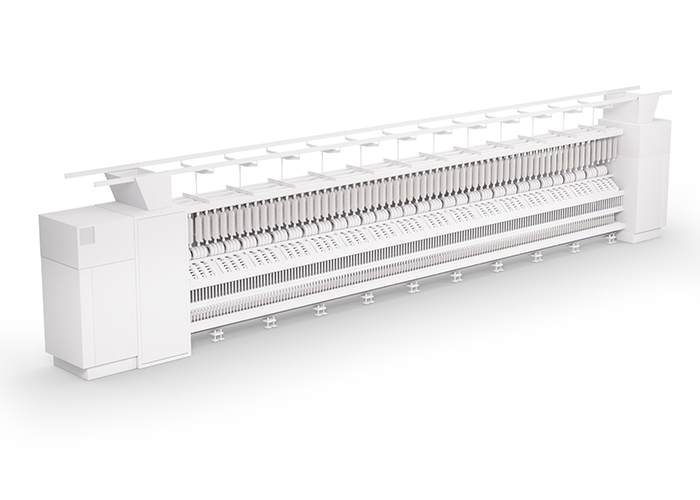

Sensor solutions for ring frame machines

Automated winding and drawing processes are designed to improve roving stability and uniformity. This step ensures that the yarn meets the quality standards required for subsequent textile production. The process parameters are adjusted depending on the end product to provide high-quality yarn with the required strength, uniformity, and length.

Bobbin detection in the feeder

Requirement:

For automatic filling of empty bobbins, every bobbin must be reliably detected, regardless of color and surface structure. Feeding takes place from both ends of the machine, and the solution must be compact and easy to integrate into existing machine designs.

Solution:

A miniature optical throughbeam photoelectric sensor, e.g. LS/LE 3C, is installed transversely on the machine head at the feeder. It reliably detects every bobbin, regardless of material, color or structure. The sensor also allows the number of transported bobbins to be monitored. Its compact design facilitates space-saving integration into the machine setup and supports automated, error-free filling.

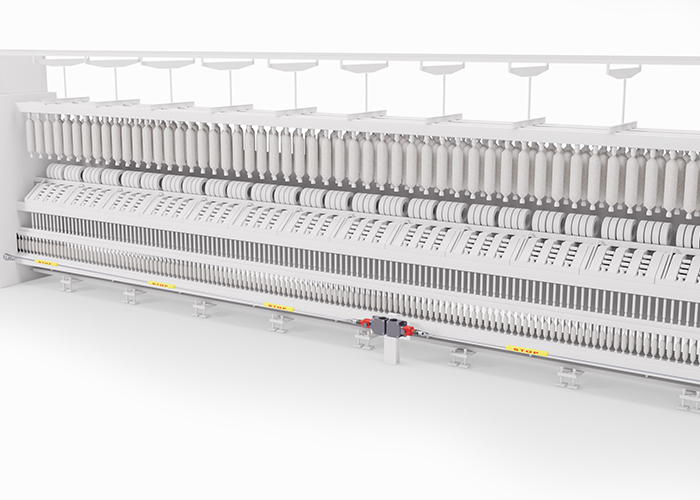

Removal check

Requirement:

At the end of the process, several bobbins are simultaneously filled at the next yarn-refining step. As removal is also automated, the empty state of all bobbin positions must be reliably checked before they are reloaded to avoid incorrect filling or collisions.

Solution:

A throughbeam photoelectric sensor for long operating ranges, e.g. LE/LS 46C, is suitable for monitoring as it can detect the empty state of the bobbin positions across the entire width of the machine. Automatic refilling is only started after confirmation that all positions are free. The solution ensures reliable, continuous process control and prevents downtimes and material losses.

Emergency shutdown

Requirement:

In the event of serious malfunctions in machine operation or in the production process, operating personnel must be able to stop the machine safely regardless of its position. The solution must ensure a fast, reliable emergency shutdown and meet safety requirements.

Solution:

The machine dimensions make ERS safety rope switches a suitable option, which can be installed on both of the machine’s long sides. If necessary, an emergency stop can be triggered by pulling at any point on the rope. The signals from the rope switches are routed to safety relays that control the entire machine shutdown. This solution provides a flexible, position-independent emergency stop function and meets all relevant safety requirements.