Access guarding at pallet grouper / ungrouper

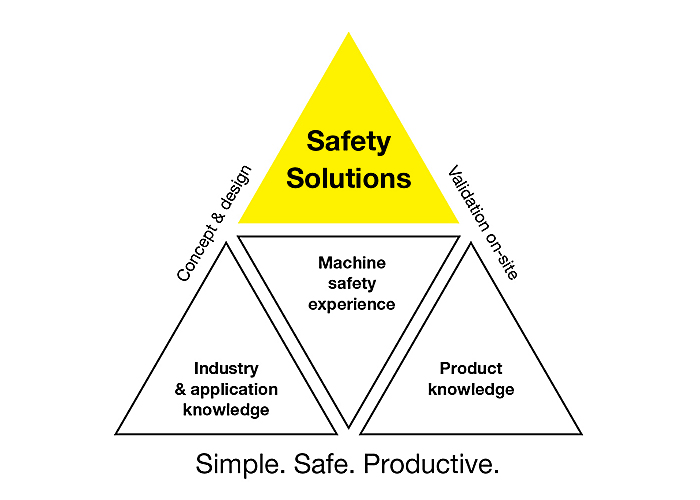

From risk assessment to validation: our safety solutions provide complete solutions for your systems. Our expert teams’ innovative safety concepts ensure efficient material flow, gapless safety and high availability of your system. Even in applications where classic concepts are pushed to their limits. Always with legal certainty, CE certification and compliance with standards. This makes implementation particularly easy for you.

When corridor supply vehicles, such as forklift trucks, are working at a transfer station to a danger zone, it is important that access guarding can reliably differentiate between a forklift truck and personnel. Common safety concepts often have limited options and require significant structural or procedural changes to ensure safe operation. In practice, this may result in compromises with correspondingly high residual risks, as well as a high degree of individual responsibility and discipline on behalf of the instructed operating personnel. For example, safety gaps may occur next to the forklift truck during transfer, the system may need to be operated at reduced speed during approach, or the system may need to be shut down entirely during the transfer.

Our safety solution meets all requirements with respect to gapless safety and efficient processes. Its safety concept is designed for manually operated forklift trucks, based on the revised standard EN 415-4 and does not require any operator intervention.

Requirement:

Pallet groupers/ungroupers must be guarded against access by persons. This requires reliable distinction between persons and the manually operated forklift trucks. To simplify the workflow and to minimize interruptions, an automatic system restart must be possible.

Solution:

Access to the danger zone is guarded by a multiple light beam safety device. A sensor for detecting the forklift truck is installed behind this. By evaluating the sensor signals and their sequence, the safety system distinguishes between forklift trucks and persons. Automatic restart is possible.

Operating principle:

When the safety light curtain is triggered, the work process of the (un)grouper is initially interrupted – irrespective of whether this is caused by a forklift truck or a person. If, however, the additionally installed radar sensor detects the presence of a forklift truck and the forklift truck correctly executes the expected process sequence, the safety system initiates automatic restart of the work process.

Advantages for you

- Optimum system utilization through automatic restart of the system without manual operator intervention

- High reliability and availability with optimum manipulation protection

- No components need to be installed in the floor

- Low service costs

- Simple integration in the safety circuit of the primary control

System components and safety parameters

| Safety sensors: MLD 500 multiple light beam safety device with device columns for floor mounting |

|

| Sensor for process monitoring: Radar sensor | |

| System control: MSI 400 safety control | |

| Leuze safety program | |

| PL d in accordance with EN ISO 13849-1, SILCL 2 in accordance with IEC 62061 | |

| 2-channel safety output |