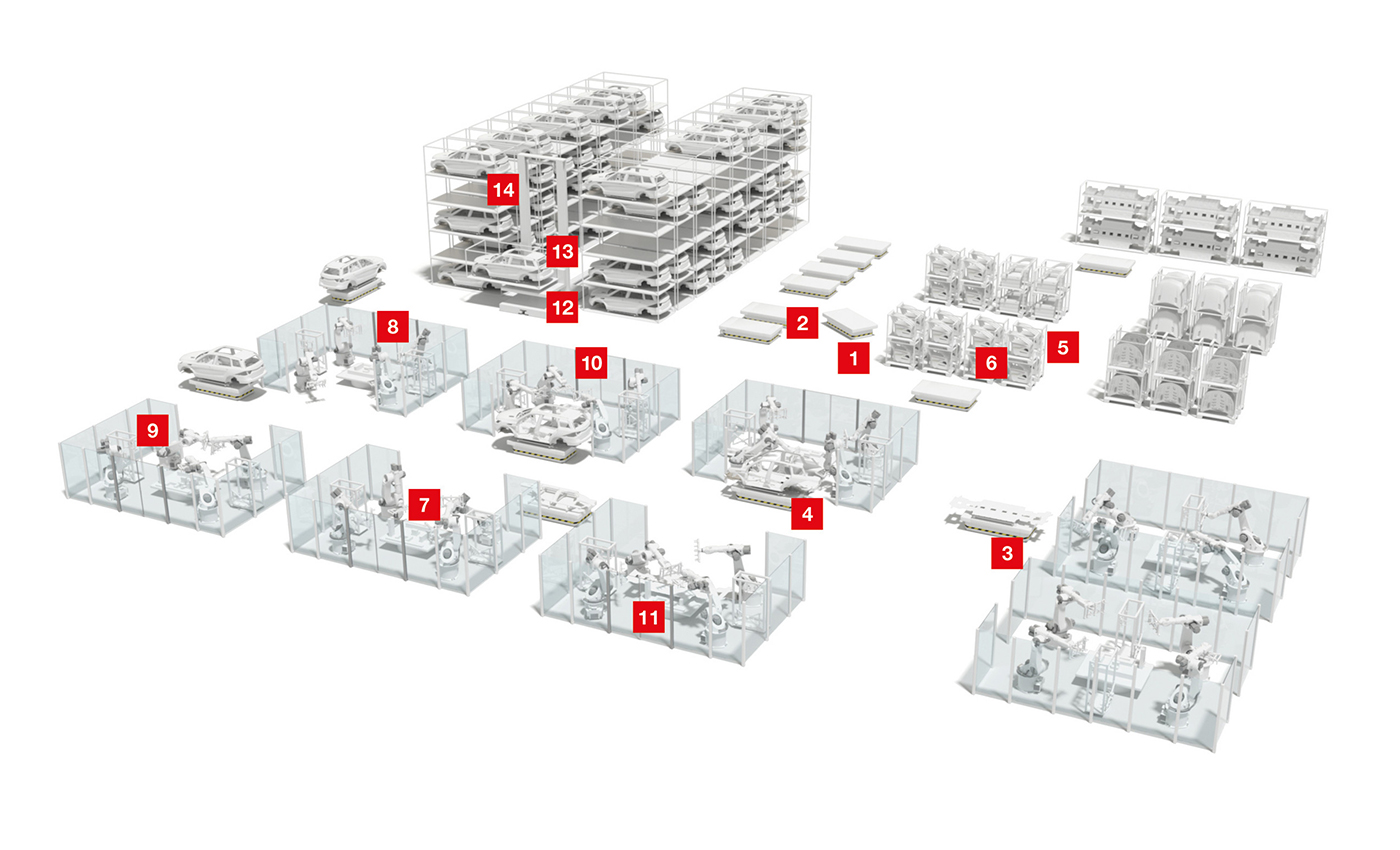

The body shop

Hundreds of individual parts are assembled to form a vehicle body.

Vehicle body construction is the most automated part of automobile manufacturing. Welding, flanging and lasering as well as riveting and screwing and – increasingly – gluing are typical work processes. Robot cells, collaborative robots and conveyor systems such as skids or electrical monorail systems determine the processes.

The factory of the future is characterized by even more flexible manufacturing concepts. A large variety, just-in-time material provision and the cushioning of peak demand are required. Storage areas and production are separated. Assembly occurs in flexible cell structures. In between, automated guided vehicles (AGV) transport materials.

Our sensors are used for a wide range of applications in the body shop. Safety laser scanners safeguard AGVs and supply data for their navigation. Sensors for presence and position control ensure smooth processes and our safety sensors guarantee the necessary machine safety.

Overview

Requirement:

The transportation path of the AGV must be guarded by means of safety sensors. The protective fields are to be flexibly adapted to the movement and loading situation. If the principle of natural navigation is used, the device is at the same time to provide the measurement data for the navigation software.

Solution:

The RSL 400 safety laser scanners merge safety technology and high-quality measurement value output in a single device. It has a scanning range of 270° and 100 reversible field pairs. Two scanners therefore provide optimum guarding of the AGV. The measurement data has a high angular resolution of 0.1° and a low measurement error.

Requirement:

An AGV must move safely and efficiently through its surroundings. Often, however, expansive production and storage areas pose a challenge. Moreover, many sensors are unsuitable for integration in flat vehicles due to their dimensions.

Solution:

A high-contrast track on the floor defines the route for the AGV. The OGS 600 optical guidance sensor uses edge detection to detect the line and sends control signals to the vehicle's drive. Its minimum distance from the floor is just 10 mm.

Requirement:

Access to the storage area is to be safeguarded by optoelectronic safety sensors without hindering free movement within the working range.

Solution:

The RSL 400 safety laser scanner is installed above the access area and the protective field is aligned vertically. This ensures that the working range is not affected. By means of two independent protective functions, an RSL 400 can simultaneously monitor two access points. Network integration is performed easily via PROFINET/PROFIsafe interfaces.

Requirement:

The material supply must be ensured at all times during operation. If a part in the warehouse runs out, parts are then removed from a nearby location and replenishing is requested. The fill level of the warehouse is to be monitored continuously, and the sensor system must work reliably in the present mechanical/spatial conditions over longer distances.

Solution:

The ODS 10 or – for higher resolutions – the ODKL 96 measuring sensors and the switching sensors of the HT 10 series provide stable results even over several meters. Glossy and reflective surfaces are reliably detected as well.

Requirement:

Encoded information on the SKID must be detected contact-free in order to track the production process. Sufficient distance between the sensor and SKID/AGV must be ensured to avoid impeding the path of the AGV.

Solution:

Bar code and RFID technology are suitable for reading encoded information. Bar code technology directs the read data to a central database. Decentral automation does, however, also require the writing of data. RFID technology is used here: the RFM 32 RFID read/write systems or, for larger operating ranges, the RFM 62.

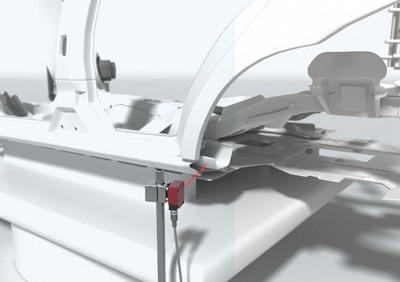

Requirement:

The presence of components as well as shapes, holes and openings or other special features is to be detected prior to joining and processing. The detection must often be performed from a safe distance.

Solution:

The HT 3 diffuse reflection sensors with background suppression for shorter operating ranges and HT 46C for longer operating ranges ensure reliable presence control. Models with various light-spot geometries offer optimum adaptation to the application. Flexible mounting brackets, cables and IO-Link models are available.

Requirement:

A type test is necessary for the respective work step. This is performed by detecting structural elements in various models. Because the tests are to take place during the running work process, the sensors must be installed outside of the robot work areas.

Solution:

The compact ODS 110 / HT 110 measuring and switching TOF sensors are suitable for restricted installation locations. They offer an operating range of up to 5 m. For larger operating ranges, the ODS 10 / HT 10 devices are used.

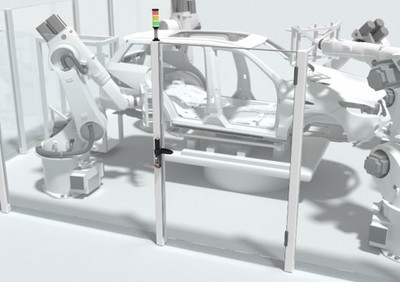

Requirement:

Areas with hazardous movements can be entered via safety doors to allow maintenance. If the movement does not stop immediately after the door is opened, the door is to be guarded by a safety switch with locking device. Work and safety conditions are to be signaled.

Solution:

The robust safety switches with locking device of the L series lock safety doors until they are released by means of an electrical signal. In addition to the standard models, there are devices with integrated control buttons and emergency stop as well as devices with RFID-coded actuator. Optical and acoustic signalers of the A7 series complement the integrated LED status displays.

Requirement:

The danger zone of the robot and the working range of the transfer station should be safeguarded against entry by persons during the entire process. The vehicle should be able to enter and exit the work area fully automatically.

Solution:

The safety solution for robots / AGV transfer stations secures the entire area around the transfer station through safety laser scanners. As the vehicle passes through, the protective field dynamically adapts to the position of the vehicle by blanking the outline of the AGV from the protective field.

Requirement:

For quality and completeness monitoring, shapes or features are to be detected and, depending on the task, checked for tolerance, accuracy, dimensional accuracy as well as completeness. The transfer of coordinates and parameters is to be performed either via digital inputs/outputs or via serial interfaces.

Solution:

In addition to BLOB analysis and code reading, the LSIS 462i smart camera can also be used to measure distances and geometric shapes (circles, lines and edges) under a single user interface. Eight freely programmable inputs/outputs and an industrial Ethernet interface are available for communication.

Requirement:

Before the AGV can begin travel to the next workplace, the presence and correct positioning of the body on the AGV must be checked. This is to be performed by detecting a prominent body part at a precisely defined distance.

Solution:

The economical, diffuse reflection sensors with background suppression of the HT 25C series impress even with glossy materials thanks to their high detection reliability. Models with red light, infrared and laser of protection class 1 as well as various light spot sizes enable optimum adaptation to the requirements.

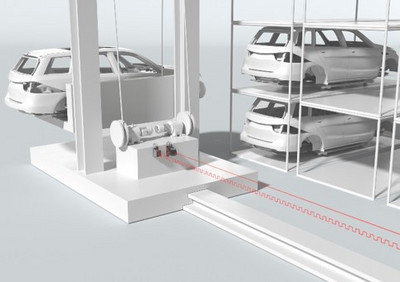

Requirement:

The stacker crane or lifter must be positioned in the x-direction (travel axis) and y-direction (lifting axis) appropriately for the pallet that is to be moved to. Travel commands and positioning data are to be optically transferred to the control to ensure high availability of the system.

Solution:

The AMS 300i laser distance measurement devices or BPS 300i bar code positioning systems are used for the exact positioning. The DDLS 500i data transmission photoelectric sensors function fault-free without offset directly next to the AMS 300i devices. Selectable operating ranges, interfaces and protocols ensure optimum solutions.

Requirement:

To check whether the lifter exit is clear, the presence of the SKID or body on the lifter is to be checked.

Solution:

Inductive switches are suitable here. Because SKID and lifter tolerances are to be compensated for, sensors with a large scanning distance are recommended, e.g., IS / ISS 244 cubic designs or cylindrical designs with triple switching distance from the IS 200 series.

Requirement:

Before a body can be moved from the lifter to a free compartment, a check must be performed to determine whether the compartment is free or occupied. To be able to store different bodies, the SKID is to be used for detection.

Solution:

The HRT 25 LR compact diffuse sensors are used for operating ranges up to 2.5 m. If larger operating ranges are required, the ODS 10 measuring distance sensors or HT 10 switching diffuse sensors are suitable.