 67, IP 69K | IP 67, IP 69K | IP67 |

| Operating range | 14.5mm ± 2 mm | 13mm ± 2 mm | 13mm ± 3 mm | 13mm ± 1 mm | 9mm ± 3 mm |

| Light source | LED, laser (class 1) | LED | LED | LED | LED |

| Switching frequency | 4,000-10,000 Hz | 10,000 Hz | 15,000-22,000 Hz | 16,000 Hz | 15,000 Hz |

| Transmitter color | RGB / white / red laser | RGB / white | RGB / white | RGB | RGB |

| Light beam gate | Front | Front | Front | Lateral or frontal | Lateral or frontal |

| Light spot shape | Rectangular or round | Rectangular | Rectangular | Rectangular | Rectangular |

| Light spot orientation | Lengthwise / sideways | Vertical | Lengthwise / sideways | Vertical | Vertical |

| Operation | Teach button, cable, IO-Link | Teach button, cable | Multiturn potentiometer, buttons, teach button, IO-Link | Membrane keyboard, via cable | Teach button |

Advantages for you

- Models in multicolor (RGB) or white light (W) offer optimum performance for marker detection on colorfully printed or glossy films

- White light provides greater reliability in the case of contrast markers on glossy surfaces

- Multicolor (RGB) provides better performance with colorfully printed films

- Free selection of adjustment method: intuitively using removable potentiometers, quickly and precisely by means of teach buttons. Also of course remotely through teach via cable or IO-Link

- IO-Link with dual channel: for monitoring, diagnosis, easy changeover in the case of format change

- Three teach levels ensure the perfect adjustment routine for every application

- Static 2-point teach with stationary conveyor belt based on marker and background

- Dynamic 2-point teach with running conveyor belt

- Static 1-point teach detects any contrast markers in front of a homogeneous background

- Permanent signal indication through self-adjusting bar graph on the rear side of the sensor

- Tracking function with threshold tracking for fading contrast markers

- Fine adjustment of the switching threshold through "near-to-marker" teach or EasyTune (T)

- Light spot variants with horizontal or vertical alignment

- Flexible operating range of 13 mm +- 3 mm

- Maximum switching frequencies up to 22 kHz / response time 20 µs

- Small, compact housing made of nickel-plated metal, IP67 and IP69K and ECOLAB

Highlights

Twice as much choice: Contrast sensors in white light and RGB

Depending on the packaging characteristics, white light or RGB may be of advantage for contrast detection. In order to provide our customers with full flexibility in the choice of their contrast sensor solution, we are doubling our KRT 18B product range and extending our innovative series by adding an intelligent 1-point teach to our white-light models. In addition to the high degrees of protection IP67 and IP69K, the extremely small and elegant housing also has ECOLAB certification for use in harsh environments. This ensures that our contrast sensors also withstand intensive cleaning cycles without problem.

IO-Link inside

The KRT 18B series contrast sensors feature an innovative, dual operating concept: Depending on the customer preference, all sensor functions can be configured via IO-Link or a simple, manual sensitivity adjustment can be carried out via potentiometer or teach button.

IO-Link can be used to implement innovative machine concepts with remote maintenance, diagnosis or sensor configuration.

Three different teach processes via IO-Link

Each application requires a different adjustment routine for the sensor. Easy to adjust via teach button, remotely via cable or IO-Link:

- Static 2-point teach: With the conveyor belt stationary, the sensor is taught to the marker and then to the background – or vice versa. The switching threshold is set between the two signal values and can be set closer to the marker by means of a subsequent teach.

- Dynamic 2-point teach: With the conveyor belt running, a measurement window is opened by pressing the teach button. As soon as multiple markers have passed under the sensor, the window is closed by pressing the teach button again. Here too, the switching threshold can be set closer to the marker by means of a subsequent teach.

- Static 1-point teach: With the conveyor belt stationary, the sensor is aligned with the background and then taught to it. Each marker that deviates from this signal is detected as a contrast marker. The switching threshold can be moved by performing the teach again.

Application

Cut mark detection on packaging film in the film feed

Requirement:

A product is wrapped in a horizontal form-fill-seal (FFS) system. The packaging film must be cut to the exact size. The feed rate of the packaging film is controlled through the detection of contrast markers, which can have different colors and in some cases differ only slightly from the print on the film.

Solution:

The new KRT 18BW contrast sensor in the white-light version reliably detects contrast markers in a wide variety of colors, even on a glossy background. Here, the dynamic 2-point teach offers the possibility of configuring the sensor even while the film is moving. Fading print marks, e.g. towards the end of the film roll, can be compensated by the tracking function.

Color mark detection for tube alignment in a filling system

Requirement:

In a packaging system, plastic tubes are filled with toothpaste. The tubes must be correctly aligned before the fold is made at the end of the tube. The distance from the object to the sensor can vary by a few millimeters when the tube is rotated.

Solution:

The KRT 18BW also operates reliably even if the operating range relative to the object changes by 20%. With a homogeneous background, the white-light model also detects differently colored contrast markers, which saves time and effort particularly in the case of a format change.

Technical properties

| Feature | KRT 18B Standard | KRT 18B Teach | KRT 18B Multiturn | KRT 18B Tracking | KRT 18B Speed | KRT 18B Analog |

| Setting | Teach-in | Teach-in | Spindle | Teach-in | Teach-in | Spindle |

| Bar graph | No | Yes | Yes | Yes | Yes | Yes |

| Light source | RGB (red/green/blue) White light | RGB (red/green/blue) White light | RGB (red/green/blue) White light | RGB (red/green/blue) White light | RGB (red/green/blue) White light | RGB (red/green/blue) |

| Switching frequency | 15 kHz | 15 kHz | 15 kHz | 15 kHz | 22 kHz | 15 kHz |

| Response time | 33 µs | 33 µs | 33 µs | 33 µs | 22.5 µs | 100 μs |

| IO-Link version | No | Yes | No | Yes | Yes | No |

| Operating range | 13 ± 3 mm | 13 ± 3 mm | 13 ± 3 mm | 13 ± 3 mm | 13 ± 3 mm | 13 ± 3 mm |

| Switching output | PNP, NPN | Push-pull (IO-Link) | Push-pull (IO-Link) | Push-pull (IO-Link) | ||

| IO-Link | - | V1.1 (COM2) | V1.1 (COM2) | V1.1 (COM2) | ||

| Operation | 2 potentiometers:

| 2 potentiometers:

| 2 potentiometers:

| 2 potentiometers:

| ||

| Degree of protection | IP 67 | IP 67 | IP 67 | IP 67 | ||

| Certifications | CE, UL | CE, UL | CE, UL, ECOLAB | CE, UL, ECOLAB | ||

| Connection | M12 4-pin | M12 4-pin | M12 4-pin | M12 4-pin | M12 4-pin | M12 4-pin |

| Temperature range | –40 to +60 °C | –40 to +60 °C | –40 to +60 °C | –40 to +60 °C | –40 to +60 °C | –40 to +60 °C |