Tamaño mínimo, seguridad máxima

El escáner láser de seguridad más pequeño del mercado: el RSL 200 de Leuze

En la automatización industrial, la eficiencia y la seguridad deben ir de la mano: es necesario proteger de forma fiable a las personas, las máquinas y los procesos sin obstaculizar los procesos de producción. Sin embargo, el espacio es limitado en líneas de producción estrechas, en sistemas de transporte sin conductor y en robots. Es aquí donde entra en escena el nuevo escáner láser de seguridad ultracompacto RSL 200 de Leuze: Al tratarse del escáner láser de seguridad más pequeño del mercado, es posible integrarlo sin esfuerzo y utilizarlo de manera flexible para proteger zonas de peligro y puntos de acceso.

Los escáneres láser de seguridad están adquiriendo un protagonismo creciente en casi todos los sectores. No en vano, estos versátiles dispositivos son indispensables en muchos casos para garantizar los más elevados estándares de seguridad para la protección de las personas. Gracias a sus campos de protección y de aviso configurables, se pueden utilizar de manera muy flexible para la protección de zonas de peligro y accesos, en aplicaciones tanto fijas como móviles. Un campo de aplicación típico es la protección de las zonas de trabajo peligrosas de una máquina contra el acceso y la presencia de personas. Los escáneres láser de seguridad también son ideales para proteger robots móviles autónomos (AMR) y sistemas de transporte sin conductor, también conocidos como vehículos de guiado automático (AGV).

Seguridad máxima en espacios mínimos: el futuro de los escáneres láser

Los escáneres láser de seguridad modernos deben cumplir una amplia gama de requisitos a la vez: no solo deben desempeñar su cometido principal de apagar de forma segura máquinas o sistemas, sino que no deben mermar la disponibilidad de las máquinas ni provocar tiempos de inactividad innecesarios. Además, se espera que los escáneres láser de seguridad tengan un alcance efectivo y un ángulo de exploración impresionantes, mientras que el operador del sistema da por sentadas clasificaciones de seguridad conforme al Tipo 3, SIL 2 y PLd. Asimismo, el operador del sistema debe poder confiar en una configuración y un diagnóstico cómodos, que puedan llevarse a cabo de forma fácil e intuitiva mediante diversas interfaces, tales como Bluetooth, USB o Ethernet TCP/IP. Por último, pero no menos importante, los escáneres láser de seguridad se seleccionan según su tamaño. Al fin y al cabo, debido a la creciente automatización está aumentando la importancia de la eficiencia espacial en muchos entornos de producción. Los sistemas se están volviendo cada vez más complejos, al tiempo que disminuye el espacio disponible para la tecnología de seguridad. A menudo se cuenta con poco sitio para ello, especialmente para el uso móvil en los AVG.

Se requieren soluciones innovadoras para superar estos retos. La Sensor People de Leuze está estableciendo nuevos estándares de factor de forma con su avanzada tecnología de escáneres láser de seguridad, que mantiene al usuario como la máxima prioridad. El escáner láser de seguridad ultracompacto RSL 200 es actualmente el dispositivo más pequeño del mercado. Incorpora tecnología LiDar de última generación en un espacio mínimo de solo 80 x 80 x 86 milímetros. Esto facilita su integración incluso en espacios extremadamente reducidos, ya sea en aplicaciones fijas o móviles. Si se requieren alcances efectivos más largos se puede utilizar el RSL 400, de mayor tamaño y con un alcance efectivo de hasta 8,25 metros.

Instalación sencilla hoy

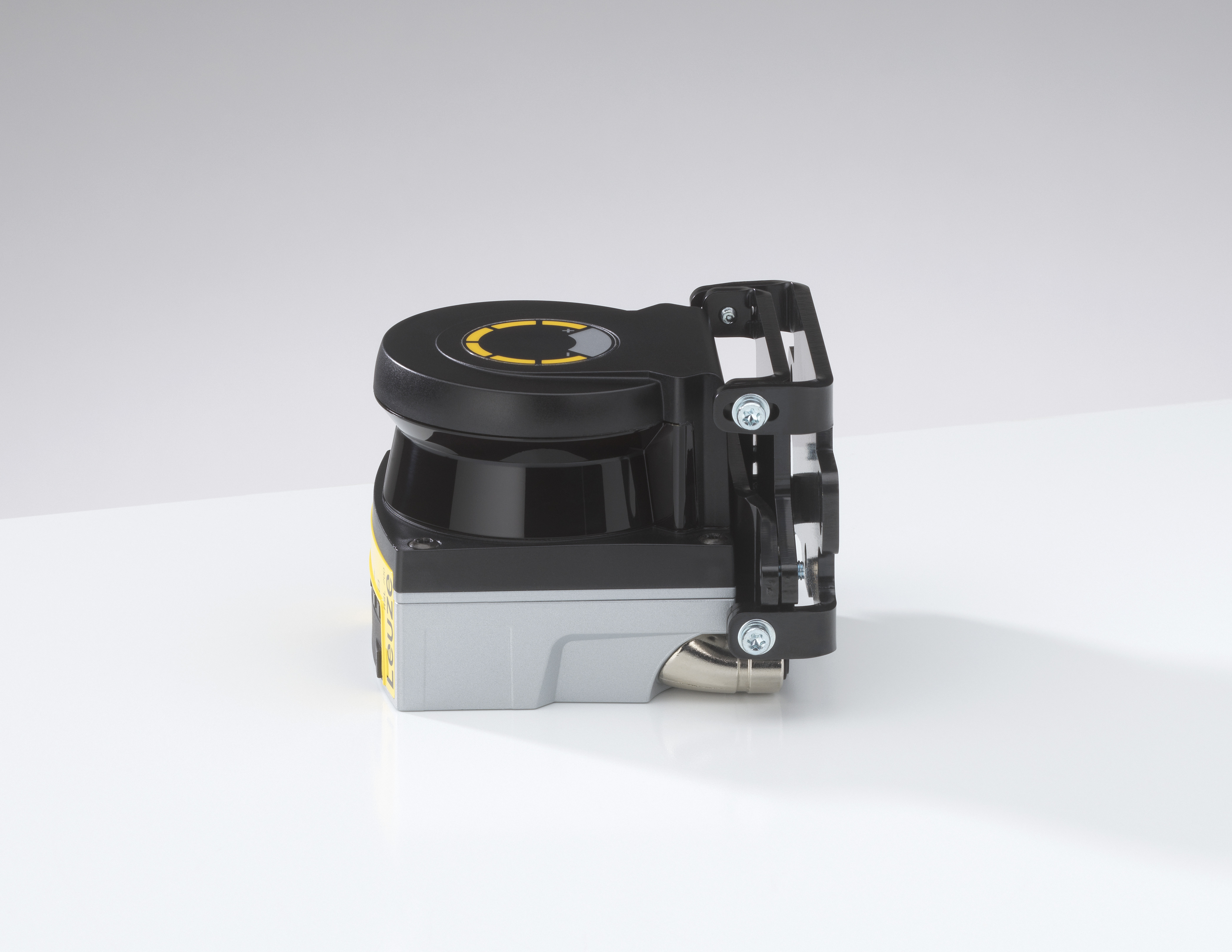

El escáner de seguridad compacto de Leuze ofrece al usuario más opciones para una instalación sencilla y más flexible, especialmente en entornos confinados, gracias al ahorro de espacio que permiten su escuadra de montaje compacta o su sistema de conexión. Los accesorios de montaje adecuados son clave para una integración rápida. Por este motivo, Leuze ha desarrollado su propia escuadra de montaje innovadora para el RSL 200, que posibilita una fijación sin esfuerzo y permite alinear en horizontal y vertical el nivel de exploración del escáner láser de seguridad.

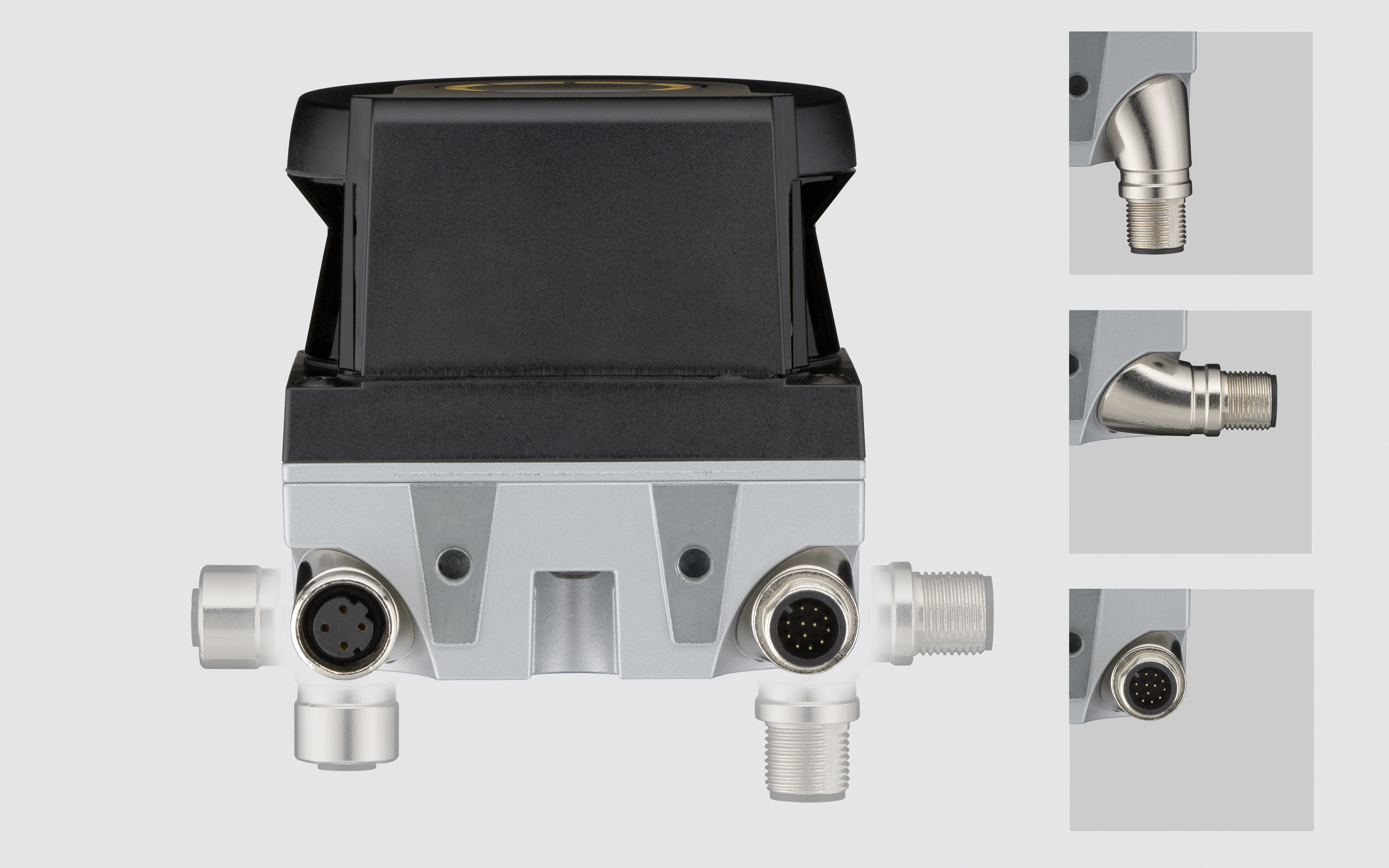

También se garantiza un mantenimiento sencillo: el RSL 200 se puede sustituir con facilidad y rapidez con tan solo cuatro tornillos, y los parámetros del sensor se pueden transferir del sensor antiguo al nuevo mediante una tarjeta de memoria, sin necesidad de conocimientos sobre sensores. Tampoco las conexiones y los cables deben convertirse en obstáculos. Las conexiones M12 giratorias del escáner láser RSL 200 posibilitan un enrutamiento de cables extremadamente flexible para E/S, alimentación eléctrica y transmisión de datos. Se trata de criterios esenciales, en particular para el uso en AVG pequeños.

La Sensor People también ofrece una nueva aplicación de diagnóstico móvil que permite obtener cómodamente información de estado aunque el escáner láser esté instalado en ubicaciones de difícil o imposible acceso.

Gracias a la innovadora escuadra de montaje especialmente desarrollada para el RSL 200, resulta muy fácil alinear el escáner láser de seguridad en horizontal y en vertical. Si se requiere mantenimiento, se puede sustituir el escáner láser con rapidez y facilidad mediante tan solo cuatro tornillos.

Adaptado a todos sus requisitos

Para el funcionamiento óptimo de un escáner láser de seguridad también son importantes sus valores «internos». Por ejemplo, el ángulo de exploración debe ser lo suficientemente grande para desempeñar de forma fiable la tarea de seguridad específica de la aplicación, p. ej., para cubrir por completo puntos ciegos o zonas difícilmente visibles detrás de máquinas o cintas transportadoras. Asimismo, debe ser capaz de proteger AVG/AMR omnidireccionales pequeños en cualquier dirección: por ejemplo, el RSL 200 de Leuze ofrece un ángulo de exploración de 275 grados con un alcance efectivo de tres metros. El gran ángulo de exploración permite al usuario garantizar una protección integral con tan solo dos dispositivos posicionados en diagonal, incluso teniendo en cuenta las tolerancias de montaje.

32 grupos conmutables de campos de protección y de aviso permiten al usuario del AGV/AMR ajustar continuamente la velocidad y la dirección de desplazamiento. Gracias a ello, las áreas monitorizadas se pueden adaptar de forma óptima a trayectorias curvas, distintas velocidades y diversos estados de carga.

Resumen

La última generación de escáneres láser de seguridad empieza con el RSL 200. Sus dimensiones ultracompactas permiten integrarlo con facilidad incluso en espacios extremadamente reducidos, en aplicaciones tanto fijas como móviles. También ayudan a este respecto ventajas tales como el ahorro de espacio con la innovadora escuadra de montaje y las conexiones M12 giratorias. Además, la aplicación de diagnóstico móvil de Leuze permite a los operadores del sistema obtener vía Bluetooth toda la información de estado cómodamente y en cualquier momento, aunque el escáner láser esté instalado en una ubicación inaccesible o de difícil acceso.

Director del área de negocio Safety de Leuze