Cold, clever, convenient.

Früchte Jork is putting a new deep-freeze warehouse into operation

Früchte Jork GmbH from Baden-Württemberg, Germany – a family-run fresh food wholesaler – has reached an important milestone: Its new, fully automated deep-freeze warehouse is in operation. What may look like ‘just’ another high-bay warehouse to outsiders is a quantum leap for the company: faster order picking, optimized processes and significantly improved working conditions for employees. The project was implemented by the intralogistics experts at Klinkhammer Intralogistics GmbH.

Why the new warehouse was necessary

As one of the leading food wholesalers in the region, Früchte Jork supplies over 13,000 items to around 600 restaurants and hotels within a radius of 180 kilometers. The company’s steady growth brought the previous manual deep-freeze warehouse, in which order picking was carried out with forklifts at minus 22 degrees, to its limits. Together with Klinkhammer, the owner family therefore developed a concept that takes storage capacity, picking performance, and energy efficiency to the next level. “In recent years, we have evolved from a traditional fruit and vegetable wholesaler to a fresh produce service provider. The automated logistics center is another milestone in our growth strategy,” says Maximilian Jork, Managing Director of Früchte Jork GmbH.

Five lanes at full power

The new, automated deep-freeze warehouse has 26,280 tray storage positions. The goods are stored efficiently in terms of both space and energy – and leave the warehouse just as automatically as they came in. Goods-to-person picking delivers the trays directly to the workstation at an ergonomic height. This means less bending, less lifting, and less time in the frosty storage area.

Smart technology for perfect processes

An integrated sequence buffer ensures that orders are processed in exactly the right order. Flexible tray systems allow various sizes of cartons to be stored. State-of-the-art stacker cranes with camera technology ensure precise control and reduce energy consumption by recovering power during braking. The result: greater precision, shorter distances and reduced electricity consumption.

Precise and safe – even at minus 30 degrees

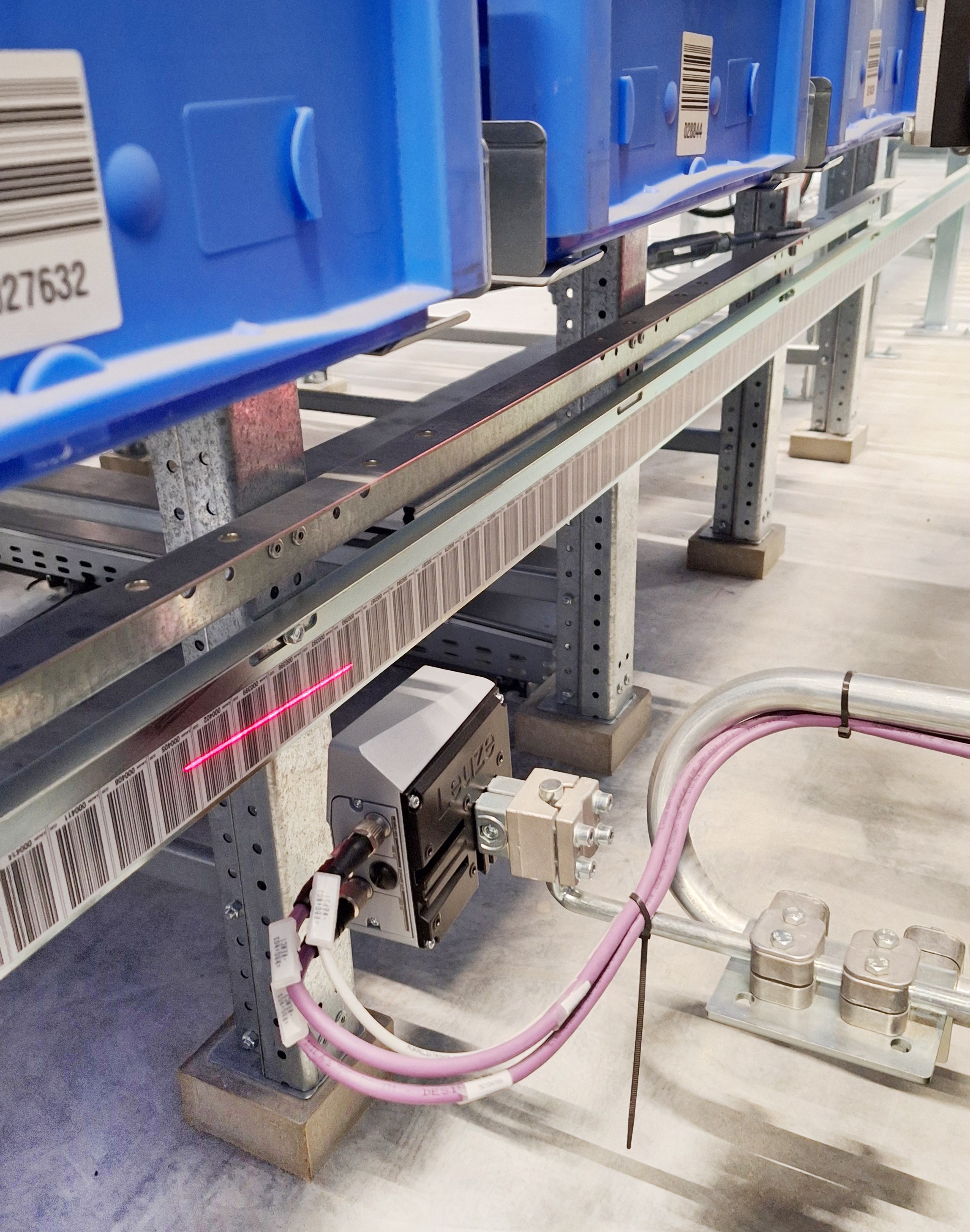

The Leuze FBPS 607i bar code positioning system increases efficiency and reduces costs in automated warehouse operations. Klinkhammer has been using the FBPS 607i from Leuze for positioning its stacker cranes since 2022. The first safe bar code positioning system with redundant SSI interface and integrated heating enables use even at temperatures as low as -30°C. Connected directly to the drive’s frequency converter, the system reacts in just 10 milliseconds. At the same time, the FBPS meets the stricter requirements of the new machinery directive: where two separate devices were once needed to achieve the required performance level, today a single FBPS does the job. This saves time during installation and integration and also makes the solution economically attractive.

Further expansion

The new deep-freeze warehouse is just the beginning. In the second expansion phase, automatic shuttle warehouses for chilled and dry goods were put into operation, which automatically combine orders. This makes the entire logistics process even more efficient. With this investment, Früchte Jork is not only boosting its competitiveness but also making a clear statement: Modern automation can increase productivity and save energy – all while ensuring better working conditions.

Technical features | |

Safety | Safety PL e, SIL 3, category 4 |

Error response time | 10 – 400 ms (adjustable) |

Connection | 2x SSI interface: 2x M12 connector |

Reproducibility | +/- 0.15 mm (1 sigma) |

Reading distance | 50 – 170 mm |

Protection class | IP 65 |

Temperature range | -5 – +60°C |

Dimensions, W x H x D | Connections on the side: 116.3 x 112.5 x 51.5 mm |

Display (optional) | Display of position and status information |

Status signal of reading quality | For early detection of soiling |