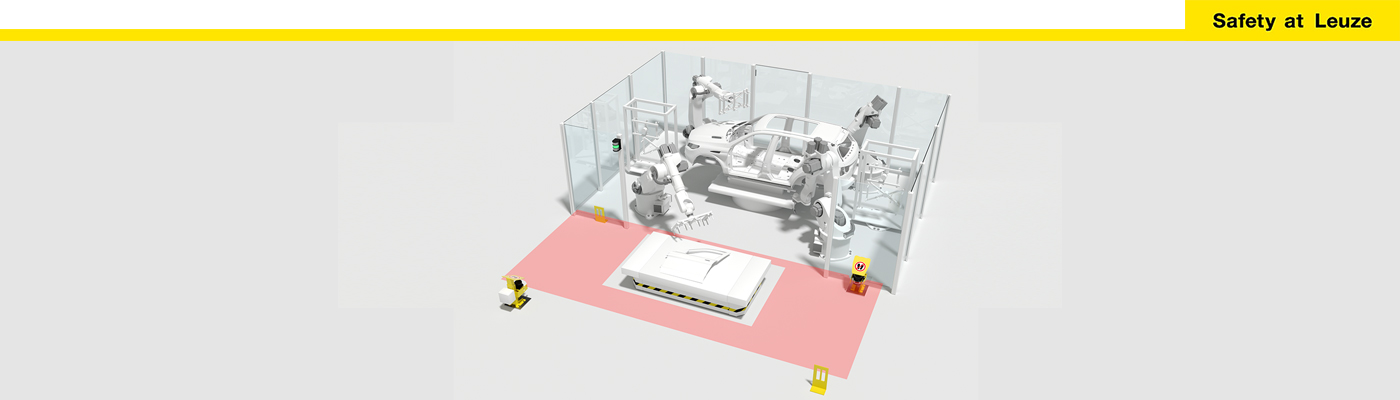

Robot/AGV transfer station safeguarding

Requirement:

The hazardous area of the robot and the working range of the transfer station must be safeguarded against entry by persons during the entire process. The vehicle must be able to enter and exit the working range fully automatically.

Solution:

The entire area of the transfer station is safeguarded with safety laser scanners. Their protective fields detect the entry and presence of persons. When an AGV passes through, its outline is dynamically hidden from the protective fields. This means that the station is perfectly safe at all times.

Operating principle:

The safety laser scanners safeguard access to the robot cell through their protective fields. At the same time, they detect the position of the AGV in the monitoring area. The safety solution uses this information to blank out the outline of the AGV by changing over the protective fields from the monitored area. The AGV is practically “enclosed” by the protective fields. This allows the AGV to automatically move into the station, transfer the material at the parking position and then exit the station again. The safety level is maintained during the entire cycle.

Advantages for you

- Monitoring for the entry and presence of persons

- Gapless safety during the entire cycle

- No restrictions during parts transfer, e.g., for parts that protrude at the front or side

- Autonomous system, simple safety integration

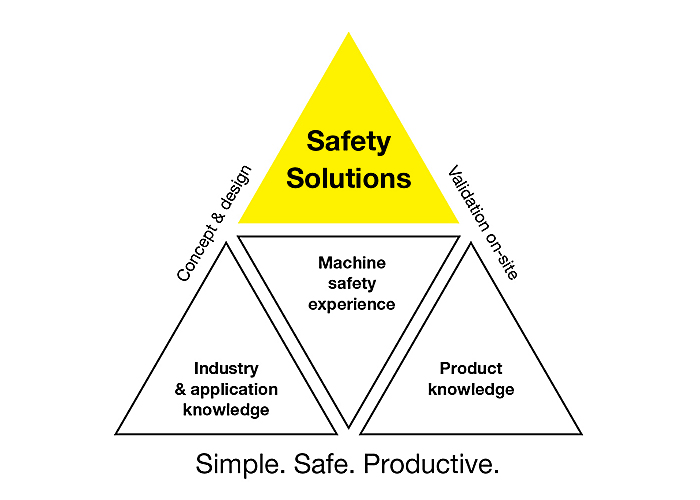

- The pre-designed safety solution is individually tailored to your application

System components and safety parameters

|

Safety sensors: RSL 400 safety laser scanner |

|

| System control: Siemens SIMATIC S7 | |

| Leuze safety program | |

|

PL d in accordance with EN ISO 13849-1, SILCL 2 in accordance with IEC 62061 |

|

| 2-channel safety output |