Multi-station access guarding in forklift truck logistics

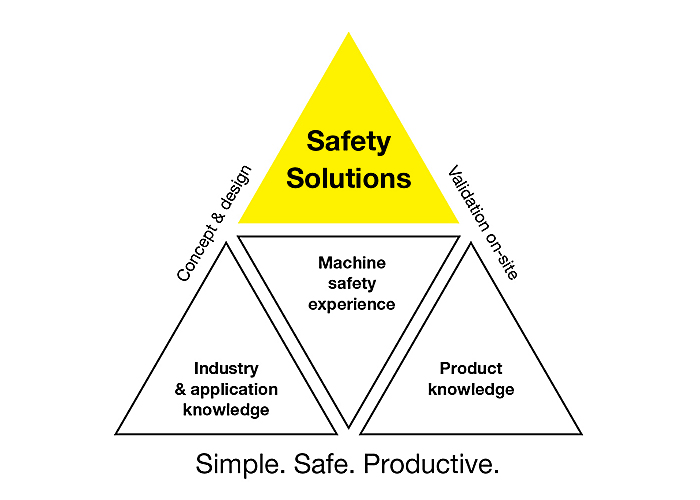

From risk assessment to validation: our safety solutions provide complete solutions for your systems. Our expert teams’ innovative safety concepts ensure efficient material flow, gapless safety and high availability of your system. Even in applications where classic concepts are pushed to their limits. Always with legal certainty, CE certification and compliance with standards.This makes deploying them extremely easy for you.

When corridor supply vehicles, such as forklift trucks, are working at a transfer station to a danger zone, it is important that access guarding can reliably differentiate between a forklift truck and personnel. Common safety concepts often have limited options and require significant structural or procedural changes to ensure safe operation. In practice, this may result in compromises with correspondingly high residual risks, as well as a high degree of individual responsibility and discipline on behalf of the instructed operating personnel. For example, safety gaps may occur next to the forklift truck during transfer, the system may need to be operated at reduced speed during approach, or the system may need to be shut down entirely during the transfer.

Our safety solution for multi-station access guarding in forklift truck logistics is designed for exactly these types of applications. It ensures gapless safety and at the same time guarantees a high degree of utilization of the system thanks to optimized processes.

Requirement:

A cross conveyor has several transfer stations at which forklift trucks carry materials in and out. The entire transfer area must be secured against unauthorized access. When a forklift truck approaches, the relevant station must be released for access.

Solution:

Safety laser scanners with a vertically aligned protective field secure the access point. At each station, additional sensors monitor the movement of the forklift trucks and send this information to the safety system.

The safety system adjusts the protective field accordingly for access into the station. The entire process is monitored for safety.

Operating principle:

The vertical protective field is installed in front of the danger zone. Each station is additionally monitored with monitoring sensors. The safety system only releases a defined area in the protective field for the exact station that the forklift truck is approaching. All other stations remain secured by the protective field. As soon as the forklift truck has left the transfer area, the protective field is reset to its original state. The forklift trucks can enter and leave the area without interrupting operation, and all stations can be used simultaneously and independently of each other.

Advantages for you

- Save time and money with our pre-developed and process-optimized safety solutions

- Continuous monitoring of the entire transfer area

with reliable differentiation between forklift trucks and operating personnel - Scalable to the number of stations in your system

- Reliable separation of the traffic and transfer areas enables further optimization of individual work procedures

- High reliability and availability

- Optimum protection against tampering

System components and safety parameters

| Safety sensor: RSL 400 safety laser scanner | |

| Monitoring sensors: Ultrasonic and radar sensors | |

| System control: Siemens SIMATIC S7 | |

| Leuze safety program | |

| PL d in accordance with ISO 13849-1, SILCL 2 in accordance with IEC 62061 | |

| 2-channel safety output |