Inductive sensors with IO-Link standard v1.1.4

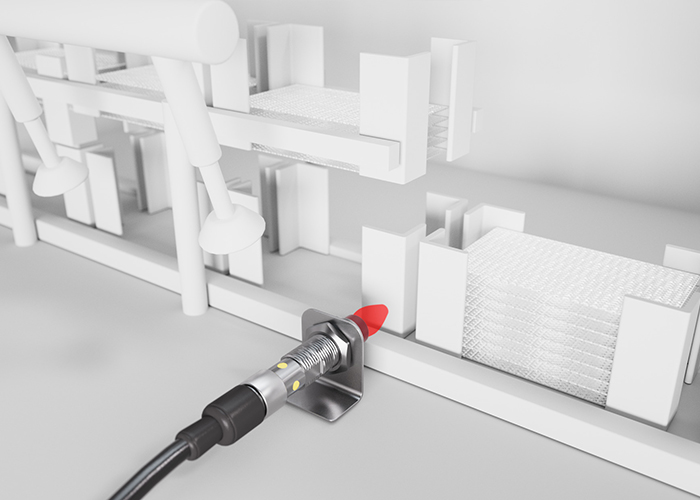

With an IO-Link interface, sensors can be seamlessly integrated into automation systems. The inductive proximity switches with IO-Link interface are easy to operate, parameterize and monitor (condition monitoring). They can be operated both in standard I/O mode (SIO) and in IO-Link mode, offering maximum flexibility.

SIO mode is the standard mode. When connected to an IO-Link master, IO-Link mode is automatically activated, allowing the sensor to be operated and configured via the master. These configuration settings are retained even after the sensor is switched off.

Configuration options:

- Setting the switching distance and hysteresis

- Timer functions for specific applications

- Advanced functions such as temperature alarms and frequency monitoring

Advantages for you

- Avoidance of machine downtimes: Continuous status monitoring of the sensors detects errors before they disrupt the production process.

- Fast reactive maintenance: Immediate identification of machine errors, which considerably speeds up the replacement of sensors.

- Predictive maintenance: Monitoring of operating time and temperature ranges to plan preventive maintenance measures, e.g. the precautionary replacement of sensors.

- Remote adjustment of the sensor settings: Adjustment of switching distances and hysteresis to different production conditions or format changes. Switching outputs are fully configurable (push-pull, PNP/NPN, NO/NC) for maximum application versatility.

Highlights

Monitoring of the machine or system

The status of the automated production or logistics system can be monitored and controlled perfectly thanks to IO-Link. Errors can be detected and rectified quickly – or even avoided through predictive maintenance.

Adjustment of the sensors to changed production conditions

The sensors can be parameterized “remotely” in the event of a changed product or changing environmental conditions. They can thus be adapted to the new situation without requiring any physical conversion.

Lower storage costs through standardization

The possibility of reprogramming the switching behavior and the switching output means that the variety of sensors in stock can be significantly reduced. This saves costs and simplifies maintenance.

Application

Speed measurement on a drive shaft

Requirement:

Solution:

Monitoring the position of semi-finished metal products in production

Requirement:

Solution:

Adjustment of switching distance and hysteresis when checking the presence of material carriers

Requirement:

Solution:

The inductive sensors with IO-Link interface are available in 3 different designs:

- M8 made of stainless steel for flush installation, with M8.3 connector.

- M12 made of nickel-plated brass for flush installation, with M12 connector.

- M18 made of nickel-plated brass for flush installation, with M12 connector.

Technical features

| Parameter | ISS 208MM.2/L-2E0-S8.3 | ISS 212MM.2/LX-4E0-S12 | ISS 218MM.2/LX-8E0-S12 |

| Operating range | 0 – 2 mm | 0 – 4 mm | 0 – 8 mm |

| Response time | ≤ 50 ms | ≤ 50 ms | ≤ 50 ms |

| Repeatability | ≤ 5% | ≤ 5% | ≤ 5% |

| Hysteresis | 1 – 20% | 1 – 20% | 1 – 20% |

| Switching frequency | ≤2000 Hz | ≤2000 Hz | ≤1300 Hz |

| Connection type | M8 3-pin | M12 4-pin | M12 4-pin |

| Housing dimensions | M8 x 40 mm | M12 x 50 mm | M18 x 54 mm |

| Temperature range | - 25°C … + 80°C | - 40°C … + 70°C | - 40°C … + 70°C |

| Protection class | IP 67 | IP 67 | IP 67 |