Travel path safeguarding for crossing transfer cars

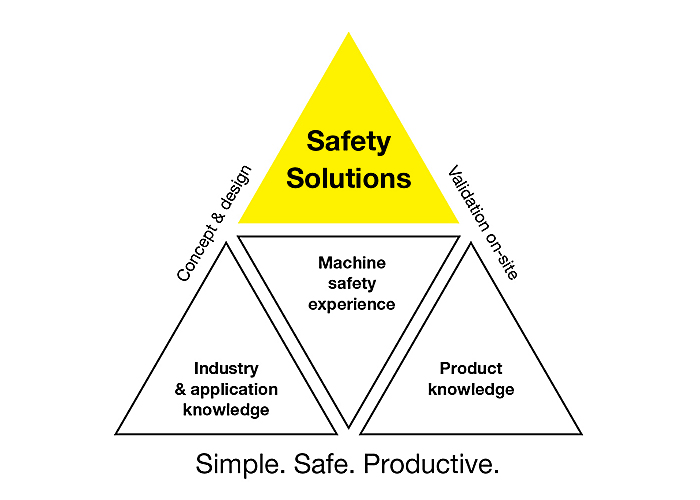

From risk assessment to validation: our safety solutions provide complete solutions for your systems. Our expert teams’ innovative safety concepts ensure efficient material flow, gapless safety and high availability of your system. Even in applications where classic concepts are pushed to their limits. Always with legal certainty, CE certification and compliance with standards. This makes deploying them extremely easy for you.

If the travel paths of rail-bound transfer cars cross, all movements during the travel process need to be taken into consideration when creating the safety concepts. Even the necessary safety functions need to be considered holistically – before the release of travel, during travel and upon reaching the final position. If the necessary functions for area guarding are integrated in the transfer car itself, this can have a considerable influence on the design of the car. In addition, this requires an exact, on-board position determination. Our safety solution offers an autonomous alternative for these applications. It ensures gapless area guarding while simultaneously providing maximum process reliability.

Requirement:

The transfer car crosses the travel path at regular intervals. During the entire movement, the relevant part of the travel path is to be safeguarded against the entry of persons. The transfer car must, however, be able to pass through the monitored area fully automatically.

Solution:

The relevant part of the travel path is safeguarded by safety laser scanners. These use their protective fields to detect the entry and presence of persons. During the travel process, the outline of the car is dynamically blanked out of the protective fields. The entire area thereby remains optimally protected at all times.

Operating principle:

With their protective fields, the safety laser scanners protect the part of the travel path in which the transfer car moves. They simultaneously detect the presence of persons and the position of the car in the monitored area. During travel, the safety system uses this information to blank out the outline of the car by changing over the protective fields from the monitored area. The monitored area is thereby fully protected and the safety level is maintained during the entire process.

Advantages for you

- Monitoring for the entry and presence of persons

- Gapless safety during the entire process

- No restrictions during parts transfer – even parts that protrude are possible

- Autonomous system with simple integration in the safety circuit of the primary control

System components and safety parameters

| Safety sensor: RSL 400 safety laser scanner | |

| System control: Siemens SIMATIC S7 | |

| Leuze safety program | |

| PL d in accordance with ISO 13849-1, SILCL 2 in accordance with IEC 62061 | |

| 2-channel safety output |