The press shop

From the steel coil to the car.

Various body parts for the subsequent finished vehicles are produced from massive steel rolls, so-called coils.

Whether for cutting the coils or punching, pressing and shaping the blanks: sensors accompany and safeguard all manufacturing steps, even under harsh environmental conditions.

The applications are as diverse as our product range, which is tailored to these applications. Inductive and optical sensors check and monitor the presence and position of parts. Identification systems record data for the traceability of those parts. At the cutting systems, our sensors supply measurement values for loop control and edge control.

Requirement:

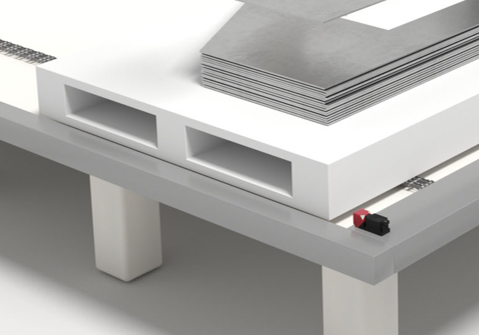

The cut, in some cases, already stamped blanks are fed for further processing by means of forklift trucks or automated guided vehicles. Before the parts can be accepted, a check must be performed to ensure that the pallet or load carrier has reached the transfer position. This is to occur contactlessly.

Solution:

The inductive switches of the IS 200 / 244 series offer high performance and large function reserve. Depending on the installation location and the required operating range, both cylindrical designs with triple switching distance from the IS 200 series as well as the IS / ISS 244 cubic versions are available.