Machine safety in Europe

The European Union (EU) consists of 27 member states with approximately 450 million residents. The member states of the EU have set up bodies that apply across the Union, to which they have transferred parts of their single state sovereignty. The EU Commission and EU Council issue EU Directives with basic requirements that must then be adopted by the member states into national law. European standards organizations, CEN, CENELEC and ETSI, are commissioned to draw up EU standards that technically solidify the applicable directives and legal provisions.

EU Directives

The AEUV contract regulates general cooperation between the EU member states e.g. with regard to EU directives that every member state must implement in its national legislation by the end of a transition period. Article 114 deals with the dismantling of trade barriers and Article 153 addresses social issues. Of the many different EU directives, the following are of particular relevance to machine safety:

- EU single market directives, which regulate the free movement of goods

- EU safety at work framework directives, which lay down fundamental requirements regarding the protection of employees

To simplify the implementation of the rather technical requirements of EU directives in the respective national legislation, EU regulations (e.g. basic regulation on data protection) are increasingly being enacted. These EU regulations, unlike EU directives, which serve as a template for implementation by governments of the member states, constitute direct law.

EU single market directives are the basis for the free movement of goods within the EU. In order to dismantle trade barriers in the EU single market, over 20 EU single market directives have been drawn up for product groups and product aspects. Affected products may only be distributed if they satisfy the basic requirements of the relevant EU directives.

If a product complies with the relevant harmonized EU standards assigned to a EU directive, it is assumed that the basic safety and health protection requirements are met. This is referred to as the "presumption of conformity" of a harmonized standard: the user of a standard only needs to prove that it has complied with the specified standards – but not that the applied standards adequately reduce the residual risks.

A manufacturer can also use technical solutions other than those described in the standards, provided that an equivalent safety level is proven. In this case, however, the burden of proof lies with the manufacturer.

Fulfillment of the basic requirements is determined in a formal conformity assessment procedure. Depending on the potential risk of the products, this is largely the responsibility of the manufacturer.

Key EU directives for machine safety:

| EU Directive | Description |

| 2006/42/EC | Machinery directive |

| 2014/35/EU | Low voltage directive |

| 2014/53/EU | RED directive (Radio equipment directive) |

| 2014/30/EU | EMC directive |

| 2014/34/EU | ATEX directive |

| 2009/105/EC | Pressure vessel directive |

| 2014/68/EU | Pressure equipment directive |

| 2003/10/EC | Noise Directive |

| 2001/95/EC | Product safety directive |

Safety at Work Framework Directive 89/391/EEC contains minimum requirements and general basic principles for the prevention of work-related hazards, for safety and health protection, for minimizing and eliminating risk and accident factors, and for the appropriate instruction of employees. These are minimum requirements. Each EU Member State may increase the protection level in its national implementation or, for example, set higher test requirements.

Key directives for EU occupational safety:

| EU Directive | Description |

| 89/391/EEC | Safety at work framework directive |

| 2009/104/EC | Use of work equipment directive |

| (EU) 2016/425 | EU regulation on personal protective equipment |

The Machinery directive 2006/42/EC

Machinery directive 2006/42/EC regulates a uniform level of safety for machines in order to enable free merchandise traffic and distribution within the European Economic Area. It applies to manufacturers and distributors of machinery and devices, but not to operating companies. The Machinery Directive can be found in its original text at www.eur-lex.europa.eu.

Structure and content of the Machinery Directive:

| Description | Contents | Number of pages |

| Recitals | No. 1 - 28 | 3 |

| Part available | Article 1 - 28 | 8 |

| Annex I | Essential health and safety requirements relating to the design and construction of machinery | 30 |

| Annex II | Declarations: EU declaration of conformity, declaration of incorporation | 1 |

| Annex III | CE marking | 1 |

| Annex IV | Categories of machinery to which one of the procedures referred to in Article 12(3) and (4) must be applied | 1 |

| Annex V | Indicative list of the safety components referred to in Article 2(c) | 1 |

| Annex VI | Assembly instructions for partly completed machinery | 1 |

| Annex VII | Technical documents for machinery | 2 |

| Annex VIII | Assessment of conformity with internal checks on the manufacture of machinery | 1 |

| Annex IX | EC type-examination | 2 |

| Annex X | Full quality assurance | 2 |

| Annex XI | Minimum criteria to be taken into account by Member States for the notification of bodies | 1 |

| Annex XII | Correlation table with Directive 98/37/EC | 8 |

The number of pages indicates that Annex I is the most important part of the Machinery Directive. Application of Annex I by the manufacturer involves conducting of the risk assessment and implementation of suitable protective measures. This is the most important element to ensure construction of a safe machine and accordingly requires the greatest amount of time and effort.

Machine

A "machine" in terms of the Machinery directive is "an assembly, fitted with or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application".

Furthermore, various safety-relevant parts such as safety components are regarded as a "machine" in terms of the Machinery directive.

Machines may be put into circulation in Europe only if they have a valid CE marking. This also applies to machines that are manufactured for own use by an operating company as well as to existing machines that have been substantially modified by the operating company or by an integrator.

Partly completed machine

A "partly completed machine" in terms of the Machinery directive is " an assembly which is almost machinery but which cannot in itself perform a specific application. A drive system is a partly completed machine. Partly completed machinery is only intended to be incorporated into or assembled with other machinery or other partly completed machinery or equipment, thereby forming machinery to which this Directive applies".

Quasi machines that are not operational on leaving the factory and only receive their specific functionality through e.g. programming, are partly completed machines. This includes e.g. the drive units already mentioned in the definition, but also industrial robots.

In accordance with the Machinery directive, partly completed machines must be delivered with a declaration of incorporation. The CE marking must be performed by the machine builder or system integrator together with the then "complete" machine.

Assembly of machinery

An "assembly of machinery" exists when multiple individual machines, partly completed machines and other components interact, are arranged and actuated so closely that they can only function usefully as an assembly. This requires both a production-related and a safety-related relationship to exist between all elements. This relationship must be so close that the assembly of the elements must be regarded as a unit. Consequently, this assembly which must be regarded as an autonomous unit requires a separate CE marking irrespective of whether or not individual components of this unit already have a CE marking – the assembly of machinery is a machine in its own right. An essential requirement for the CE marking of an assembly of machinery is a risk assessment of the assembly. In order to do this earnestly, the manufacturer of the assembly of machinery must obtain the necessary information from the manufacturer of each of the elements – a task that is not always straightforward.

A production line consisting of individual machines does not usually require its own CE marking because it is frequently the case here that the production line does not form an assembly of machinery. If an element of a presumed assembly of machinery can be removed relatively easily and replaced by another equivalent element without causing substantial modification of a control system assigned to the assembly of machinery, this is probably not an "assembly of machinery" in terms of the Machinery directive.

As applicability of the Machinery directive with respect to placing individual machines on the European market is limited, for a "normal" production line consisting of individual machines it unfortunately does not define a document providing an alternative to an EU declaration of conformity. Here, in public law according to the Machinery directive, there is no additional document that applies to the entire line. Due to uncertainty or for convenience, so-called "overall CE declarations" or even "declarations of incorporation" are often issued in practice for entire production lines. According to the Machinery directive, however, a switch-on prohibition is associated with a "declaration of incorporation" – the declaration after all defines the machinery as a partly completed machine.

If required/on request, Leuze recommends issuing a "declaration of integration" based on private law for a normal production line. This declaration of integration indicates that no "assembly of machinery" exists in terms of the Machinery directive.

The Machinery directive not only governs products of a machine manufacturer or system integrator in the European Economic Area, but also:

Machines that an operating company manufactures itself for own use in the European Economic Area.

- Imported used or new machines from a third country outside of the European Economic Area. This also applies e.g. in the case of a used machine that is put into circulation for the first time in the European Economic Area.

- New or used machines that are put into circulation for the first time in the European Economic Area by non-European subsidiaries (e.g. multinational companies). This also applies in the case of exclusively own use.

In addition to machines, the following also fall under the scope of the Machinery directive:

- Replaceable equipment

- Load receptacles

- Chains/ropes/straps for lifting purposes

- Removable joint shafts

- Lifting devices with a travel speed of up to 0.15 m/s of the load carrier, at a travel speed in excess of 0.15 m/s, they are subject to the Lift directive (if they are not covered by its rules of exception)

- Construction site lifts

- Safety components

All affected products must be distributed with the CE marking, declaration of conformity and the necessary user information.

The following do not fall under the Machinery directive, e.g.:

- Safety components that are intended only as spare parts

- Equipment on fairgrounds

- Machinery for nuclear use

- Weapons and machinery for military purposes

- Vehicles

- Mining machinery

- Stage equipment

- Electrical devices for domestic use, audio/video, information technology, office equipment, electric motors, switching and control devices, transformers

What do machine manufacturers and distributors have to comply with?

- The basic safety requirements of Annex I must be met. This means that early in the design phase the designer must perform a parallel risk assessment so that all required measures for risk reduction are already considered in the machine’s construction phase.

- The technical documentation for the machine including measurement and test results must be up to date and complete and must be archived for at least 10 years. It must be possible to present the documentation at the request of national authorities.

- The user information must contain all safety-relevant details regarding intended use, residual dangers and possible misuse of the machine.

- One of three possible conformity assessment procedures must be performed. For machines that are not listed in Annex IV (List of particularly dangerous machines and safety-relevant components), the manufacturer itself can perform the conformity assessment procedure.

- The manufacturer compiles a declaration of conformity and thereby certifies observance of the requirements from the Machinery directive and from any other applicable EU directives.

- Finally, the manufacturer affixes the CE mark.

The user information for partly completed machines differs from that for (complete) machines. While machines have to be delivered with warning notices and a set of operating instructions in the language of the country in which the machine is distributed, a set of assembly instructions as defined in Annex VI (Assembly instructions for partly completed machinery) must be enclosed with a partly completed machine. Partly completed machinery too can be put into circulation as long as it has a CE marking – however, this machinery must then comply with other EU directives such as the low voltage directive or EMC directive. An EU declaration of conformity with reference to the Machinery directive as well as all EU directives referenced by the used partly completed machines must then be issued by the integrator or the manufacturer of the complete machine and enclosed with the machine documentation.

The Machinery directive defines three conformity assessment procedures, at the end of which, provided that all steps are successfully completed, the CE mark is granted.

Procedure in accordance with Machinery Directive 2006/41/EC to obtain the declaration of conformity for

Machines and safety components

The Machinery directive defines extremely precisely the expected content of the EC declaration of conformity for a (completed) machine and for the declaration of incorporation of a partly completed machine.

| Content of EU declaration of conformity |

| Company name and complete address of the manufacturer and its authorized representative, if applicable |

| Name and address of the person who is authorized to compile the technical documents. This person must be resident in the European Community. |

| Description and identification of the machine, including general designation, function, model, type, serial number and commercial name. |

| A clause in which it is expressly declared that the machine complies with all relevant provisions of this directive, and, where applicable, a similar clause in which conformity with other directives and/or relevant provisions with which the machine complies is declared. The references as per publication in the Official Journal of the European Union must be specified. |

| If applicable, the name, address and identification number of the notified body which performed the test procedure named in Annex IX (EC type examination), as well as the number of the EC type examination certificate. |

| If applicable, the name, address and identification number of the notified body which approved the comprehensive quality assurance system named in Annex X (Full quality assurance). |

| If applicable, the references to the applied harmonized standards according to Article 7, Paragraph 2. |

| If applicable, the references to the other applied technical standards and specifications. |

| Date and place of the declaration. |

| Information on persons authorized to issue this declaration in the name of the manufacturer or its authorized representative and the signature of this person. |

It is often the case that not only conformity with the Machinery directive has to be declared for machines, but where necessary also conformity with the EMC directive, the RED (Radio equipment directive), the ATEX directive and other directives. All relevant EU directives must be given in exactly one declaration of conformity for the machine, not separately in various declarations of conformity for each directive. The electrical equipment of machines is covered by the harmonized standard EN 60204-1 (Safety of machinery – Electrical equipment of machines – Part 1: General requirements). The Low voltage directive (2014/35/EU) is therefore not named in a EU declaration of conformity for machines.

| Contents of the declaration of incorporation |

| Company name and complete address of the manufacturer of the partly completed machine and its authorized representative, if applicable. |

| Name and address of the person who is authorized to compile the relevant technical documents. This person must be resident in the European Community. |

| Description and identification of the partly completed machine, including general designation, function, model, type, serial number and commercial name. |

| A declaration of which basic requirements of the machinery directive are applied and upheld. In addition a declaration that the specific technical documents were compiled in accordance with Annex VII (Technical documents for machinery), Part B. |

| The obligation to hand over the special documents on the incomplete machine to national authorities at a reasonable request. How the documents are handed over must also be specified in this obligation. The commercial protective rights of the manufacturer of the partly completed machine remain unaffected. |

| A note that the partly completed machine cannot be put into operation until, if applicable, it has been determined that the machine in which the partly completed machine is to be installed corresponds to the conditions of the Machinery directive. |

| Date and place of the declaration. |

| Information on persons authorized to issue this declaration in the name of the manufacturer or its authorized representative and the signature of this person. |

Use of work equipment directive 2009/104/EC

The Use of Work Equipment Directive 2009/104/EC contains the minimum specifications for safety and health protection with the use of work equipment. It addresses the operating company (employer) and in Chapter I includes the following articles:

|

|

|

| Article 3 | General obligations |

| Article 4 | Rules concerning work equipment |

| Article 5 | Inspection of work equipment |

| Article 6 | Work equipment involving specific risks |

| Article 7 | Ergonomics and occupational health |

| Article 8 | Informing workers |

| Article 9 | Training of workers |

| Article 10 | Consultation of workers and workers’ participation |

The directive regulates the obligations of the employer and logically requires that the employer ensures that safety and the protection of health are guaranteed with the operation of the work equipment provided. This includes inspection of the work equipment before first use and throughout the period of usage. The concrete practices must – unlike with single market directives – ultimately be regulated by the member state. Annex I, however, contains extremely detailed specifications, e.g.:

- on operation, commissioning and shutdown of the work equipment

- on protective devices and warning notices

- on maintenance and safe energy disconnection

- on mobile work equipment

The Use of Work Equipment Directive 2009/104/EC can be found in its original text at www.eur-lex.europa.eu

European standards

Harmonized European standards specify the basic requirements of the EU directives for safety and health protection as they are named, for example, in Annex I of the Machinery directive 2006/42/EC. According to Machinery directive, Article 5 (2), upon reaching the protection level of an applicable harmonized European standard, the corresponding requirement from the directive is simultaneously considered satisfied (i.e., the compliance with the corresponding directive).

Unlike directives and their national implementation in the national law of the Member States, standards are not legally binding. If other measures attain at least the level of protection described in (harmonized) standards, such measures are also possible. The difference between satisfying the requirements of a relevant harmonized standard and a solution that takes a different approach does, however, have consequences. The manufacturer must provide additional documentation that verifies compliance with the directive. Differences may also arise during the conformity procedure if there are deviations from (harmonized) standards or if no applicable (harmonized) standard is available.

The so-called presumption of conformity applies as soon as a harmonized European safety standard is published in the Official Journal of the European Union. This means that, by satisfying the protective objectives of this standard, it is assumed that conformity with the corresponding directive is ensured for this safety aspect.

Just like international ISO and IEC standards, European machine safety standards (EN…) can be divided into basic safety standards (type A standards), safety group standards (type B1 standards and type B2 standards) as well as machine-specific technical standards (type C standards).

The following table lists interesting European machine safety standards that are not available as an ISO or IEC standard:

| Type | European standard | Contents |

| C | EN 415-1 ... 10 | Safety of packaging machines |

| C | EN 528 | Rail dependent storage and retrieval equipment - Safety requirements for S/R machines |

| C | EN 618 | Continuous handling equipment and systems - Safety and EMC requirements for equipment for mechanical handling of bulk materials except fixed belt conveyors |

| C | EN 619 | Continuous handling equipment and systems - Safety requirements for equipment for mechanical handling of unit loads |

| C | EN 620 | Continuous handling equipment and systems - Safety requirements for fixed belt conveyors for bulk materials |

| C | EN 1010-1 ... 5 | Safety of machinery. Safety requirements for the design and construction of printing and paper converting machines |

| C | EN 1459-1 ... 5 | Rough-terrain trucks - Safety requirements and verification |

| C | EN 1672-1 | Food processing machinery - Basic concepts - Part 1: Safety requirements |

| C | EN 12622 | Safety of machine tools - Hydraulic press brakes |

| C | EN 16307-1 | Industrial trucks – Safety requirements and verification |

Other European standards (EN...) have been adopted from ISO and IEC standards on an European level. ISO standards adopted by CEN as European standards are given the designation EN ISO xxxxx. In the past, IEC standards were adopted as EN 6xxxx, i.e. without the addition of IEC unlike ISO standards. Since 2018-09, in accordance with the "Frankfurt Agreements" new standards have been given the designation EN IEC 6xxxx in the case of standards adopted by CENELEC. The designations of existing standards remain unchanged.

Note: Further standards can be found on the websites of the national standardization bodies or specialized publishers.

An overview of key ISO and IEC standards can be found in the section "International standardization":

Laws

Whereas EU regulations constitute direct law in the member states, EU directives have to be integrated into the national legislative system of each member country. The implementation of an EU directive is therefore slightly different in each member state. It can also comprise several laws and regulations. Even though the respective national laws and regulations form the legal basis of machinery laws in the member states, it often makes sense for the user to read the EU directives because the necessary information is presented there concisely in one document.

Germany

The implementation of the EU single market directives in Germany is divided into two parts. The Product safety act (ProdSG) serves as the basis for implementation of the General product safety directive 2001/95/EC.

Technical details of the EU directives are regulated in regulations, for example:

|

EU single market directive |

German regulation on the Product safety act (ProdSG) |

|

|

2006/42/EC |

Machinery directive |

9. ProdSG |

|

2014/35/EU |

Low voltage directive |

1. ProdSG |

|

2014/34/EU |

ATEX directive |

11. ProdSV |

|

2014/29/EU |

Pressure vessel directive |

6. ProdSV |

|

2014/68/EU |

Pressure equipment directive |

14. ProdSV |

|

2014/33/EU |

Lifts directive |

12. ProdSV |

|

2016/425/EU |

PSA directive |

8. ProdSV |

| 2014/30/EU |

EMC directive |

EMC law |

In Germany, sociopolitical EU directives are implemented by:

|

EU social directive |

German law |

|

89/391/EEC – Safety at work framework directive |

Arbeitsschutzgesetz ArbSchG (Act on occupational safety and health) |

|

2009/104/EC – Use of work equipment directive |

Betriebssicherheitsverordnung (Ordinance on industrial safety and health, BetrSichV) |

In addition, numerous other publications are available on the websites of the following institutions:

- Deutsche Gesetzliche Unfallversicherung (statutory German accident insurance association, DGUV)

- Bundesministerium für Arbeit und Soziales (German Federal Ministry of Labour and Social Affairs, BMAS)

- Bundesanstalt für Arbeitsschutz und Arbeitsmedizin (Federal Institute for Occupational Safety and Health, BAuA)

- VDMA

- ZVEI

Ordinance on Industrial Safety and Health

The Betriebssicherheitsverordnung (Ordinance on industrial safety and health, BetrSichV) essentially translates and concretizes the requirements of directive 2009/104/EC in German law. Extracts of the key requirements for operating companies are listed below:

§ 4 Basic obligations of the employer

(1) Work equipment may not be used until the employer

- has conducted a risk assessment,

- has taken the protective measures determined by the risk assessment such that they correspond to the state of the art, and

- has ascertained that use of the work equipment is safe in line with the state of the art.

(4) The employer shall ensure that work equipment, for which inspections are prescribed in § 14 and section 3 of this ordinance, is used only if these inspections have been conducted and documented.

(5) The employer shall check the effectiveness of the protective measures before the work equipment is used for the first time. Clause 1 shall not apply in cases where appropriate inspections in accordance with § 14 or § 15 were conducted. The employer shall additionally ensure that work equipment is checked before use by means of visual inspection and, where necessary, by means of a function check for obvious defects, and that protective and safety devices are subjected to a function check at regular intervals. Clause 3 shall also apply to work equipment for which recurring inspections in accordance with § 14 or § 16 are prescribed.

§ 14 Work equipment test

(4) The employer shall comprehensively check the work equipment named in Appendix 3 to ensure that it is in a safe condition and operates safely:

- before initial commissioning,

- before recommissioning following changes that require testing and

- on a recurring basis in accordance with the requirements named in Appendix 3.

With our Machine Safety Services we are able to offer operating companies expert advice, safety inspections before initial commissioning as well as safety inspections at regular intervals.

Substantial modification

Modifications to machines by the operating company or by a system integrator tasked to make modifications on behalf of the operating company can result in the operating company becoming the manufacturer of a new machine in cases where the machine is "modified substantially". When retrofitting safety technology it is therefore also necessary to check that:

- an increase in the safety level of the machine is achieved

- the machine does not perform any new functions

- the existing control is still appropriate for the new safety technology

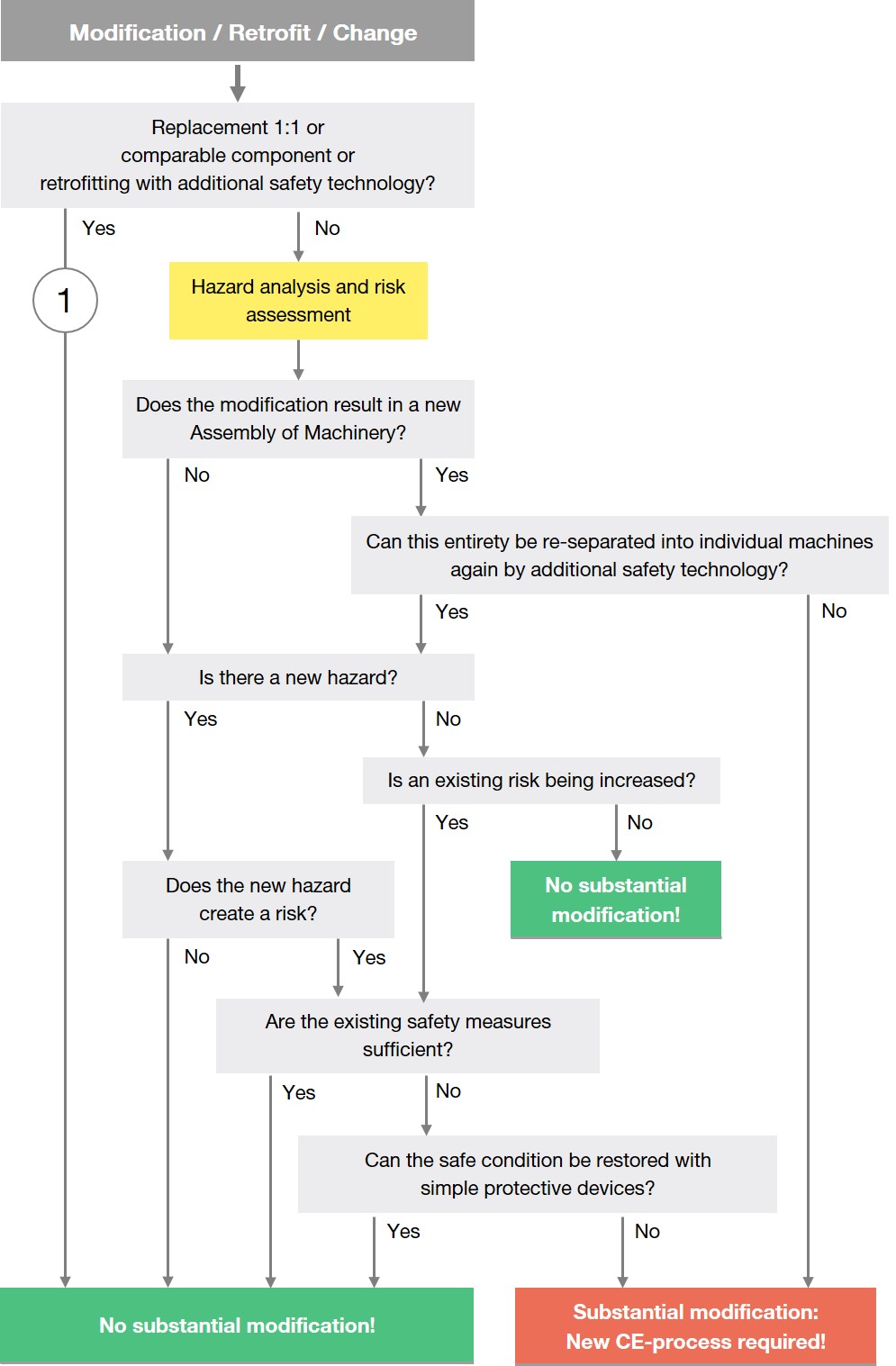

If this is the case, it can be assumed based on the interpretation paper "Substantial modification to machinery" from the Bundesministerium für Arbeit und Soziales (German Federal Ministry of Labour and Social Affairs, BMAS) from April 9, 2015, that no substantial modification has been performed and therefore that no manufacturer obligations with new proof of conformity exist. Otherwise the modified machine would have to be regarded as a new machine and undergo the entire CE process in accordance with the Machinery Directive. The correlation outlined in the interpretation paper is shown in the flow chart below:

Example: Measures that exclusively serve to increase the level of safety – e.g. retrofitting

or improving safety technology – do not constitute a substantial modification: see Case 1.