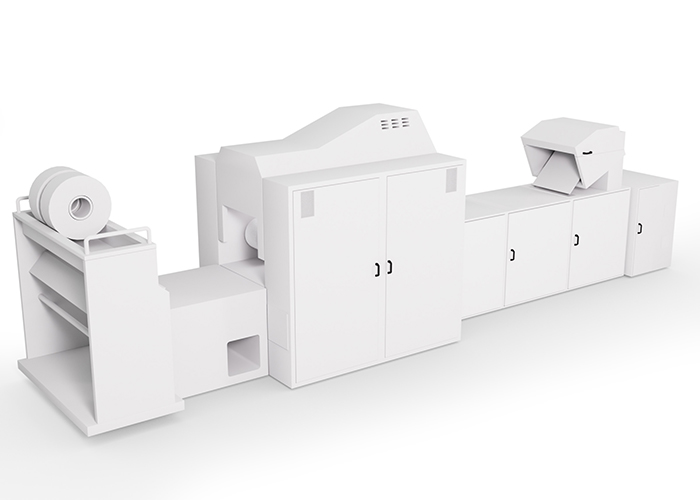

Sensor solutions for combing machines

After removing the raw yarn from the transport bin, the next process step involves targeted processing by twisting, straightening, and controlled pulling of the yarn strand. These measures optimize fiber alignment, reduce irregularities and significantly improve yarn quality. At the end of this process, a spool of high-quality raw yarn is produced, ready for the subsequent production steps.

Machine inflow

Requirement:

Before the process starts, the collection bin’s presence must be reliably checked to ensure that the raw yarn strand can be properly picked up and made available for the next production step. Robust detection is crucial to avoid downtimes and material losses.

Solution:

Optical sensors such as type ET 328 cylindrical diffuse sensors are suitable for presence control. The defined light spot reliably blanks out color and shape differences between the bins, ensuring stable detection regardless of their material or surface. Alternatively, our portfolio includes cubic sensor models and other designs to flexibly meet different installation and space requirements.

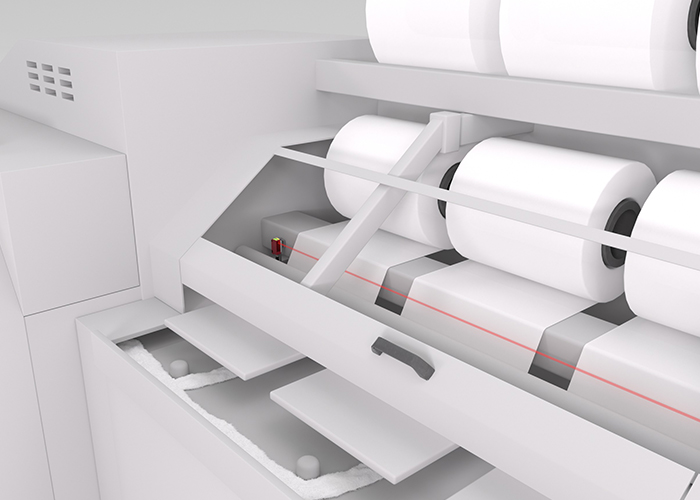

Fiber breakage

Requirement:

The coarse yarn tape must be processed and wound continuously, without any gaps or interruptions. This requires reliable detection of yarn breaks to identify process interruptions at an early stage and minimize downtime.

Solution:

Optical sensors can be used to detect breaks. Typically, a mini-format throughbeam photoelectric sensor, such as the LE / LS 3C, is installed at a defined position.

If the yarn strand falls off the track (break), the light beam is interrupted and the sensor reports the interruption. Alternatively, monitoring can be performed using continuous beam interruption. Any break in the light beam or free light axis is detected. This solution enables fast, reliable yarn break detection and supports smooth downstream processing.

Bobbin detection

Requirement:

Before beginning the winding process, the presence of the empty bobbin must be reliably verified to ensure uninterrupted operation. The solution must operate independently of color and occupy minimal space, allowing for easy integration into the existing machine layout.

Solution:

Diffuse sensors with background suppression, e.g. HT 3C, are suitable for detection. The sensor works independently of color, as the black/white error is minimal. Thanks to the large adjustment range, the sensor can be flexibly adapted to different winding positions. The compact design enables space-saving integration into existing machine designs.

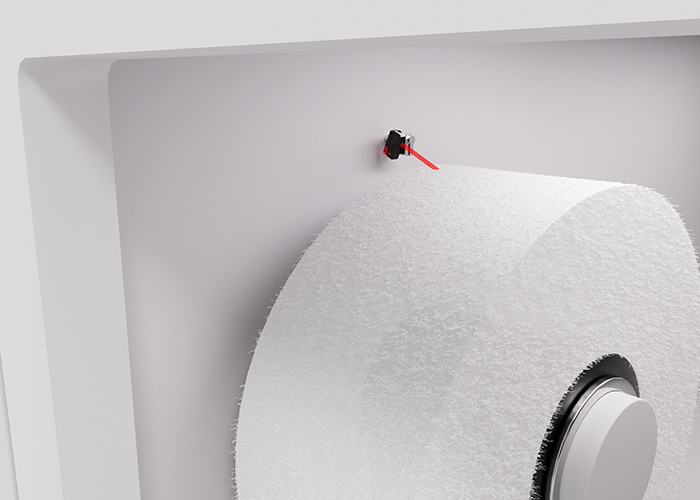

Full bobbin detection

Requirement:

To ensure that the bobbins are filled evenly, the ‘Bobbin full’ status must be reliably detected. The solution should be flexible enough to be used with different bobbin widths and have a one-piece, compact design to enable easy integration into existing spool winders.

Solution:

An HT 23 diffuse sensor is mounted slightly above the bobbin and aligned at a suitable angle. It detects when the upper switching point is reached and automatically triggers the cutting and bobbin change process. The one-piece design allows flexible adaptation to different bobbin widths and simplifies installation. Precise switching point monitoring ensures continuous and uniform bobbin filling.