Diffuse sensors with background suppression

New laser distance diffuse sensor with TOF technology

Compact diffuse sensor for detection and measurement tasks with high operating ranges

The ODT 3CL1-2M and ODT 25CL1-3M diffuse sensors have been developed for applications where the presence of objects is to be detected and measurement values are to be output via IO-Link over long distances. The laser sensors with background suppression work with TOF (Time of Flight) technology and reach operating ranges of 2 m (ODT 3C) and 3 m (ODT 25C).

The switching sensors with measured value output have two independent switching points and can be used in many ways: In intralogistics, they can be integrated into shuttles for various applications, ensuring reliable positioning as well as presence and compartment occupation checks. For AGVs (automated guided vehicles), the diffuse sensors monitor e.g. the position of the transport material. Compact diffuse sensors with high operating ranges are also used in automobile production, e.g. to control robot grippers or for quality control. In the battery industry, battery cells can also be reliably detected from greater distances and at large angles despite their blue and/or glossy surface.

The 3C (11.4 mm x 34.2 mm x 18.3 mm) and 25C (15 mm x 42.7 mm x 30 mm) series include compact photoelectric sensors and diffuse sensors with long operating ranges and large functional reserves. We are expanding our distance sensors’ operating range with the ODT 3C and the new ODT 25C laser light scanners. The ODT 3C diffuse sensor with triangulation principle, already included in the 3C series, achieves operating ranges up to 150 mm and is suitable for packaging processes, for example.

Advantages for you

- 2in1 sensor: The detection and output of measurement values using just one sensor saves time and money during procurement, installation, commissioning and operation

- TOF technology: High operating range up to 3 meters makes applications over large distances possible

- Small, visible light spot thanks to laser light source

- Different housing sizes and screw-on positions: Use appropriate to the space available in the respective application

- Integrated object test: Mode with brightly flashing light spot to check the function reserve

- Protection class IP69K: Allows use in harsh conditions

- Output of process data via IO-Link: Extensive diagnostic data from the device, e.g. signal quality, temperature value, object counter and warning

- High tolerance when detecting different objects at angles

Highlights

The ODT 3C and the ODT 25C solve detection tasks and provide distance information to the machine controller. To perform these tasks with just one sensor, the sensor must supply both switching information and measurement values. For the customer, this saves time and money during procurement, installation and commissioning as well as during operation. The two independently adjustable switching points enable shuttles, for example, to optimally set and vary their speed to transport goods quickly to their target destination.

The TOF (time of flight) technology enables operating ranges of several meters. This technology combines the sensor with its very small, space-saving housing (ODT 3C: 11.4 mm x 34.2 mm x 18.3 mm or ODT 25C: 15 mm x 42.7 mm x 30 mm) with a long operating range – all this as a sensor with background suppression. The laser diffuse sensors can be used in many applications: e.g. on shuttles, AGVs and stacker cranes as well as in the automotive industry and packaging processes.

The operating range can be adjusted numerically via IO-Link (Remote Set Distance). The device calibration also enables a high level of accuracy when adjusting via remote. As a result, the switching points in the device are adjusted almost entirely independently of reflections when adjustments are made via IO-Link and when the device is exchanged for a replacement part. The high accuracy and the device calibration are also extremely beneficial when it comes to changing the device, because the presetting can be transferred to the new device loss-free via IO-Link without having to repeat the teach.

The sensor supplies extensive diagnostic data from the device, e.g. temperature value, signal quality, object counter and warning. Measurement value transmission in IO-Link for monitoring a specific window area.

Application

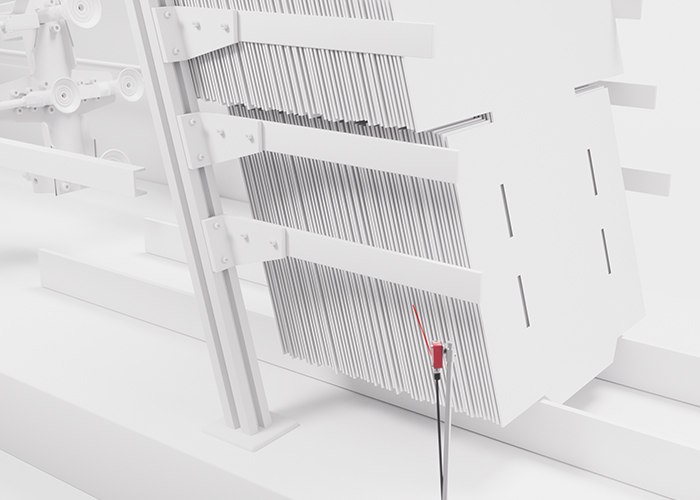

Intralogistics: Compartment occupation check with shuttles

Requirement:

Shuttles must transport goods safely, identify free spaces reliably and avoid collisions. Before a container or carton can be placed on the shelf, it must be checked whether the space is free.

Solution:

The ODT 3C and ODT 25C scanning sensors can be used for many applications on a shuttle. The sensors even detect color-structured objects reliably with an operating range up to two or three meters.

Intralogistics: Fine positioning of an AGV

Requirement:

AGVs transport pallets in production and logistics facilities. To detect the pallet with the load receptacle, it is necessary to detect where the spaces between the pallet feet are located and whether they are freely accessible.

Solution:

The ODT 3C optical sensors monitor the correct retrieval and transfer of the pallets. They operate independently of the material and have precise switching points. Two digital switching outputs mean that the sensors can also be used for compartment fine positioning.

Intralogistics: Determining the position of the pallet on the load receptacle

Requirement:

When picking up a pallet, the distance between the pallet and the end face of the load receptacle must be determined to stop the forward movement in good time.

Solution:

The ODT 3C and ODT 25C distance sensors determine the distance to objects reliably and with high repeat accuracy. Thanks to the TOF technology, the sensors have a high operating range of two or three meters.

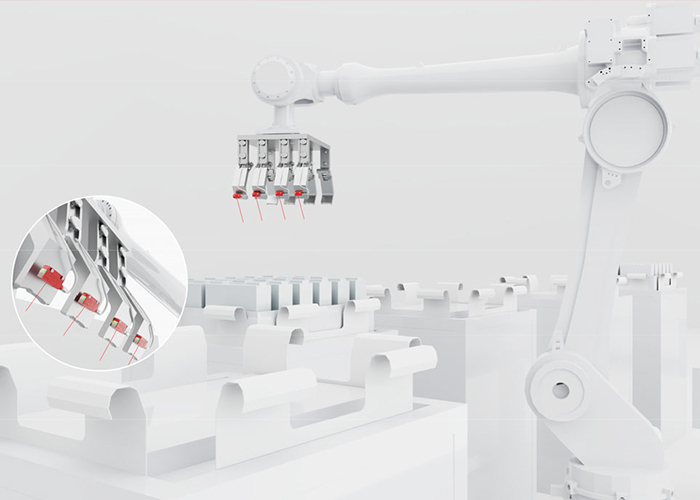

Automotive industry: Removal of vehicle body parts from a magazine using a gripper

Requirement:

In the automotive industry, robot cells are frequently used, e.g. in vehicle body construction. In these cells, robot grippers must reliably collect e.g. vehicle body parts from magazines. This process must be performed without problem despite different material surfaces and magazine fill levels.

Solution:

The ODT 3C or ODT 25C diffuse sensor with background suppression and TOF technology has two independent switching points and an operating range of three meters. When the first switching point is reached, a signal is sent to the robot gripper telling it to slow down its movement. The second switching point provides the gripping signal. The measurement values are used for monitoring the process and detecting empty magazines. The sensor’s design allows it to be integrated in the gripper of the robot arm.

Packaging processes: Carton feeding

Requirement:

In a packaging machine, the fill level of cartons must be monitored continuously and an alert must be triggered to ensure that they are refilled in good time.

Solution:

The two independent switching points allow the ODT 3C or ODT 25C to emit a refilling signal or provide information on the fill level at two defined fill levels. Furthermore, the current fill level can be queried at any time using the measurement values via IO-Link.

Battery production: Presence detection of battery cells and battery packs

Requirement:

During battery production, robots must pick up individual cells from load carriers and transport them to the next process step. To do this, the robot’s gripper must reliably detect the battery cell’s presence on the load carrier and place it precisely at the next step’s ‘target positions’.

Solution:

The easily integrated compact ODT 3C distance sensors with focused laser spot and long operating range of up to 2 m with ToF technology detect even small objects regardless of the surface. Adjustments can be made at any time via the IO-Link interface and a distance value can be used for transparent process control.

Technical features

| ODT 3CL1-2M | ODT 25CL1-3M | |

| Operating principle | Diffuse sensors with background suppression | Diffuse sensors with background suppression |

| Operating range | 2,000 mm | 3,000 mm |

| Light source | Laser, red (Class 1 laser) | Laser, red (Class 1 laser) |

| Switching frequency | 7–15 Hz, depending on reflectivity | 7–15 Hz, depending on reflectivity |

| IO-Link | V1.1 (COM3) | V1.1 (COM3) |

| Switching output | IO-Link variants: 2 independent switching outputs, push-pull Variants without IO-Link: Two antivalent switching outputs | IO-Link variants: 2 independent switching outputs, push-pull Variants without IO-Link: Two antivalent switching outputs |

| Operation | Teach button | Teach button |

| Protection class | IP67/IP69K | IP67/IP69K |

| Certifications | CE, UL, ECOLAB | CE, UL, ECOLAB |

| Connection | M8 / pigtail / cable | M8 / M12 / pigtail / cable |

| Housing dimensions (W x H x L) | 11.4 mm x 34.2 mm x 18.3 mm | 15 mm x 42.7 mm x 30 mm |

Article list

Product selector

- Series: 3C

- Operating principle: Diffuse reflection principle with background suppr...

- Operating range, max.: 0.015 ... 0.15 m

- Design: Cubic

- Series: 23

- Operating principle: Diffuse reflection principle with background suppr...

- Operating range, max.: 0.005 ... 0.06 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C, 25C

- Operating principle: Distance diffuse sensor with background suppressio...

- Operating range, max.: 0.07 ... 3 m

- Design: Cubic

- Series: 25C

- Operating principle: Diffuse reflection principle with background suppr...

- Operating range, max.: 0 ... 0.5 m

- Design: Cubic

- Series: 55C

- Operating principle: Diffuse reflection principle with background suppr...

- Operating range, max.: 0.005 ... 0.05 m

- Design: Cubic

- Series: 25C

- Operating principle: Diffuse reflection principle with background suppr...

- Operating range, max.: 0 ... 0.8 m

- Design: Cubic