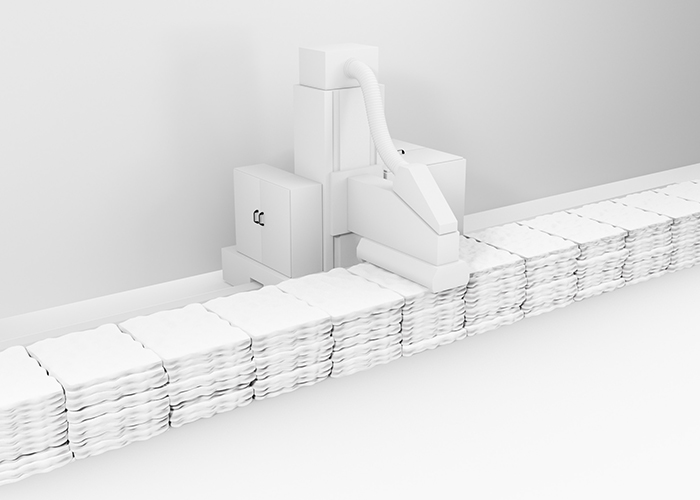

Sensor solutions for bale-picking machines

In this process step, the cleaned and dried raw material (e.g., cotton fibers) is picked up by the machine and fed to the first processing stage.

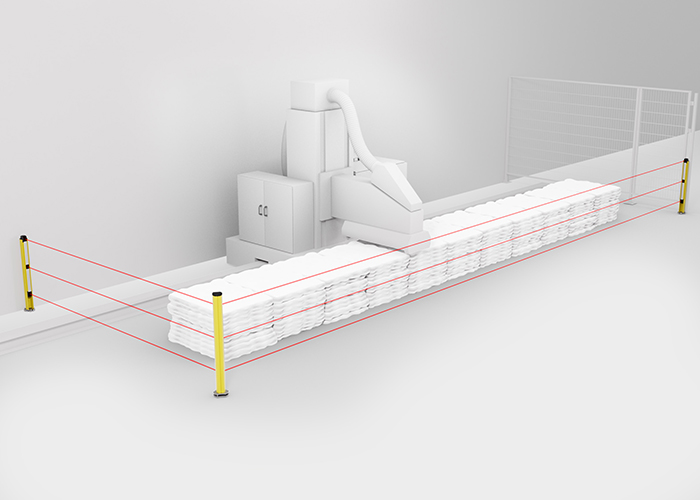

Area safeguarding

Requirement:

When operating the bale picker, the corresponding working range must be continuously monitored to ensure that it is free of people or obstacles. At the same time, direct integration with the machine control system is required to automatically initiate safety-relevant measures.

Solution:

Use of an MLD 500 multiple light beam safety device with a long operating range, supplemented by a deflecting mirror to cover large areas. The safety sensors are mounted in robust UDC-type device columns, which protect the sensor technology as well as facilitate the precise alignment of the photoelectric sensors.

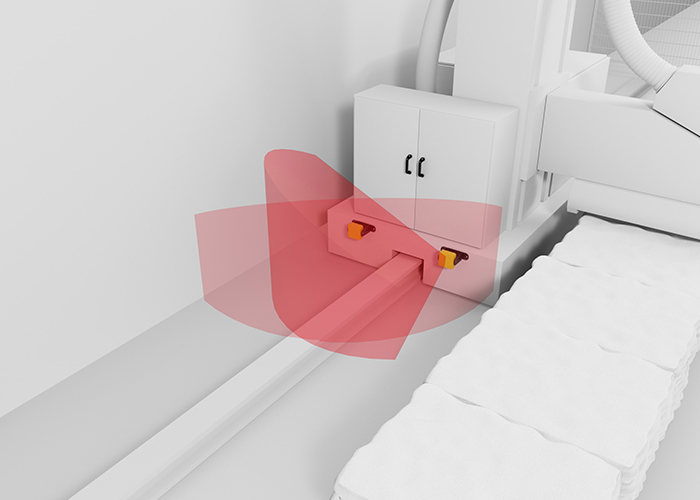

Transportation path safeguarding

Requirement:

The transportation path must be continuously monitored before and during automated operation to reliably detect people. Environmental material such as fibers or particles must not impair detection.

Solution:

Use the robust LBK radar system, which reliably detects people, even in challenging, dirty environmental conditions. Two sensors are activated for each direction of travel, and can be integrated into the system’s safety functions via a controller.