Access guarding with dynamic format adaptation

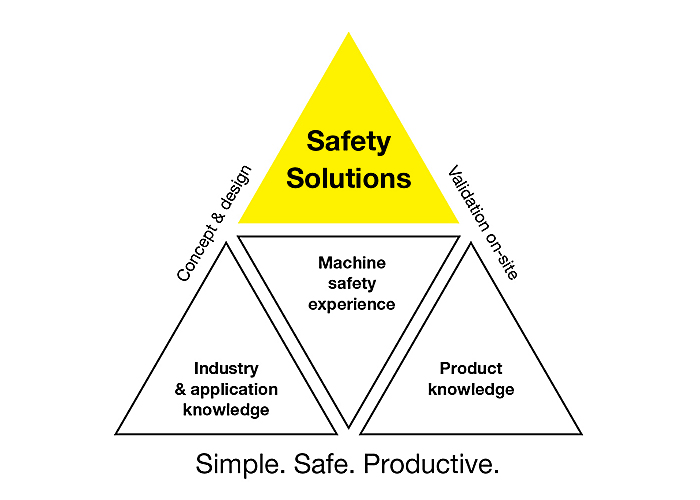

From risk assessment to validation: our safety solutions provide complete solutions for your systems. Our expert teams’ innovative safety concepts ensure efficient material flow, gapless safety and high availability of your system. Even in applications where classic concepts are pushed to their limits. Always with legal certainty, CE certification and compliance with standards. This makes implementation particularly easy for you.

One challenge with access guarding on conveyor lines is the handling of different sizes and positions of the transported goods. While it is possible to find integrated safety concepts for situations in which the size of the goods remains identical – for example, on the basis of muting functions – gaps in safety quickly arise if the width of the goods, the positioning of the goods on the pallet, or the positioning of the pallet on the conveyor belt changes. This particularly applies when guarding large openings for the area to the side of the transported goods.

With its superior safety concept, the Leuze safety solutions with dynamic format adaptation provide the perfect answer for these applications.

Requirement:

Pallets are automatically fed in and out by a conveyor belt. Access guarding must allow goods with changing width and at different positions on the pallet to be transported. The position of the pallet on the conveyor can also vary. At the same time, persons must be prevented from moving alongside the pallet.

Solutions:

Two vertically aligned safety laser scanners guard access. Measuring distance sensors (solution 1, left image) or the parallel measuring function of the scanners (solution 2, right image) determine the width and position of the goods and send this information to the Leuze safety system. This adjusts the protective field for the passage of goods accordingly.

Operating principle:

Two safety laser scanners produce a vertical protective field. The optical distance sensors installed on both sides next to the conveyor line (solution 1, left image) or the measurement function of the laser scanners (solution 2, right image) detect the width of the item and its position on the conveyor line. The safety system uses this information to release an appropriate area in the protective field through which the goods can be transported without interruption. Access remains safeguarded alongside the goods. After the goods have passed through the opened protective field area, the protective field is again reset to its original, closed state.

Advantages for you

- Continuous monitoring of the entire access area offers gapless safety during the transport cycles

- High reliability and availability

- Optimum protection against tampering

- Easily retrofittable

- Solution 1: Safety distance to the hazard smaller compared to solution 2

- Solution 2: No additional measuring distance sensors required

System components and safety parameters

| Safety sensor: RSL 400 safety laser scanner | |

|

Measuring sensors: ODS optical distance sensors (solution 1), measurement data output of RSL 400 safety laser scanners (solution 2) |

|

|

System control: Siemens SIMATIC S7 |

|

| Leuze safety program | |

|

PL d in accordance with EN ISO 13849-1, SILCL 2 in accordance with IEC 62061 |

|

| 2-channel safety output |