Ultrasonic sensors

Advantages for you

- Reliable detection of liquids and solid objects with sound-reflecting surfaces

- Can also be used under harsh ambient conditions: ultrasonic sensors are not affected by steam, humidity, dust or ambient light

- Maximum flexibility for your application: with 4 different sizes (M8, M12, M18, M30) and operating ranges between 0.1 m and 6 m

- Flexible use thanks to switching and measuring models in one series

- Object detection and presence control with switching ultrasonic sensors (HTU)

- Distance measurement with ultrasonic distance sensors with analog output (DMU)

- Short length allows use even in confined spaces

- Robust metal housing

- The sensors are dust-proof and achieve degree of protection IP 67

- Quick and easy operation of the sensors with IO-Link interface

Highlights

Detection of glossy, reflective, transparent or dark objects

Ultrasonic technology is able to capture objects regardless of their surface properties. The new ultrasonic sensors detect solids, liquids, powders or granulates extremely reliably.

Specialist for constrained spaces and small container openings

The HTU208 compact ultrasonic sensors in M8 size have been developed for use in small installation spaces. The switching sensors feature an extremely narrow sound cone and detect fill levels even in the case of containers with small openings.

Simple connection to an automation system via IO-Link

The new ultrasonic sensors of the HTU200 and DMU200 series are set up either remotely by teaching via cable or – for maximum convenience – via IO-Link. Using IO-Link, sensors can easily be integrated in an automation system. This type of automation simplifies integration and thereby helps keep downtime in production to an absolute minimum. The new compact and robust ultrasonic sensors can be configured, operated and maintained (condition monitoring) via IO-Link.

- Keeping an eye on processes: using the internal object counter and diagnostic data such as temperature (predictive maintenance)

- Real-time signal information and diagnosis

- Precise measurement value output even in the case of devices with digital switching output

Application

Fill level monitoring of bulk material

Requirement:

When granular bulk materials are filled, fill levels are to be detected reliably. Dusty ambient conditions occurring when granulates or powders are filled must not affect detection.

Solution:

The new ultrasonic sensors of the 218 series, available with staggered operating ranges, are well suited for fill level monitoring in dusty environments. The large detection range of the ultrasonic cone makes reliable fill level monitoring possible, even in the case of granular objects. A HTU218 switching ultrasonic sensor detects the upper limit of the filling. Alternatively, a measuring distance sensor can be used. It is designed for continuous fill level monitoring based on the output of an analog value (using current or voltage).

Fill level monitoring in the case of containers with a small opening

Requirement:

On a filling line, the fill level is to be detected through a very narrow container opening.

Solution:

The new HTU208 compact ultrasonic sensor in the form of an M8 threaded sleeve has an extremely narrow sound cone and thereby enables fill level monitoring through very small container openings.

Stack height monitoring using an ultrasonic distance sensor

Requirement:

In a cartoning machine, the fill level of the folding box magazine is to be detected. The carton can have different colors, surface structures and perforations. Therefore, detection is as far as possible to be performed irrespective of the material and surface.

Solution:

Thanks to detection using the ultrasonic cone, the ultrasonic sensors of the DMU200 series are ideal for distance measurement irrespective of the material and surface of the carton. The wide sound cone means that punched-out holes in the carton are also no problem.

Loop control in the automotive industry

Requirement:

In a cutting system used in the automotive industry, the cutting process must be decoupled from the belt transport. The sag of the loop is to be determined contact-free to communicate the necessary measurement values to the control for determining the haul-off speed.

Solution:

The measuring ultrasonic sensors of the DMU218 or DMU230 series with various operating ranges and robust metal housing are suitable for loop control. They are available with analog current or voltage output and IO-Link interface.

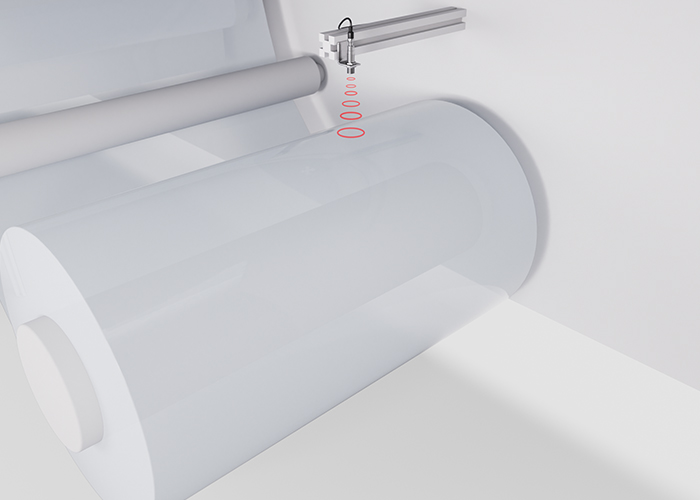

Monitoring the diameter of rolled products

Requirement:

Packaging material, labels or films in different colors and materials are provided on rolls. To ensure uniform unrolling of the rolled product, the axis is motor-driven. The roll diameter must be monitored continuously to ensure the availability and prompt changeover of the rolled product.

Solution:

The new distance-measuring ultrasonic sensors of the DMU218 series send an analog output signal, which is proportional to the roll diameter, to the control. This makes it possible to determine in good time when the roll needs to be changed.

Many models to ensure high flexibility for your application

The new range of sensors includes switching and measuring ultrasonic sensors in different sizes, with various operating ranges and switching outputs. Some models have an IO-Link interface and allow extremely quick and easy operation.

Switching ultrasonic sensors:

- HTU 208 (4 models)

- HTU 212 (8 models)

- HTU 218 (6 models)

- HTU 230 (2 models)

Measuring ultrasonic sensors:

- DMU 218 (4 models)

- DMU 230 (4 models)

Technical properties

| Feature | HTU 208 | HTU 212 | HTU 218 | HTU 230 |

| Housing material | Brass (nickel-plated) | Brass (nickel-plated) | Brass (nickel-plated) | Brass (nickel-plated) |

| Operating range | 20 - 100 mm | 20 - 200 mm | 80 - 800 mm | 300 - 3000 mm |

| Switching frequency | 20 Hz | 20 Hz | 5 Hz | 3 Hz |

| Response time | 25 ms | 25 ms | 100 ms | 166 ms 250 ms |

| Ambient temperature, operation | 0 - 50°C | -25 - 70°C | -25 - 70°C | -25 - 70°C |

| IO-Link | - | - | V1.1 (COM2) | V1.1 (COM2) |

| Operation | Teach via cable | Teach via cable | Teach via cable |

|

| Switching output | PNP, NPN | PNP, NPN | PNP | Push-pull (IO-Link) |

| Analog output | - | - | Current (4 … 20mA) | Current (4 … 20mA) |

| Degree of protection | IP67 | IP67 | IP67 | IP67 |

| Certification | CE, UL, UKCA, China RoHS | CE, UL, UKCA, China RoHS | CE, UL, UKCA, China RoHS | CE, UL, UKCA, China RoHS |

| Connection | M8 (4-pin) | M12 (4-pin) | M12 (4-pin) | M12 (4-pin) |