Sensor solutions for carding machines

First, the fibers are aligned to ensure uniform yarn quality. Subsequently, a raw yarn strand is produced in several processing steps and temporarily stored in bins before further processing.

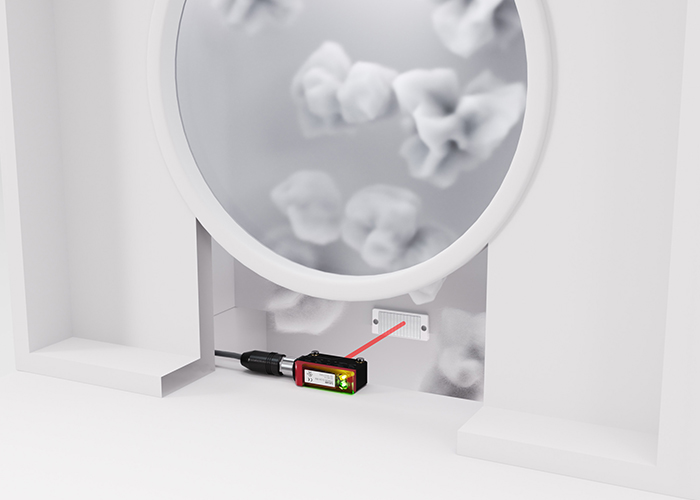

Inflow detection

Requirement:

A continuous supply of raw cotton is required to ensure an uninterrupted process flow. The material feed is monitored at the inflow connection.

Solution:

A compact, easy-to-integrate PRK 5B-type optical sensor with reflector reliably detects the presence of raw cotton. Bright status LEDs enable rapid, clear condition diagnosis, ensuring precise process monitoring.

Fiber alignment control

Requirement:

To optimize and homogenize fiber alignment, the combing process is controlled by precisely pulling and twisting the comb segments. This requires precise measurement of the distance between the individual comb parts so that any positional deviations can be detected and automatically compensated for.

Solution:

Up to five LISA-type inductive sensors with analog output continuously detect the relative positions of the comb segments. The sensor signals are processed by an amplifier and transmitted to the control, which ensures precise tracking and synchronization of the comb movement based on the measured values.

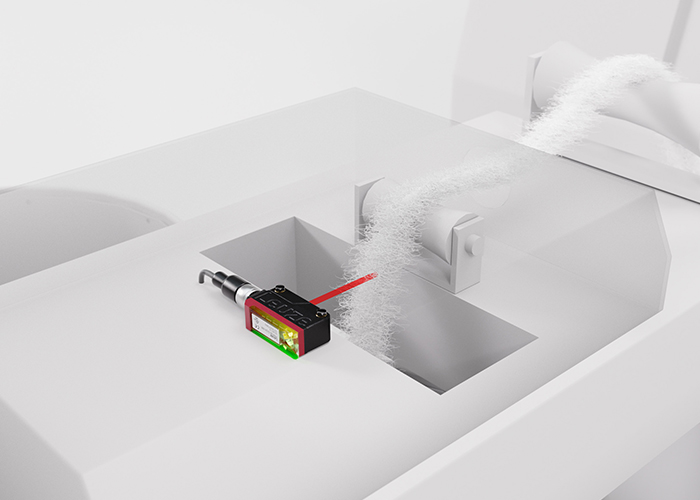

Raw yarn strand detection

Requirement:

The raw yarn strand is conveyed through the machine and deposited in collecting bins at the end of the process for further handling. Reliable process control requires accurate detection of both the yarn strand and the bin’s fill level. Simple, space-saving integration of the sensor technology into the existing machine design is essential here.

Solution:

Type HT 5B diffuse sensors are used to detect the raw yarn strand and to monitor the collecting bin’s fill level. These enable precise object detection even for yarn with varying surface structures. Thanks to their compact design, versatile connection options, and high installation tolerance, the sensors can be optimally integrated into the machine and the transfer area without impeding the material flow.

Collection container detection

Requirement:

Before the process begins, the collection bin’s presence must be reliably checked to ensure that the raw yarn strand can be properly picked up and made available for the next production step. Robust, failsafe detection is crucial to avoid downtimes and material losses.

Solution:

Optical sensors are generally used to monitor the presence of the bin. The ET 328 series’ cylindrical diffuse sensors are particularly suitable, as their defined light spot reliably blanks out any color and shape differences in the bins. This ensures stable detection regardless of material, color or surface structure.

Alternatively, our portfolio includes other designs – such as cubic sensor housings – for different installation situations and mechanical requirements.

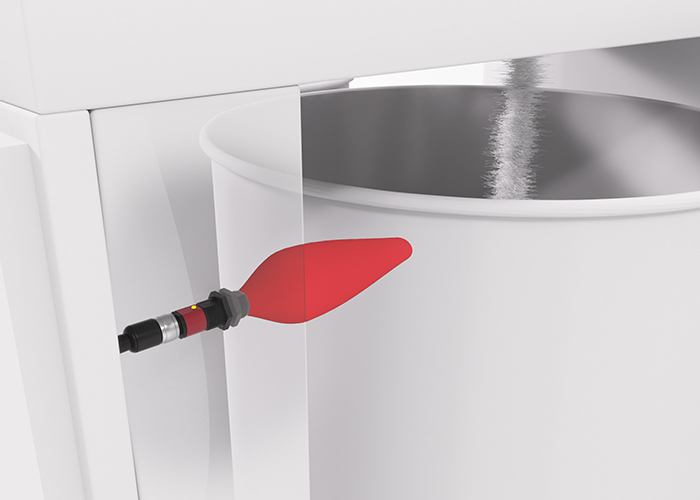

Locking of machine parts

Requirement:

To ensure operator safety, moving machine parts must remain locked during operation and only be able to be opened when the system is safely at a complete stop. The lock must reliably prevent protective covers or doors from being unlocked prematurely, while at the same time allowing easy integration into the machine’s safety concept.

Solution:

The L 200 series safety locking devices are specially designed for these sorts of applications. Their rotatable actuator head mean they can be flexibly adapted to different installation situations and ensure secure locking until the defined machine standstill is reached. For more demanding requirements, additional variants with higher safety categories, integrated operating elements, or alternative actuator designs are available to enable optimal adaptation to different machine concepts.

Flap status

Requirement:

Machines often have flaps or removable covers for maintenance and service purposes. During normal operation, the switching state of these openings must be reliably detected and connected to the safety control. This ensures that any opening during operation is detected and appropriate protective measures are automatically activated.

Solution:

The MC 300 series magnetic safety proximity sensors mounted directly on the movable flaps or covers provide an efficient and compact solution. They enable reliable condition monitoring without mechanical actuators.

Variants with RFID technology (RD 800 series) are available for applications with increased tamper protection requirements.