More than you expect.

Packaging. Sensors. Solutions.

The demands on manufacturers of packaging machines and consumer goods are high and dynamic: consumers expect innovative and sustainable packaging materials, brand and consumer protection are gaining in importance and e-commerce is the defining trend in retail. Packaging processes in the food and pharmaceutical industries must become increasingly flexible, efficient and intelligent.

Our broad product range includes sensors for the entire packaging process – each tailored to your specific requirements. While hygiene requirements are very high in sausage and cheese processing or in the pharmaceutical industry, speed and efficiency are additionally important in the beverage industry. In confectionery packaging, the focus is on flexibility and easy format changes. Together with our customers, we have been developing the right solution for every application for over 60 years. No matter whether this involves individual standard sensors, special sensors or complete solutions. Our goal is to ensure that your systems are available and your production processes are reliable, safe and trackable.

Our highlights for packaging processes in the food and pharmaceutical industry

Simple Vision sensors: IVS 108 and IVS 1048i / DCR 1048i

As easy to use as an optical sensor with high performance comparable to a camera system – the unique Simple Vision concept from Leuze. The new product range offers quick and easy entry into image processing used in industrial automation.

New range of sensors for hygiene-sensitive production processes

Our new stainless steel sensor platform with the 53C series in hygienic design and 55C in wash-down design was especially developed for applications with increased hygiene requirements.

High-speed retro-reflective photoelectric sensors for highly transparent objects

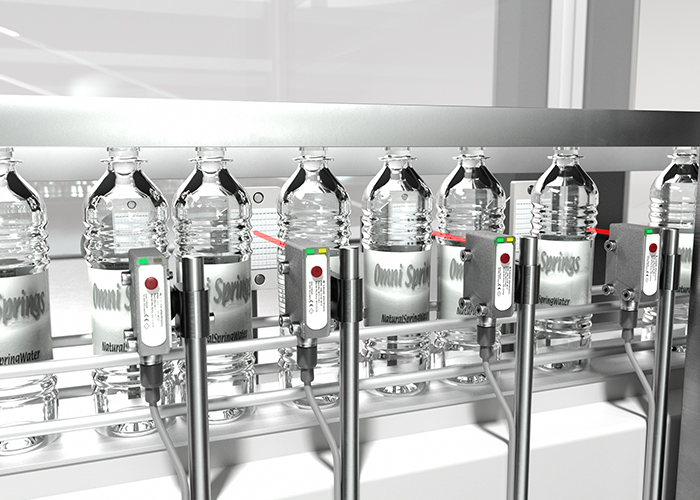

The sensors of the PRK 18B series detect preforms and PET or glass bottles extremely quickly and reliably. A special tracking function compensates for contamination and increases the cleaning intervals.

Most powerful throughbeam photoelectric sensors for detection through film

The LS25CI photoelectric sensors have been developed to solve the problem of detecting objects through film. They are so powerful that they even detect objects through metalized packaging film.

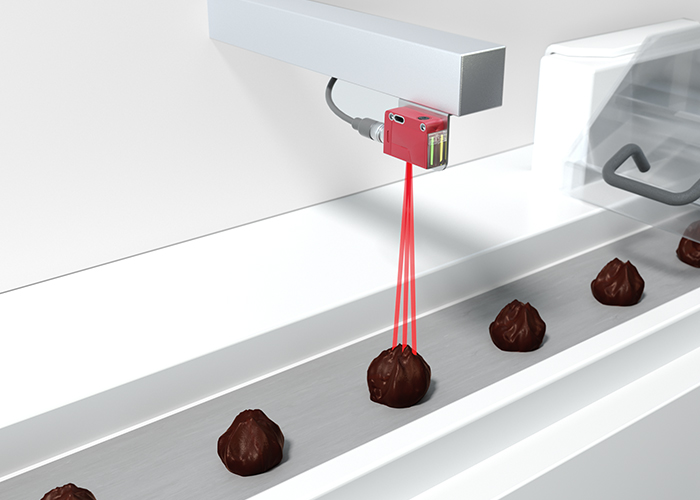

Dynamic reference diffuse sensors for object-independent detection

The DRT 25C dynamic reference diffuse sensor is equipped with intelligent "Contrast Adaptive Teach" (CAT) technology and specializes in detecting challenging shapes or surfaces – without adjustments having to be made at the sensor in the case of format changes.

Flexible and precise: Ultrasonic sensors with adjustable sound cone

New cubic ultrasonic sensors with small dead zone and three adjustable sound cone widths for precise switching and measurement results.

Your task – our solutions

The processing and packaging of food and pharmaceuticals is subject to stringent requirements. We support manufacturers of packaging machines and producers of consumer goods by providing sensors and application advice.

Detection of transparent objects

The detection of transparent objects often poses a challenge for sensor systems. We offer sensors specially designed to detect preforms, bottles and films.

Detection through film

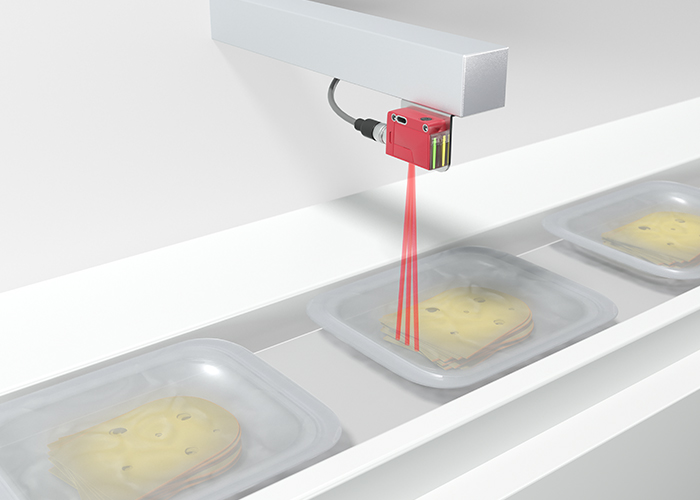

To seal the film and to separate the products, their position inside the film first needs to be detected. The most powerful throughbeam photoelectric sensors detect packaging contents through the film.

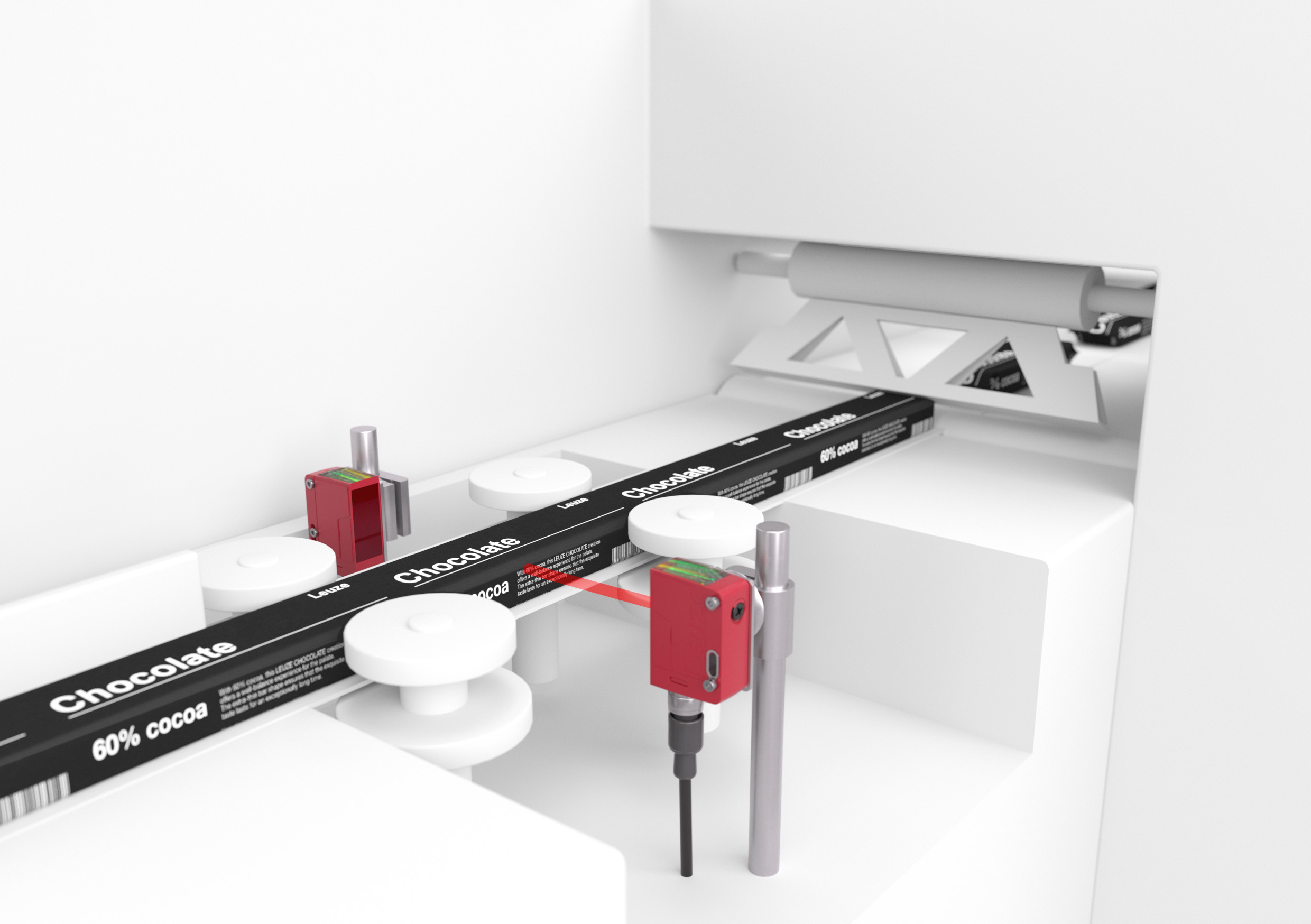

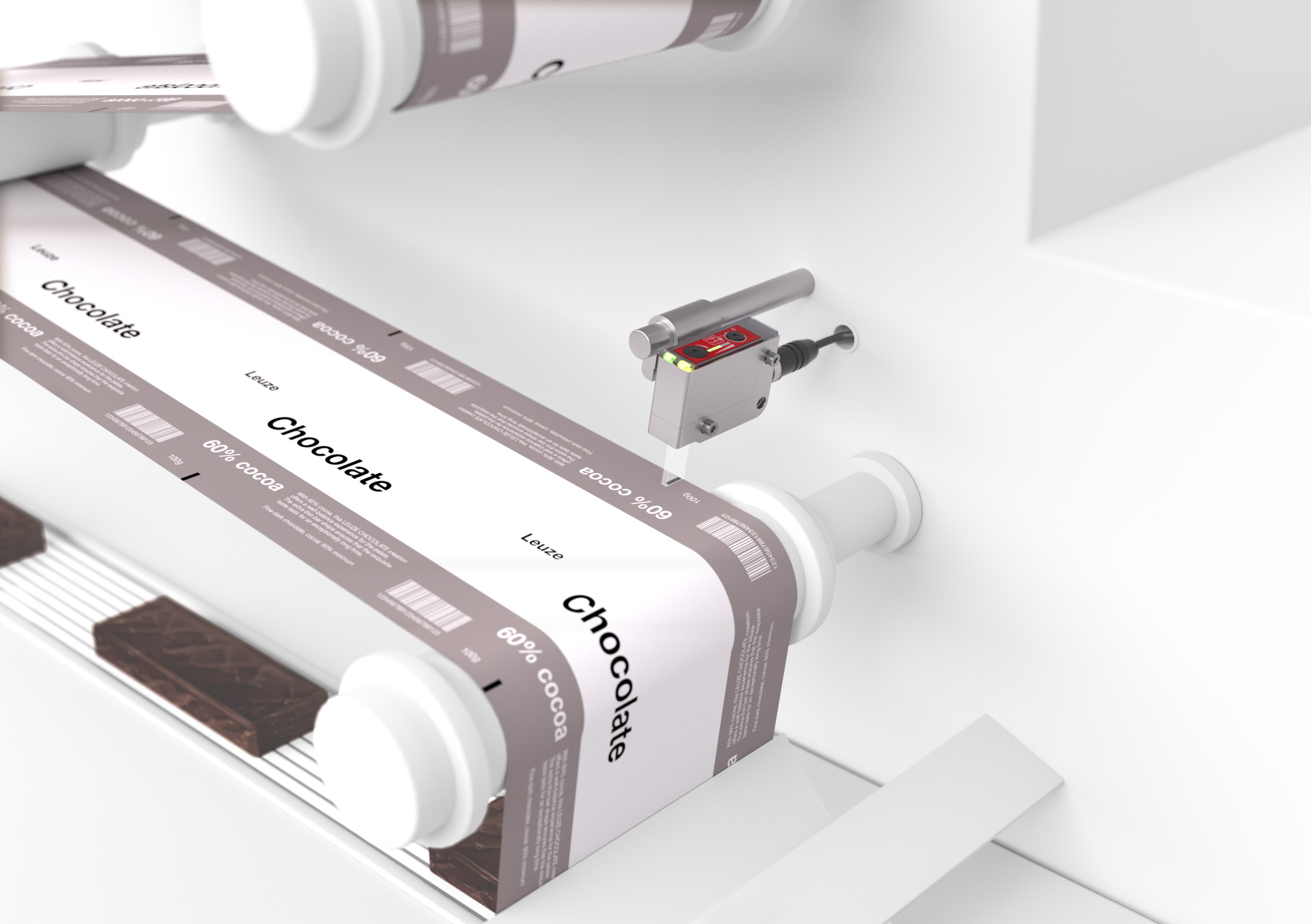

Contrast and cut mark detection

Contrast sensors are developed to detect defined markings on objects during packaging processes. These contrast markers are located on film, bag and blister packaging or on labels.

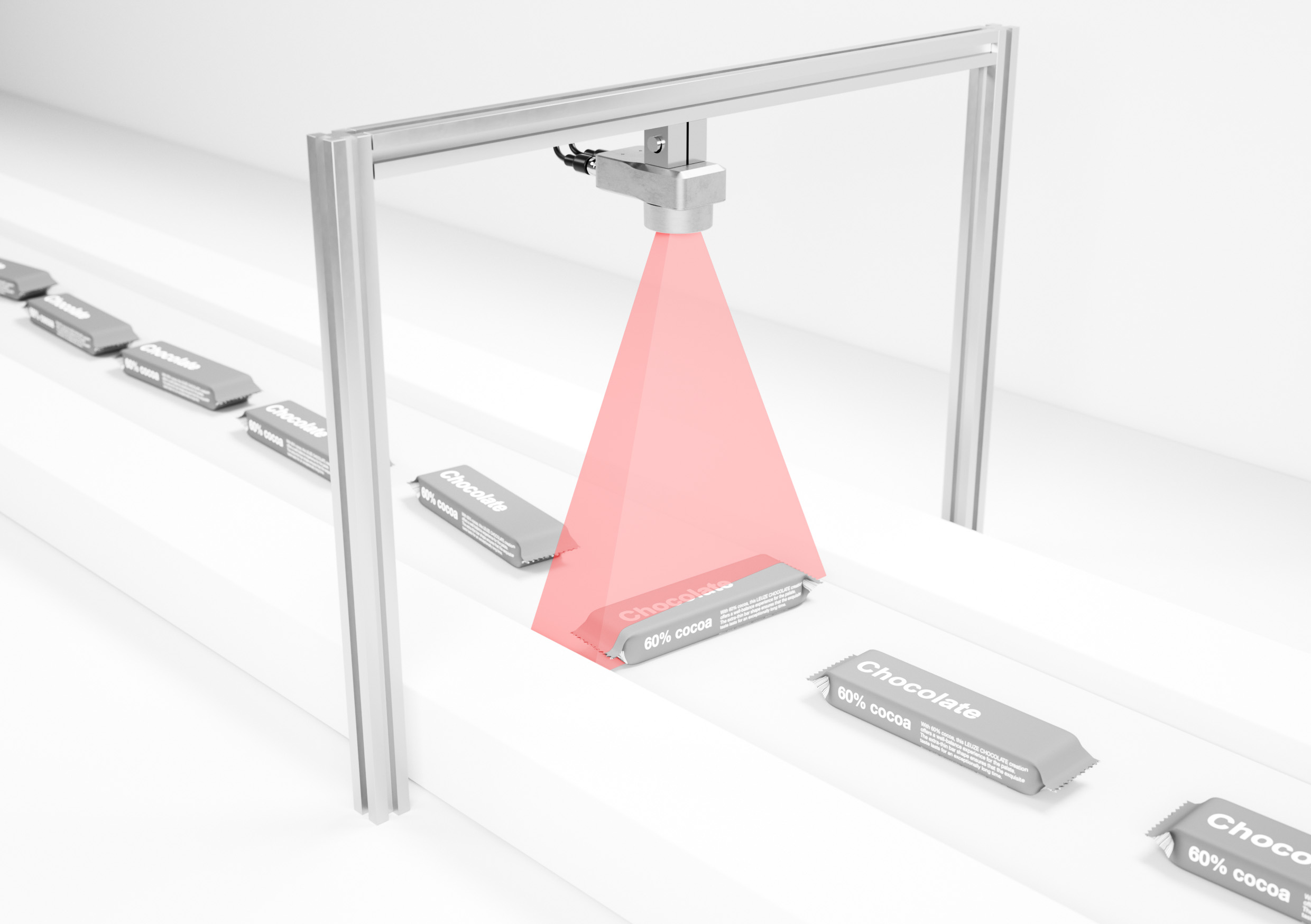

Object-independent detection (DRT)

Sensors must detect a wide variety of products and films on the conveyor belts of packaging machines. Our dynamic reference diffuse sensors detect objects with challenging shapes and surfaces – with the conveyor belt serving as the reference.

Filling level measurement

Reliably detecting the fill level of aqueous liquids in all types of containers is one of the most challenging detection tasks for sensor systems and requires extremely powerful sensor solutions.

Labeling

Labels in various shapes and sizes as well as different materials and textures are affixed to products and packaging by means of labeling machines. Fork sensors detect labels reliably and ensure the high quality of label attachment.

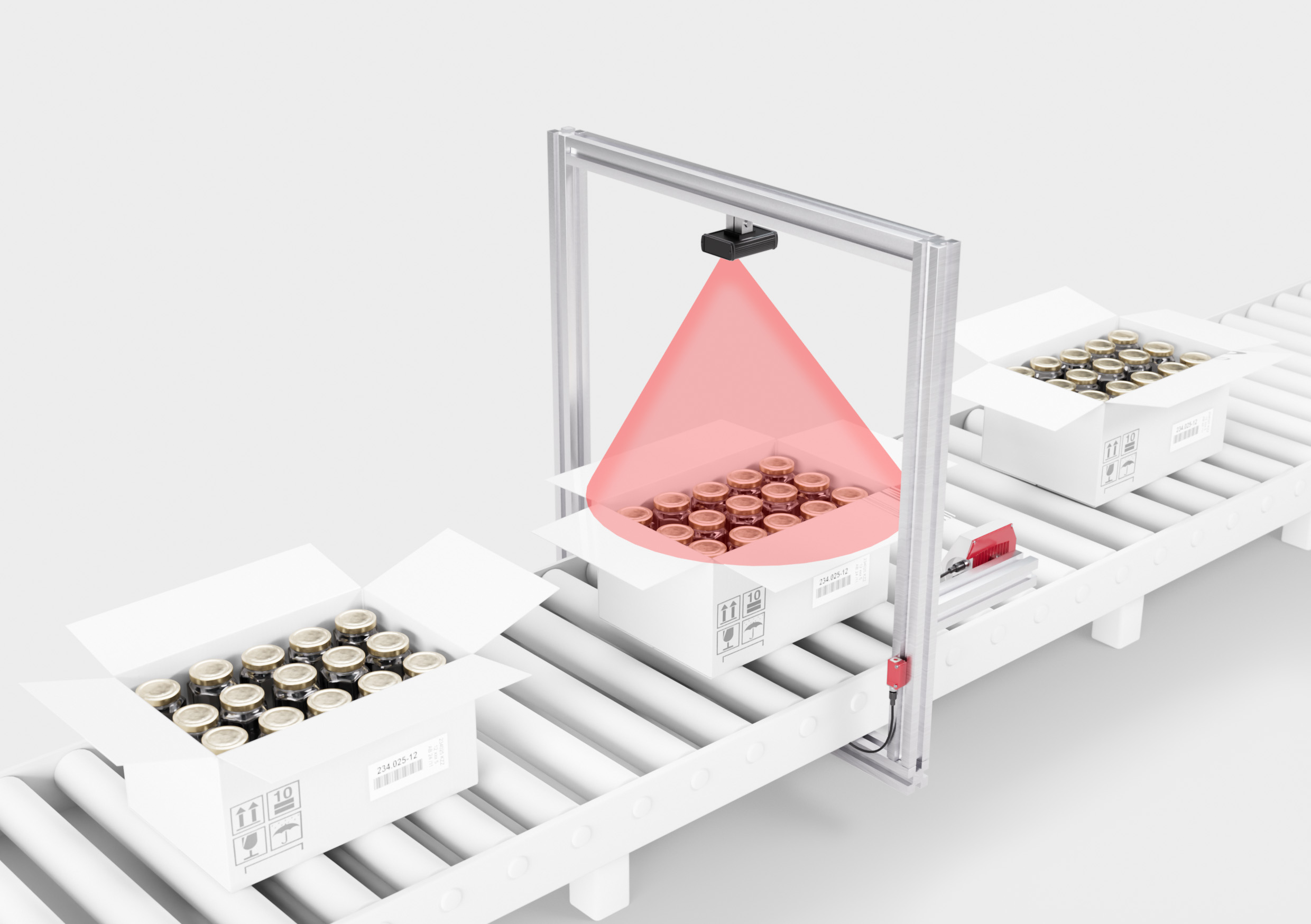

Detection, inspection and identification

Whether presence or absence detection, part detection or inspection, measuring or counting – The Simple Vision product range offers simple introduction to image processing.

Camera-based 1D/2D scanners read codes even while in motion and have a wide area of application.

Visual monitoring

Solutions for industrial image processing enable machines to "see" so that manual inspection tasks can be replaced or supplemented by the use of digital cameras and functions for digital image processing.

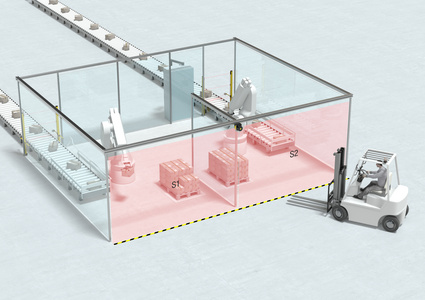

Machine safeguarding

With a comprehensive portfolio to satisfy all safety requirements, we offer you complete safety, an efficient flow of materials, and maximum availability levels worldwide.

Areas of application

Interview: Increasing efficiency in the packaging industry

Our packaging expert is here for you: Andreas Eberle

Ph.: 07021 / 573 177

E-mail: Andreas.Eberle@leuze.com