53C/ 55C series

New sensor portfolio for hygiene-sensitive production processes

53C and 55C series: Two new stainless steel series in a miniature housing for detection tasks in production and packaging processes

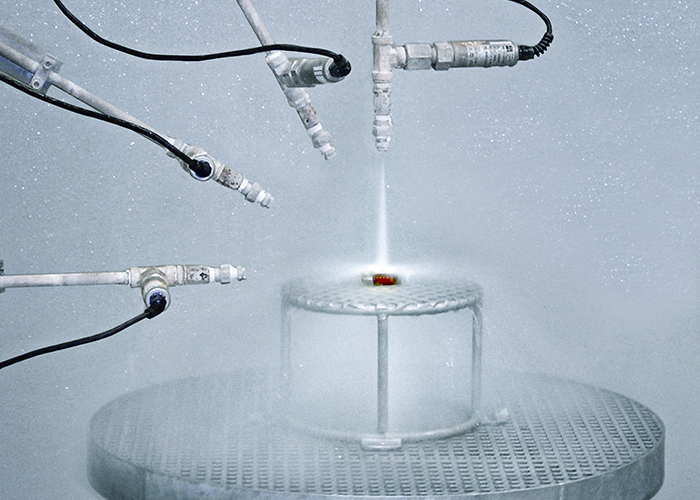

When processing, filling or packaging food or pharmaceutical products, very strict requirements apply with regard to the hygiene and cleaning of the systems.

Not only the production systems, but also electronic components such as sensors, must withstand regular intensive cleaning and disinfection cycles with sometimes aggressive cleaning agents. In particular, the use of sensors with a hygienic design in accordance with the DIN EN 1672-2 standard (“Food processing machinery - Basic concepts - General design principles”) is recommended for applications involving direct contact with food or for detection tasks above unpackaged products. These sensor solutions are characterized by a special design as well as high resistance to cleaning agents and tightness.

Our new stainless steel sensor platform with the 53C series in hygienic design and the 55C series in wash-down design was specially developed for applications with increased hygiene requirements. To withstand the harsh conditions, the housings of both sensor series are made of high-quality stainless steel V4A (AISI 316L). The smooth stainless steel surfaces (typical value ≤ 0.8 Ra) ensure that cleaning agents drip off immediately, preventing the spread of bacteria in production plants. During the design phase, great importance was placed on making both the glass-free optics cover and the operating elements absolutely tight and gap-free. All housing materials are FDA-compliant and approved for direct contact with food. This ensures additional safety in food processing and packaging.

Advantages for you

- Two full series with all operating principles: Throughbeam photoelectric sensors, retro-reflective photoelectric sensors and scanners for specific areas of application and tasks

- 2 housing designs for use in wet areas (wash-down) and hygienic areas (hygienic design)

- High-quality V4A (AISI 316L) stainless steel housing with smooth surface and glass-free optics cover made of PMMA+ with special scratch-resistant coating to prevent bacterial carryover

- IP69K rating for reliable functionality and absolute tightness of the housing

- Thermal and chemical resistance (tested and certified according to ECOLAB, CleanProof+, JohnsonDiversey)

- FDA-compliant housing materials enable the sensor to be used in applications with direct food contact

- Simple configuration and condition monitoring through IO-Link interface, as well as variants with electronic scanning range adjustment and measured value output via IO-Link

Highlights

All components of the stainless steel sensors have been specially developed for use in hygiene-sensitive areas. The conditions here are harsh, especially for electronic components. Regular cleaning of the systems with high-pressure cleaners and aggressive cleaning agents plays a significant role. In addition, the change between productive and cleaning shifts results in large temperature fluctuations, which must not affect the functionality of the sensors.

- The stainless steel housings made of V4A (AISI 316L) are absolutely dust- and waterproof and achieve protection ratings of IP67, IP68 and IP69K

- Particularly smooth stainless steel surfaces with around 0.8 Ra prevent bacterial carryover

- The glass-free optical cover (scratch-resistant and diffusion-tight plastic (PMMA+) with an indium protective layer) withstands tough cleaning cycles and ensures reliable operation

- The newly developed control element is completely sealed and gap-free

- All materials are approved for direct food contact (FDA-compliant)

- Chemical and thermal resistance, tested and certified by ECOLAB, CleanProof+ and JohnsonDiversey

The 55C series in wash-down design is suitable for use in the wet area of production lines. The special design allows the entire system to be thoroughly cleaned with all common agents and methods. The diffusion-tight and chemically resistant materials of the optics and operating elements, in combination with the gap-free construction, prevent bacterial carry-over. The closed housing technology and the extended temperature range guarantee that the systems will function properly for years.

The 53C series sensors are designed for use in hygienically sensitive areas, such as the pharmaceutical, cosmetics and food industries.

Based on the 55C series in its basic elements, this special development is even more consistently geared towards preventing bacterial carry-over in its housing design. The smooth housing contours without mounting holes reduce any deposits. The unique mounting concept ensures a gas-tight connection between the sensor and the machine via the mounting spigot.

The two sensor series in a miniature stainless steel housing include all operating principles: throughbeam photoelectric sensors, reflective photoelectric sensors and photoelectric proximity sensors. Various models have been developed for special areas of application and solve challenges in production and packaging processes in a customized, reliable and economical way.

Our product highlights for special applications:

- Retro-reflective photoelectric sensors for glass and PET detection or film detection

- Laser retro-reflective photoelectric sensors for small parts detection

- Throughbeam photoelectric sensors for detecting watery liquids and for fill level control

- Scanners with background suppression and small light spot for detecting shiny and color-structured objects

- Scanners with background suppression and elongated line light spot for detecting transparent objects as well as objects with openings, holes and cutouts

- Sensors with background suppression and electronic scanning range adjustment; measured value output via IO-Link

- Sensors with background suppression and special V-optics for detecting transparent, planar, reflective, and high-gloss objects, as well as the top layers of syringe or ampoule trays

The 55C and 53C series sensors are equipped with an IO-Link interface, which makes it possible to implement innovative machine concepts with remote maintenance, diagnostics or sensor configuration. The sensors can be parameterized, operated and maintained (condition monitoring) via IO-Link. Format changes are also much more flexible and economical with IO-Link.

Special scanner variants are electronically adjustable and equipped with a measured value transmission for monitoring a specific window area. The scanning range can be set numerically via IO-Link (Remote Set Distance). The device calibration enables high accuracy during remote adjustment. When replacing a defective sensor, the default settings can be transferred to the new device via IO-Link without any loss and without having to repeat the teach-in process.

Cables and reflectors for hygienic applications

Our range of 55C and 53C series sensors for applications in the food and pharmaceutical industry is complemented by a range of suitable cable solutions and reflectors.

The special connection cables are made of FDA-compliant materials (thermoplastic elastomers (TPE) and V4A stainless steel) and are therefore approved for direct contact with food.

If the cables are mounted with a tightening torque of 0.4 Nm or 0.6 Nm, they achieve an IP69 rating. This means that the cable solutions prevent the ingress of liquids, dust or steam and can withstand intensive cleaning processes with high-pressure cleaners. ECOLAB certification confirms the cables' resistance to aggressive cleaning agents. The cables can be used in a temperature range from -40°C to +105°C.

The cable portfolio for use in hygienically demanding industrial areas includes M8 and M12 as well as cable lengths of 2, 5 and 10 meters.

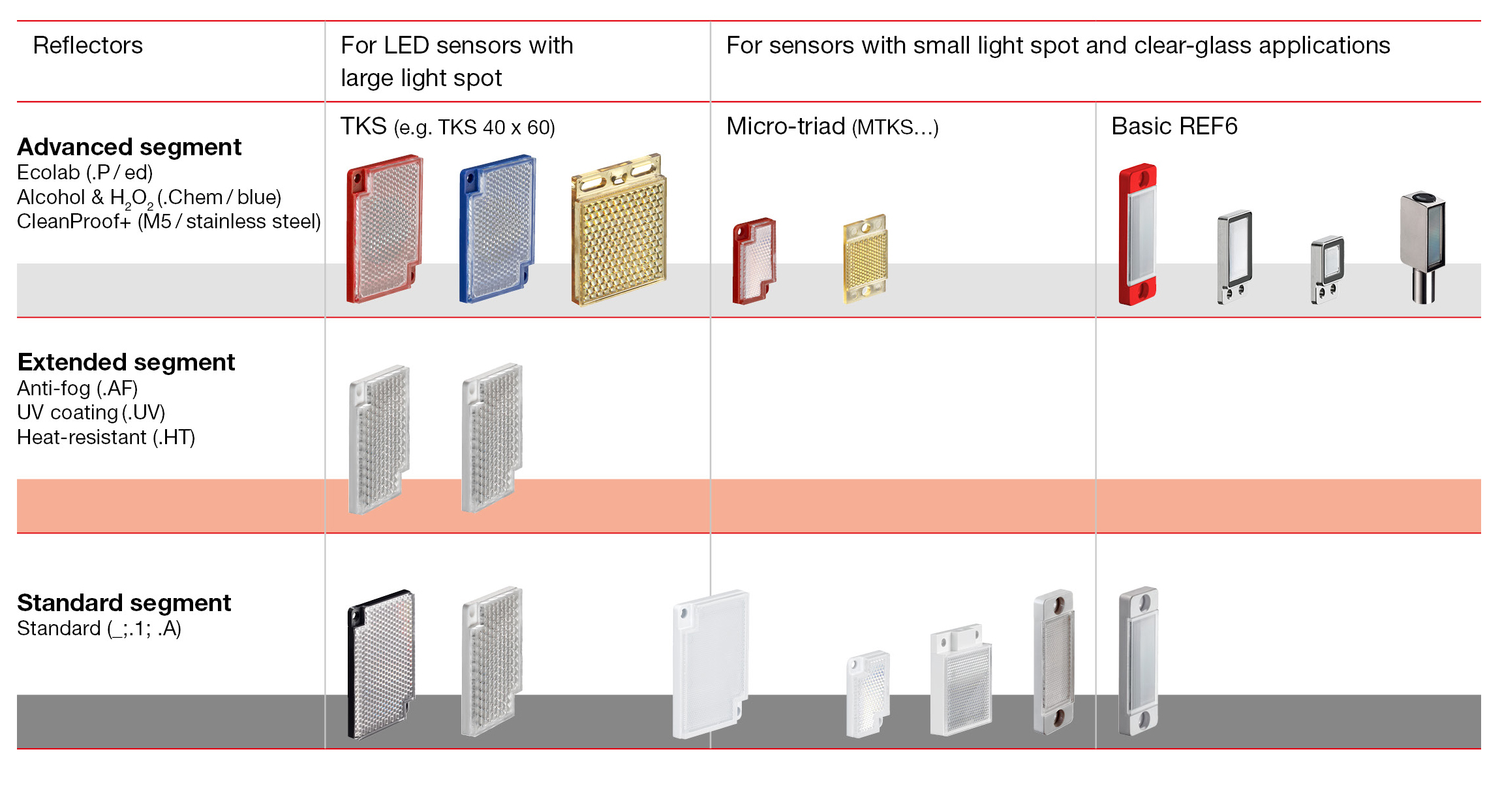

Reflectors

Just how reliably retro-reflective photoelectric sensors can detect depends upon the selected reflector, among other things. We offer reflectors with plastic or stainless steel housings as well as reflective tapes for different requirements: Reflectors in the advanced segment are often used in the food and pharmaceutical industry on account of their resistance against cleaning agents. The Solidchem reflectors made of chemically resistant plastic also stand out for their high temperature resistance. The reflectors from the extended segment are suitable for production areas with high air humidity or large differences in temperature.

Application

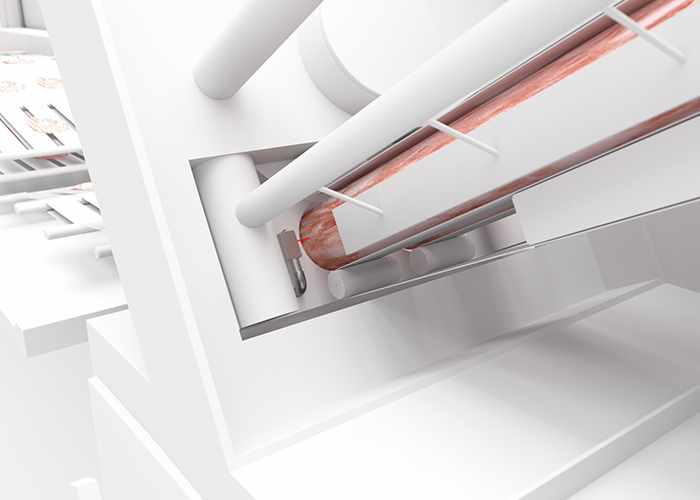

Monitoring the loading of a sausage slicer

Requirement:

In the food industry, sausage is delivered in large bars and sliced into fine slices in a slicing machine. The product in the machine feed must be reliably detected so that the gripper can push the material evenly towards the blade and all the cut slices have the required thickness.

Solution:

Our HT53C.S photoelectric proximity switch in hygienic design reliably monitors the product feed to the sausage cutting machine. If there is enough material for the machine to operate, the system starts up automatically. The particularly small light spot is characterized by excellent performance, especially with objects of different colors, while the sensor's background suppression ensures reliable color-independent product detection.

Detecting the front edge of products being cut

Requirement:

In an industrial cutting machine, products are cut into small stacks and pre-portioned into trays for later packaging. The challenge for the sensor system is that the front edge of the sliced goods must be reliably detected at the same switching point, regardless of whether they are on the conveyor belt with a slight lateral offset. The sensors are mounted directly above the conveyor belt. In this application, it must be ensured that no cleaning agent residues drip onto the cheese or the sliced goods.

Solution:

The HT53CL1.X photoelectric proximity switch with background suppression is optimized for detecting the front edges of products with a long laser light spot. Thanks to the line light spot, sliced products are reliably detected at the same switching point even if they are offset to the side on the conveyor belt. This ensures that the cut goods are neatly positioned when loaded into the tray packaging and ensures that the edge of the tray does not come into contact with the food and that traces of grease do not affect the subsequent hygienic welding of the tray. The 53C series housing is designed without drill holes for hygienic applications and is suitable for areas of application with direct food contact.

Fill level detection when bottling liquids

Requirement:

In the beverage industry, a filler is used to fill water into 3-liter bottles. The fill level must be exactly the same for all bottles – underfilling must be prevented. Reliably detecting the fill level of aqueous liquids in any container is one of the most challenging detection tasks for sensors and requires particularly powerful sensor solutions.

Solution:

The LS55C.H2O and LE55C.H2O through-beam photoelectric sensors have been developed for detecting aqueous liquids and for fill level control, and reliably stop the filling process. The 55C Series stainless steel transmitter and receiver system in a wash-down design has a high transmission capacity and can also be used with colored containers and containers with plastic labels.

This solution can replace an expensive filling control system, such as a scale or a flow meter, and is easy to set up: No further settings are required via a control element other than the exact alignment of the optical axis.

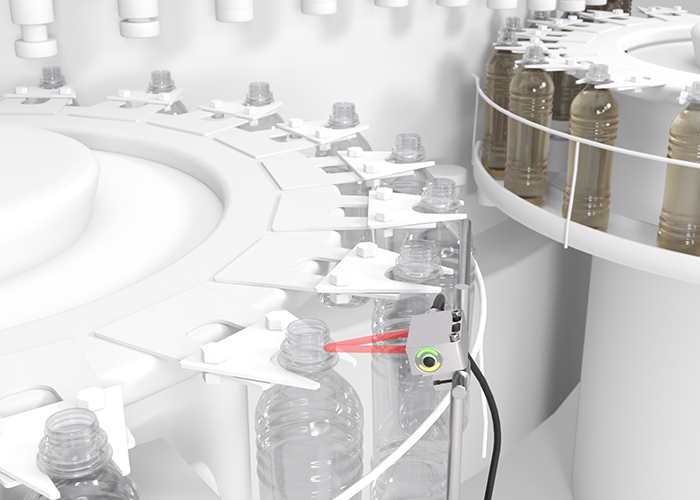

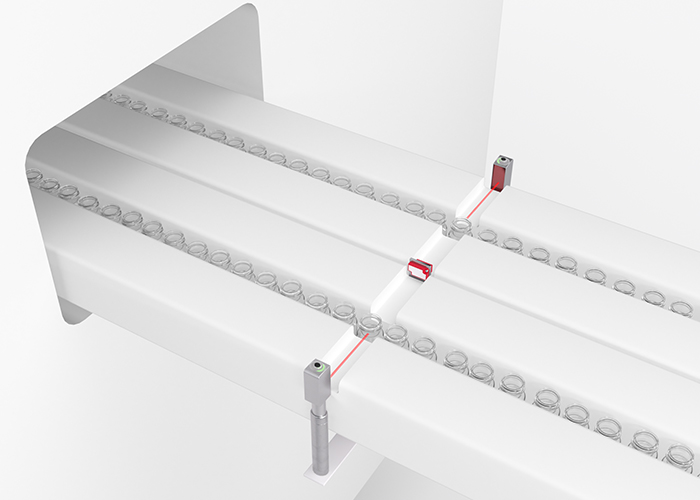

Presence checking in bottle filling in the transfer star

Requirement:

Bottle filling is characterized by very high speeds. To ensure a smooth process, it must be ensured before filling that all positions of the transfer star are occupied by bottles.

Solution:

The HT55C photoelectric proximity switch with background suppression detects containers in the bottle filling reliably and without a reflector. The sensors are designed for wet areas and can withstand intensive cleaning processes. ECOLAB certification and our extended CleanProof+ cleaning agent long-term test ensure the reliable functionality of the sensor even under harsh conditions.

Bottle detection during transport

Requirement:

In a filling plant for milk bottles, the position of the bottles on the conveyor belt must be reliably and precisely detected for the further packaging steps in the plant.

Solution:

The PRK55C.TT3 retro-reflective photoelectric sensor also reliably detects transparent containers. The sensitivity can be set using the teach button. An integrated tracking function automatically compensates for soiling on the reflector or sensor. This extends the cleaning intervals and reduces system downtime. The stainless steel housing in a wash-down design with the highest degree of protection, IP69K, is very robust. Resistance to the cleaning agents commonly used in the market is confirmed by ECOLAB certification, the Leuze CleanProof+-Test and tests according to JohnsonDiversey.

Precise positioning of vials

Requirement:

Vials made of transparent glass must be precisely detected and positioned for the filling of vaccines and other liquids.

Solution:

The retro-reflective photoelectric sensor PRK53CL1.T3 with a small laser light spot, in combination with a small stainless steel reflector, enables highly precise detection and positioning of vials. The sensor in its miniature housing can be easily integrated even in confined spaces. Both the sensor and the reflector are designed for hygienic applications.

Detection and positioning of transparent vials

Requirement:

In a pharmaceutical packaging plant, vials are filled on multi-track packaging lines. The position of the transparent vials must be precisely detected before filling. One challenge is that the vials are very flat and the photoelectric sensor must aim precisely at the reflector.

Solution:

Our 53C series PRK53C.T3 retro-reflective photoelectric sensors are used in this application with MTKS 14x23.P pharmaceutical micro triple reflectors specially developed for the pharmaceutical industry. The hygienically designed stainless steel sensors precisely target the reflector and ensure reliable detection of the vials.

Overview of our stainless steel sensors

|

Parameter |

PRK53C / PRK55C |

LS/LE53C / LS/LE55C |

HT53C / HT55C |

ODT53C /ODT55C |

|

Function principle |

Retro-reflective photoelectric sensor |

Throughbeam photoelectric sensor |

Diffuse reflection photoelectric sensor with background suppression |

Distance sensor with background suppression |

|

Housing design and dimensions (W x H x D) |

Series 53C: Hygienic design (14.0 x 35.4 x 20.4 mm) Series 55C: wash-down design (14.0 x 35.4 x 25.0 mm) |

|||

|

Housing material |

Stainless steel V4A (AISI 316L) |

Stainless steel V4A (AISI 316L) |

Stainless steel V4A (AISI 316L) |

Stainless steel V4A (AISI 316L) |

|

Light sources |

Red light (645 nm) Laser red (650 nm; laser class 1) |

Red light (645 nm) Infrared (1450 nm) |

Red light (645 nm) Infrared (860 nm) Laser red (650 nm; laser class 1) |

Red light (645 nm) |

|

Switching frequency |

1,500 Hz (red light) 3,000 Hz (red laser) |

1,000 Hz (red light) 350 Hz (infrared) |

1,000 Hz (red light & infrared) 3,000 Hz (red laser) |

750 Hz (red light) |

|

Operating range |

0.1 … 5 m (Zweilinser) 0 … 4 m (Autocollimation) 0 … 3 m (Detection of transparent objects) 0 … 2 m (Laser: Autocollimation) 0 … 0.4 m (Laser: Detection of transparent objects) |

0.05 … 8.5 m (Red light) 0 … 64 m (Infrared) |

5... 600 mm (infrared) 5... 450 mm (red light) 5... 200 mm (small light spot) 5... 100 mm (long light spot) 15... 400 mm (laser) |

10... 150 mm 10... 80 mm (small light spot) |

|

IO-Link |

V1.1 (COM2) |

V1.1 (COM2) |

V1.1 (COM2) |

V1.1 (COM3) |

|

Operation |

Teach button |

- |

multi-turn spindle |

Teach button |

|

Temperature range |

-40 … +70°C |

-40 … +70°C |

-40 to +70°C |

-40 to +70°C |

|

Protection class |

IP 67, IP 68, IP 69K |

IP 67, IP 68, IP 69K |

IP 67, IP 68, IP 69K |

IP 67, IP 68, IP 69K |

|

Certifications |

CE, UL, ECOLAB, CleanProof+, JohnsonDiversey |

CE, UL, ECOLAB, CleanProof+, JohnsonDiversey |

CE, UL, ECOLAB, CleanProof+, JohnsonDiversey |

CE, UL, ECOLAB, Clean-Proof+, JohnsonDiversey |

|

Connection |

M8, cable, cable pigtail M12 |

M8, cable, cable pigtail M12 |

M8, cable, cable pigtail M12 |

M8 |