Simple Vision sensor for presence detection

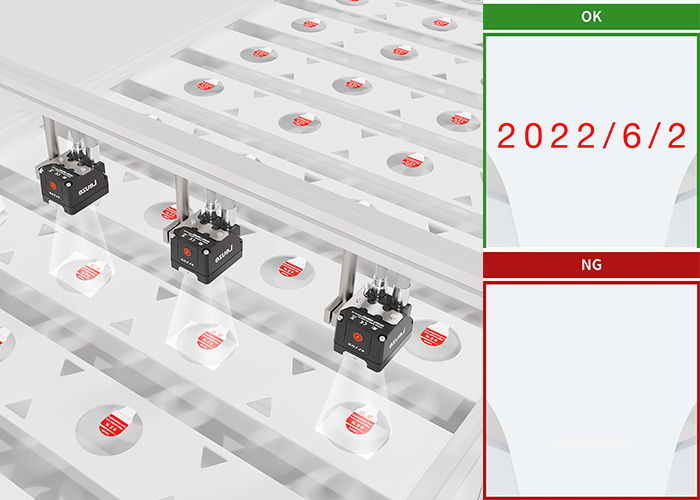

With the new IVS 108 Simple Vision sensor, detection tasks encountered in packaging processes can be solved using an easy-to-operate, image-processing sensor.

Overview

The new IVS 108 Simple Vision sensor

Extremely easy to use – perfect for presence detection

The new IVS 108 is an innovative Vision sensor that can detect the presence or absence of objects in a simple way. It offers outstanding performance for a wide variety of detection tasks. The IVS 108 is intuitive, can be adjusted quickly and is as easy to use as an optical sensor.

Technical properties

| Feature | IVS 108 |

| Electrical data | |

| Power supply | 10 … 30 VDC |

| Power consumption | 4.2 W |

| Integrated illumination | 4 high power, white, polarized |

| Alignment aid | 2 x LED, red |

| Interfaces and protocols | Digital I/O, Ethernet 100 Mbit/s with TCP/IP |

| Digital switching inputs | 2x optical coupler (teach and trigger) |

| Digital switching outputs | 3x PNP/NPN/push-pull (selectable for GOOD, NO GOOD and data valid) |

| Response time | 50ms fixed |

| Optical data | |

| Camera type | Monochromatic black/white |

| Working distance WD | 50 ... 150 mm |

| Field of vision FoV | WD=50 mm: 22 mm x 16 mm; WD=150 mm: 55 mm x 41 mm |

| Opening angle, horizontal | 19º |

| Opening angle, vertical | 14.5º |

| Focus adjustment | Motorized adjustment of focal position with autofocus |

| Camera shutter | Global shutter |

| Mechanical data | |

| Dimensions (H x W x D) | 58 x 47 x 38 mm (without connections) |

| Fastening | 2x M3 thread, spacing 37.6 mm |

| Adjustment and indicators | |

| Teach button | Teach GOOD / NO GOOD (alternatively via webConfig) |

| Indicators on top of sensor | HMI with 5 LEDs |

| On rear of sensor | Status LED for voltage (blue) and Ethernet connection (yellow) |

| On front of sensor | LED GOOD: green; LED red: NO GOOD |

| GUI (optional alternative to teach button) | webConfig via Ethernet |

| Other | |

| Image memory | 6 internal |

| Number of jobs | 32 (job 0-31) |