Prepared for the car of the future

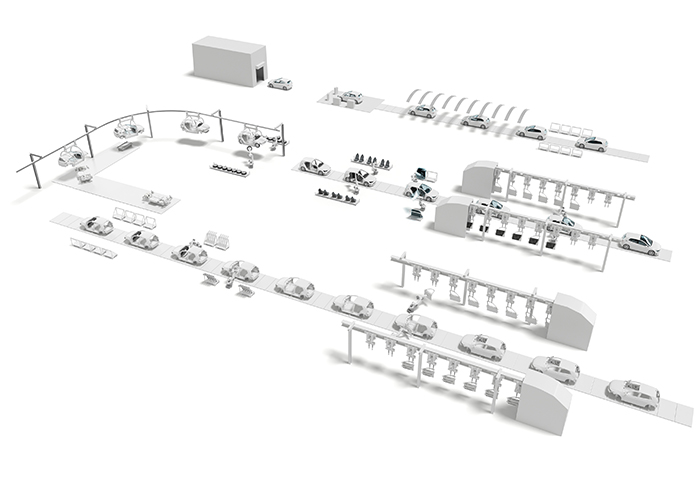

The market for alternative drives is growing rapidly. An increasing number of models and equipment options require even more flexible production and an extensive quality management system. Our goal, as a partner for our customers, is to ensure your success in an industry that is ever evolving. The automotive industry in particular currently faces great challenges.

Based on years of industry knowledge, we orient our product range toward current and future application solutions. Predictive maintenance and diagnostic possibilities for Industry 4.0 are as much in focus as high system availability and smooth production processes.

Flexible manufacturing and e-mobility

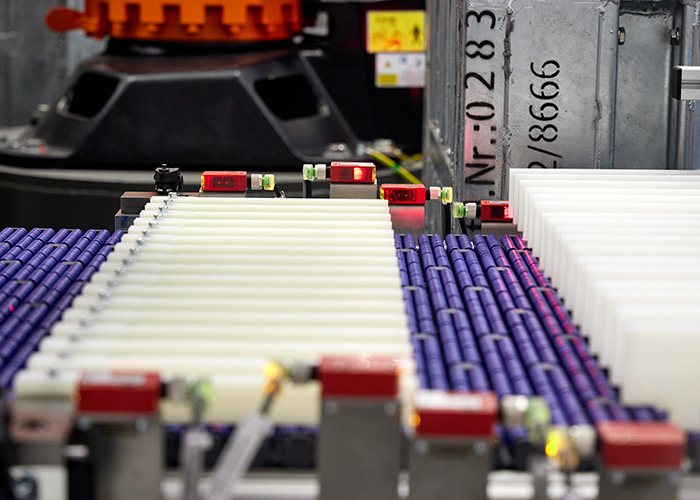

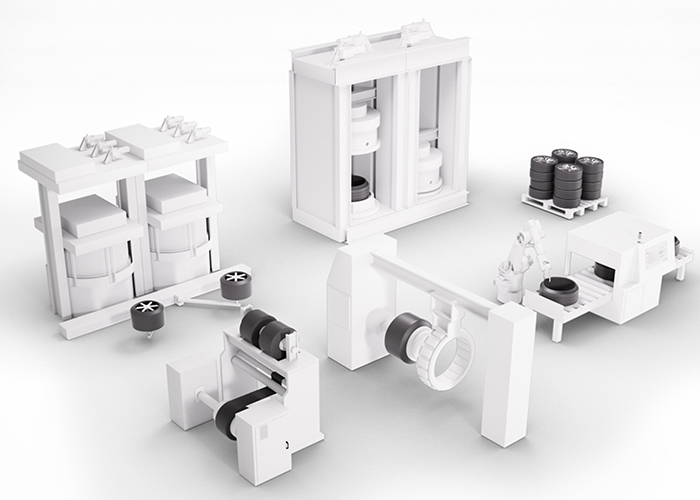

The production processes in the press shop, paint shop and final assembly are becoming increasingly flexible. Different vehicle models and equipment options need to be taken into account in the process. Scalable manufacturing concepts that can be adapted to production capacities are called for here. The trend towards emission-free vehicles is also changing manufacturing processes. The complexity and the number of components in the powertrain is decreasing, and the production of batteries and battery packs is growing.

Maximum system availability and certified quality standards

Our sensors support you in all areas of automation, quality assurance, traceability and machine safety. They stand out for their easy handling during commissioning and replacement. With sophisticated functions, intelligent devices ensure smooth production and material provision. The long-term quality as well as the availability of the sensors are guaranteed. Our products thereby help to ensure and maintain the high availability of the system.

Safety without compromise

The advance of automation gives rise to new requirements with regard to the safety of persons and machines. Through our specific application know-how and more than 30 years of experience in the area of machine safety, we offer unique insight into safety-related applications. With our safety product range consisting of high-quality products, intelligent systems as well as competent technical services, we provide you with targeted answers.

Application report: Precise processes for the e-drive