Compact scanner

DCR 100i

The DCR 100i series code reader is developed for industrial requirements and enables fast and accurate capture of 1D and 2D bar codes. Thanks to its simple commissioning, intuitive software and powerful decoding algorithms, it can be seamlessly integrated and ensures reliable reading in any environment.

Advantages for you

- Reliable code reading with the 1.3 MP CMOS imager

- Flexible reading distances within the reading field thanks to manually adjustable focus

- Supports reading of DPM codes

- Easy setup thanks to integrated trigger and teach buttons

- Compact, robust design with protection class IP64

Highlights

The DCR 100i’s adjustable focus within the reading field allows it to adapt to different distances, code sizes and surfaces, ensuring sharp images, high reading rates and scalable performance in any application.

Four focus areas and typical reading distances:

- HHD (hyper high density – very short operating range): 40-120 mm, at module width 0.08 – 0.18 mm

- HD (high density – short operating range): 60-300 mm, at module width 0.08 – 0.33 mm

- SR (standard range): 70-460 mm, at module width 0.127 – 0.33 mm

- LR (long range): 70-550 mm, at module width 0.127 – 0.33 mm

The DCR 100i includes an automatic mode that adjusts exposure, illumination, and decoding settings directly on the device – no PC required – ensuring fast, accurate, and reliable reading in any environment.

The DCR 100i series provides Ethernet connectivity and supports industrial protocols – including Modbus and TCP/IP – as well as RS 232, ensuring seamless integration with any automation system.

Application

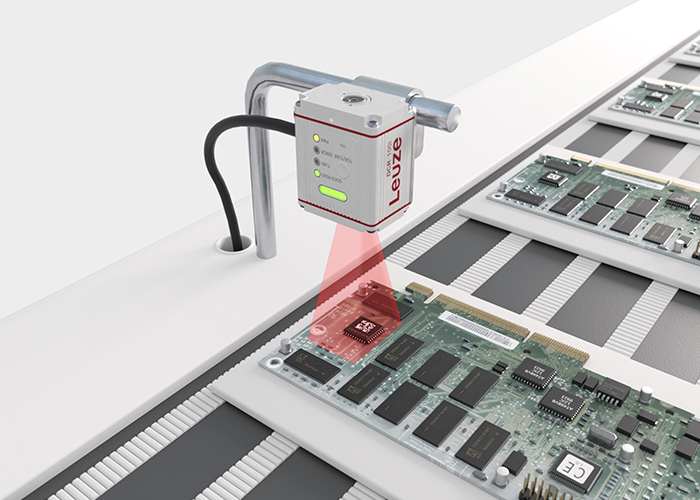

Precise reading of DPM codes on electronic components

Requirement:

In the electronics industry, reading small, sophisticated DPM codes on integrated circuits (ICs) and printed circuit board assemblies (PCBAs) is critical for traceability and quality control.

Solution:

The DCR 100i code reader features DPM decoding and a manually adjustable focus, enabling reliable capture of small codes.

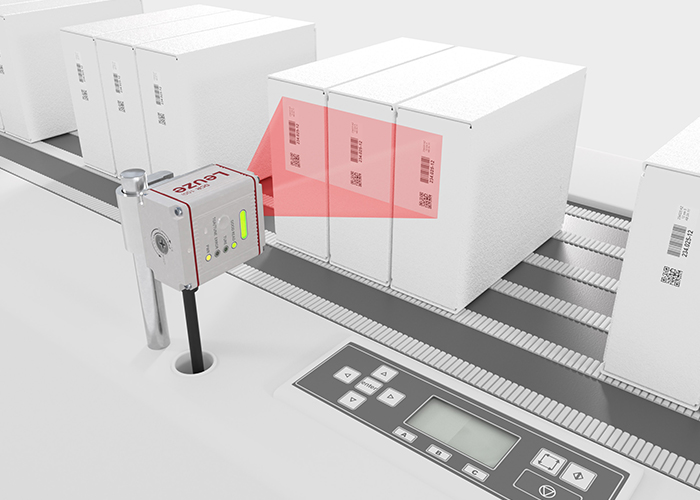

Multiple code reads on packaging

Requirement:

Each secondary packaging box is labeled with both a 1D and a 2D code. For quality assurance purposes, both codes should be read together in a single scanning process before the box group is packaged.

Solution:

The DCR 100i code reader can read multiple bar codes and 2D codes on packaging simultaneously. Its imager is optimized for vertical mounting and provides a wide horizontal field of view as well as optimized reading rates.

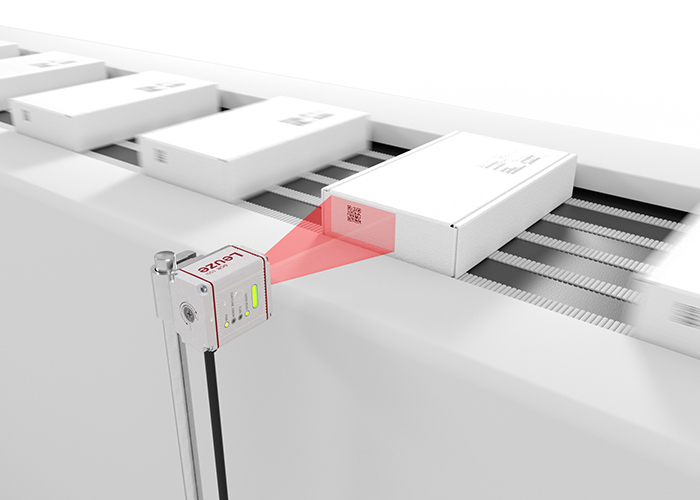

Precise code reading on moving packaging

Requirement:

In the packaging industry, accurate reading of codes on moving boxes is essential. All code orientations and types must be accounted for to ensure reliable tracking and quality control.

Solution:

The DCR 100i is equipped with an imager that scans 120 frames per second (conveyor speed up to 2 m/s) and powerful integrated illumination.It captures barcodes on moving objects quickly and accurately, reducing reading errors and increasing throughput in demanding applications.

Technical features

| Overview | |

| Optical data | |

| Imager | CMOS (Global Shutter) |

| Resolution | 1080 * 1280 (1.3 megapixels) |

| Frame rate | 120 fps |

| Decoding speed | Continuous reading mode: < 1m/s Trigger mode: < 2 m/s |

| Reading range | 40–550 mm |

| Field of view | 29° (H) x 34° (V) |

| Light source | LED, red |

| Laser class | Laser class 1 (IEC 60825-1:2014), red |

| Electrical data | |

| Supply voltage | 12–28 V |

| Operating current | 500 mA ±10% (typical), 1000 mA ±10% (max.) |

| Interfaces | Ethernet TCP/IP/Modbus TCP, RS232 |

| Digital input | 1 x trigger input |

| Switching output | 2 x output (good read / no read) |

| Cable connection | • Single plug 0.3 m cable with M12 12-pin A-coded (socket) • Double plug 0.3 m cable with

|

| Mechanical data | |

| Dimensions | 44 (W) × 53 (D) × 29 (H) mm |

| Lens cover material | Glass |

| Metal housing | Aluminum |

| Fastening | 2 x M3 thread |

| Mounting device | BT DCR 100 |

| Protection class | IP 64 |

DCR 200i

Your benefit

- Easy and fast commissioning: A wizard integrated in the WebConfig tool guides you quickly and easily through the setup process and simplifies commissioning. For simple applications, the DCR 200i can also be set up for the reading task without a PC using just two buttons on the device

- Codes can be read on various materials: Interfering reflections can be reduced thanks to exchangeable polarization filters and diffusor foils

- Detection, even at high object speeds: High reading performance and powerful LED illumination enable a good reading result even at high object speeds or partially damaged codes.

- Attractively priced thanks to modular structure: Thanks to its modular structure, the DCR 200i can be customized exactly to the requirements of your application in terms of functional scope and performance.

Highlights

Seamless traceability of your products from production to the customer is becoming increasingly important. Whether for allergen management with food products, placement inspections in the pharmaceutical industry, shipping label monitoring in the packaging sector, or testing product quality in the electronics industry – the fast and reliable identification of 1D- and 2D-codes is essential.

The DCR 200i dual code reader combines simple handling with high reading performance – even with demanding reading tasks – and thereby provides support with:

- Identification – ensuring that the label was printed with product, bar code and/or data matrix code

- Track and trace – traceability of ingredients and packed products during production.

Applications

Code reading in the production area

Requirement:

In final assembly, codes are used for the traceability of individual components. These have to be read on a conveyor line, sometimes at high speeds.

Solution:

Thanks to their high scanning rate, the DCR 200i 1D-/2D-code readers enable the reading of codes on quickly moving objects. In addition, optics models are available for various reading ranges.

Code checking in electronics production

Shipping label inspection in conveyor and storage systems

Code inspection on pharmaceutical packages

Label inspection in the food industry

LSIS 220

The LSIS 220, with its optimized optics and resolution, offers large function reserves for reliable code reading, even while in motion. It quickly and reliably detects bar codes, stacked codes and 2D-codes.

Your benefit

- Improved optics for larger reading field and in-focus detection all the way to the edge areas, optimized resolution of 844x640 pixels for fast code reading

- Detection of 2D-codes, stacked codes and bar codes

- RS 232 or USB interface

- Switching input (trigger)

- Trigger button for manual activation and parameterization

- Construction without mechanically moving parts, robust metal housing with glass pane and protection class IP 65 make the devices very well suited for industrial use

- Extremely small design size, for installation even in difficult conditions

Applications

Manual code reading and code reading in presentation mode

Requirement:

In assembly processes where large, different components are moved manually, code reading must be possible both automatically and manually.

Solution:

The LSIS 220 1D-/2D-code readers are equipped with various trigger options for automatic and manual operation.

Article list

- Series: DCR 100i, DCR 100i

- Interface: RS 232, Ethernet

- Switching principle: Opto-coupled transistor, Opto-coupled transistor

- Code types, readable: Code 32, 2/5 Hong Kong, 2/5 IATA, 2/5 Interleaved,...

- Series: DCR 100i, DCR 100i

- Interface: RS 232, Ethernet

- Switching principle: Opto-coupled transistor, Opto-coupled transistor

- Code types, readable: Codabar, 2/5 Hong Kong, 2/5 IATA, 2/5 Interleaved,...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, PROFINET, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: UPC, 2/5 Interleaved, Aztec, Codabar, Code 128, Co...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, RS 422, EtherNet IP, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: EAN 8/13, 2/5 Interleaved, Aztec, Codabar, Code 12...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar, 2/5 Interleaved, Aztec, Codabar, Code...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, PROFINET, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Code 32, 2/5 Interleaved, Aztec, Codabar, Code 128...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Codabar, 2/5 Interleaved, Aztec, Code 128, Code 32...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, PROFINET, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Code 39, 2/5 Interleaved, Aztec, Codabar, Code 128...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar Stacked, 2/5 Interleaved, Aztec, Codab...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, PROFINET, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar Stacked, 2/5 Interleaved, Aztec, Codab...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, RS 422, Ethernet, OPC-UA

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Pharma Code, 2/5 Interleaved, Aztec, Codabar, Code...

- Series: DCR 200i, DCR 200i

- Interface: RS 232, RS 422, Ethernet

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Code 128, 2/5 Interleaved, Aztec, Codabar, Code 32...