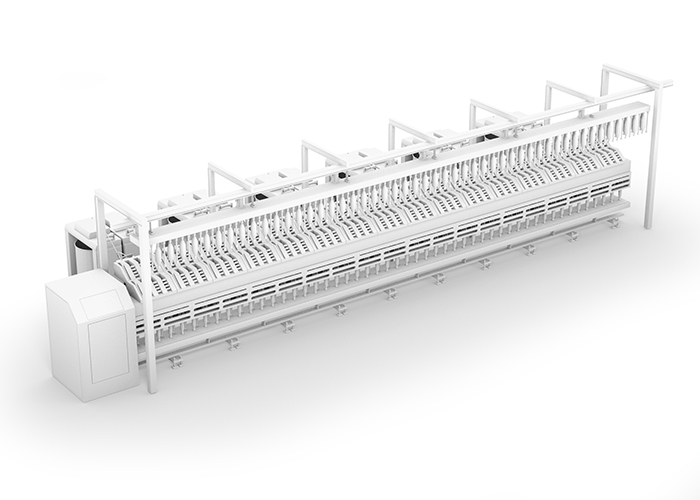

Sensor solutions for simplex machines

In the simplex machine, the raw yarn strand is processed by targeted twisting, winding and tensioning. These measures optimize the uniformity of the yarn, resulting in a high-quality raw yarn. It is supplied on suitable bobbins so it is available for subsequent spinning processes.

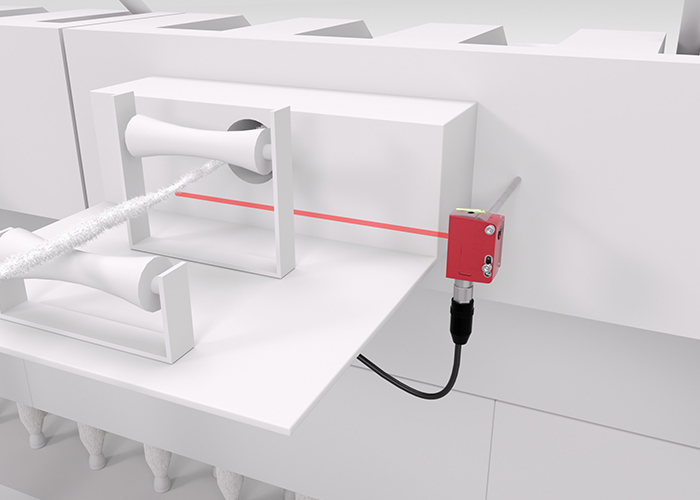

Raw yarn tension monitoring

Requirement:

To maintain consistent yarn quality and a stable process flow, the thickness and continuity of the raw yarn strand must be continuously monitored at the machine inflow. Tight tolerances and precise value output are required so that the downstream machine control system can detect deviations at an early stage and make process adjustments.

Solution:

The GS 754 measuring fork sensors with analog or data output meet these requirements perfectly: High level of precision and tight tolerances enable reliable diameter and interruption detection. Available sizes and resolutions allow flexible integration into different machine types. Continuous value output supports direct connection to the machine control system for automated process control.

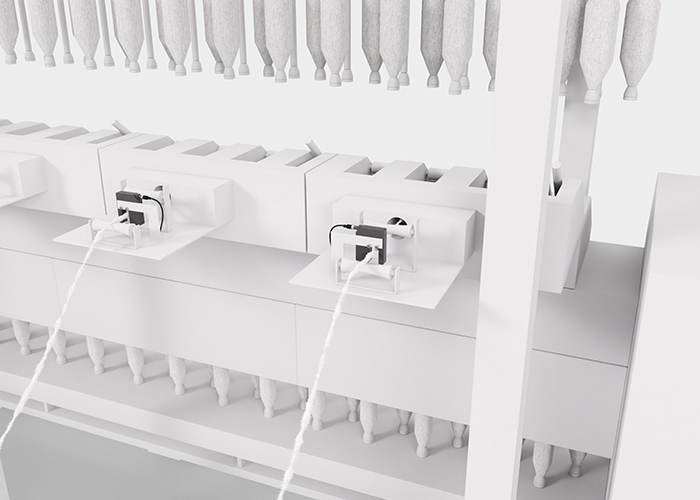

Breakage/cut detection

Requirement:

Reliable breakage detection must be performed at defined points along the yarn path to ensure uninterrupted progression through subsequent process steps. In the event of a yarn breakage, the yarn strand falls downwards, stopping the current process step. Precise and fast detection is crucial to minimize machine downtimes and material losses.

Solution:

Throughbeam photoelectric sensors, e.g. LE / LS 25C, which are mounted below the transport level, are suitable for detection. The yarn break is reliably detected as the light beam is interrupted by the falling yarn. Other sizes are available for different installation situations and spatial conditions to enable flexible integration into existing machine layouts. The solution ensures continuous process monitoring and supports automated control in the event of interruptions.

Checking bobbin removal

Requirement:

After the yarn improvement step, a defined quantity of yarn is automatically wound onto bobbins. In the machine, this process takes place in parallel for multiple bobbins at the same time.

Once the desired quantity has been wound, an automatic bobbin change is triggered in a defined position. Before refilling, it must be ensured that all bobbin positions are free to avoid collisions or incorrect filling.

Solution:

A throughbeam photoelectric sensor for long operating ranges, e.g. LE / LS 46C, is suitable for reliably checking the empty state. The sensor detects all bobbin positions across the entire width of the machine and checks the empty status. The new filling is only started after confirming that all spaces are free. The solution ensures safe, automated process control during bobbin changes and prevents material or machine downtimes.

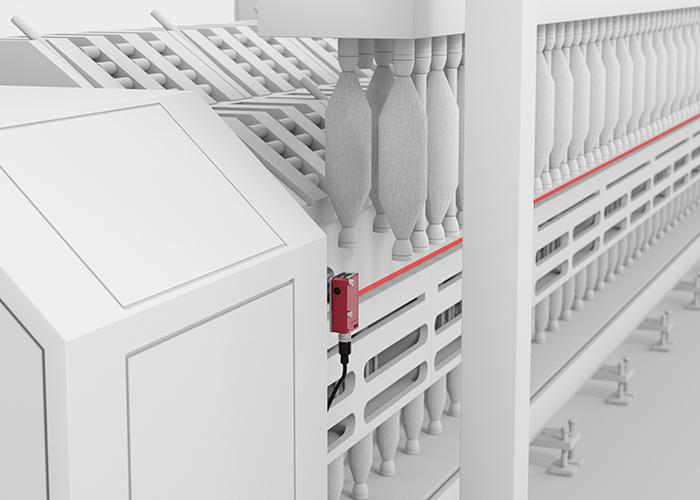

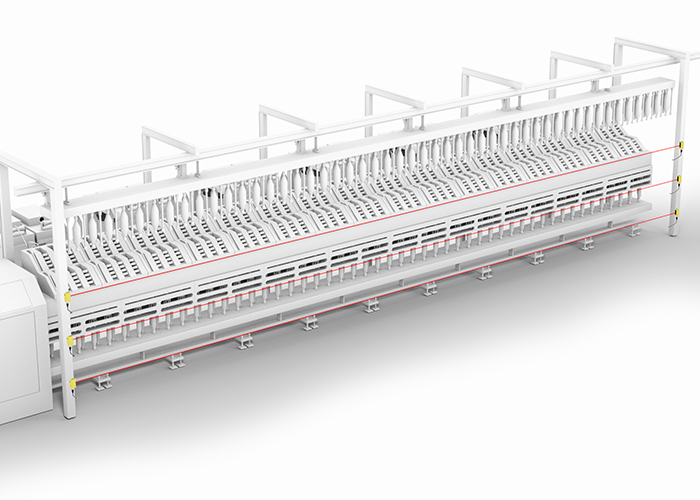

Access guarding around the machine

Requirement:

Safe access monitoring must be provided along the machine to prevent accidents involving employees during operation. Due to different design conditions, either multiple light beam safety devices or several single light beam safety devices are preferred to ensure complete safeguarding.

Solution:

Three pairs of SLS/SLE 46C safety devices are used for body detection and flexible mounting on the side of the machine. In combination with an MSI-TRM safety-related switching module, this results in a directive-compliant solution with correctly dimensioned beam spacing. A combined version in a single housing, MLD 500, is available for compact installations. The solution ensures flexible, secure safeguarding along the machine and fulfills all relevant safety guidelines.