Guarding of feed points on printing and paper processing machines

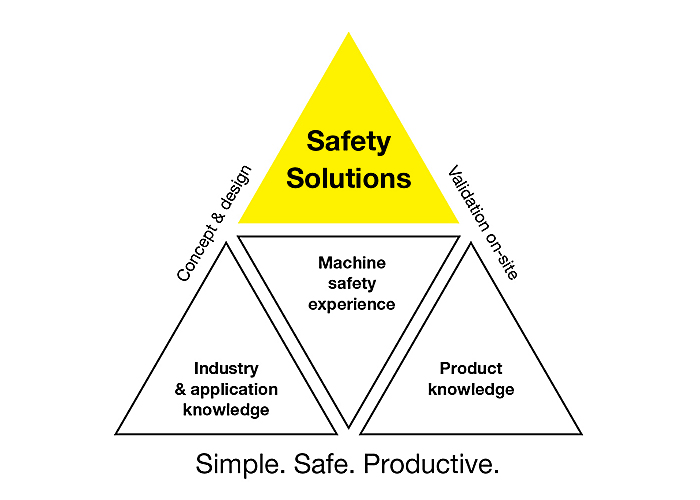

From risk assessment to validation: our safety solutions provide complete solutions for your systems. The innovative safety concepts of our expert teams ensure efficient material flow, gapless safety and high availability of your system. Even in applications where classic concepts are pushed to their limits. Always with legal certainty, CE certification and compliance with standards. This makes deploying them extremely easy for you.

Printing machines, such as those for offset printing, often have separate printing units for each color. The printing units, which are arranged in rows, move apart when manually inserting the printing plates or cloths. The manual equipping and setup process takes place right at the feed point of the rollers and requires the operating personnel to pay very close attention. And even when the machine is used in inching mode, injuries to the hands and crushing of the fingers and hands occur time and again.

Our safety solution for supplemental safety at the feed points of printing machines is designed exactly for these types of applications. It detects the fingers and hands of the operators at the feed points with minimal installation effort. This reduces the inherent risk of this type of setup and significantly increases the safety of the operating personnel.

Requirement:

The printing plates and blankets must be inserted manually during setup mode. The rollers are controlled in inching mode by the operator, such as by using a foot switch. In addition to the selected operating mode, the feed point must be secured against access by fingers/hands.

Solution:

A photoelectric sensor is installed right before the feed point (danger zone), which is connected to a safety system. If the photoelectric sensor detects fingers or hands nearing the danger zone, the dangerous movement is reliably stopped by the safety system. The actual work process remains the same.

Operating principle:

The safety function is active in inching mode. The horizontal light beam of the photoelectric sensor is installed in front of the rollers’ danger zone so that the machine can be equipped and set up, but if a finger or hand comes too close to the danger zone, the light beam is interrupted. As soon as the light beam is interrupted, the safety system switches off the dangerous movement. As soon as the light beam is clear again, movement can continue in inching mode.

Advantages for you

- You save time and money with our pre-developed and

process-optimized safety solutions - Safe monitoring of the feed area of printing machines

avoids dangers when inserting - Gapless safety during the insertion process

- High reliability and availability

- Easily retrofittable

System components and safety parameters

| Sensor: Throughbeam photoelectric sensor series 3C | |

| Evaluation unit: MSI-TR1B safety relays | |

| PL c in accordance with ISO 13849-1, SILCL 1 in accordance with IEC 62061 | |

| 2-channel safety output |