RDH 200

Flexible use: RDH 200 series RFID readers

Compact with a reading range of up to 100 mm

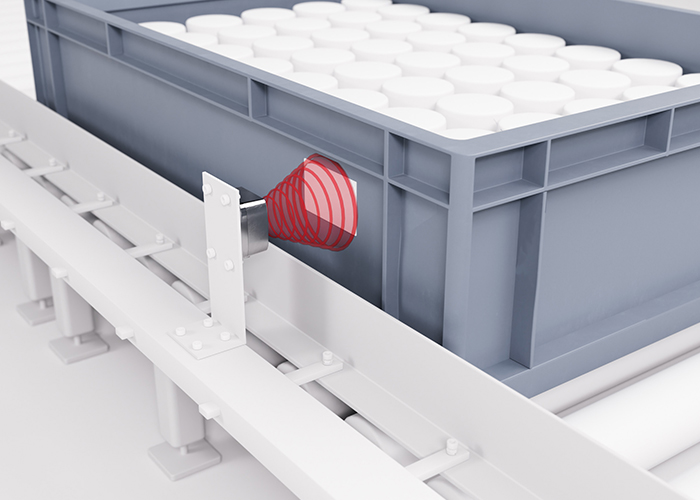

Modern identification systems such as RFID are an indispensable component of automated production control systems for seamless production process tracking and efficient material flow monitoring.

Space is often limited, particularly in production cells and on conveyor lines. The high-frequency readers in the RDH 202/242 series stand out for their compact dimensions, can be mounted very easily and flexibly thanks to their design, and still offer a wide range of applications with a reading range of up to 100 mm.

The new RFID readers are available as RDH 242 with IO-Link or as RDH 202 with RS 232 interface.

The highlight of this RFID series is its suitability for NFC applications: Besides the RFID industry standard ISO 15693, RDH 202/242 also supports ISO 14443A and reads and writes RFID tags in accordance with NFC Forum Types 2 and 5. This means that the readers can also be used for authentication on machines via NFC tags, for example.