Sensor solutions for tire production

Tire production places special requirements on the automation and sensor systems used. These mainly result from the optical and physical properties of the objects being detected – typically matte black materials – as well as from process-related factors such as heavy contamination, varying surface textures, and demanding environmental conditions.

Areas of application

Tires for motor vehicles are manufactured in specialized rubber processing plants and then delivered to the car manufacturers for final assembly. Tire production places high demands on the sensor systems used there: The raw material used is predominantly jet black and light-absorbent, while the production environment is often characterized by high levels of contamination and tough environmental conditions. Our sensors are specifically designed for these challenges. They provide reliable process monitoring while also enhancing occupational safety in automated system environments.

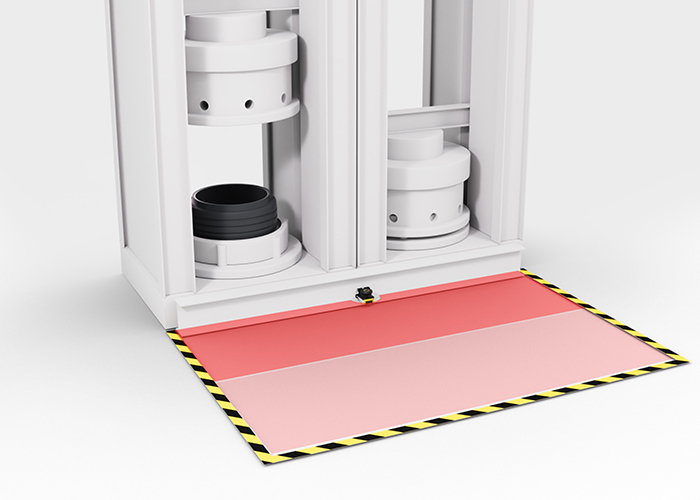

Tire detection on vulcanizing machine

Requirement:

Reliable object detection of the tires is required to precisely control the individual process steps on the machine – even with extremely low reflection due to the typically deep black surface. In addition, the system must reliably distinguish between different tire sizes.

Solution:

The ODT 25C series optical distance sensors with time-of-flight (ToF) technology and infrared light enable reliable object detection with high angle tolerance. Measurements from two independently adjustable distances allow different tire sizes to be reliably detected. Measurement distances can be conveniently configured and additional diagnostic data efficiently evaluated via the IO-Link interface.

Area safeguarding in harsh environmental conditions

Requirement:

A flexibly adaptable area safeguarding system is required upstream of the vulcanizing machine, which enables rapid switching between different protection configurations.

Solution:

The RSL 200 safety laser scanner is easy to integrate into the machine due to its compact design. Its wide detection angle and up to 32 configurable protective fields that can be created via USB, Bluetooth or Ethernet mean it provides maximum flexibility. For efficient maintenance and quick diagnosis – especially in hard-to-reach installation positions – the RSL200 app conveniently supports all service and inspection tasks.

Code reading for wheel allocation

Requirement:

The complete wheels – consisting of tires and rims – are transported to the assembly line on an order-by-order basis. To ensure that the wheels are correctly assigned to their respective vehicles, the barcode on the label must be reliably read. The label may be located anywhere on the tire circumference.

Solution:

Several BCL 500i or BCL 600i series bar code readers are used to cover the tire’s entire circumference. These devices offer a wide reading range and depth of field, so bar codes are reliably captured regardless of their position. The code reconstruction technology allows individual partial readings to be combined into a complete result, ensuring fast and reliable identification.

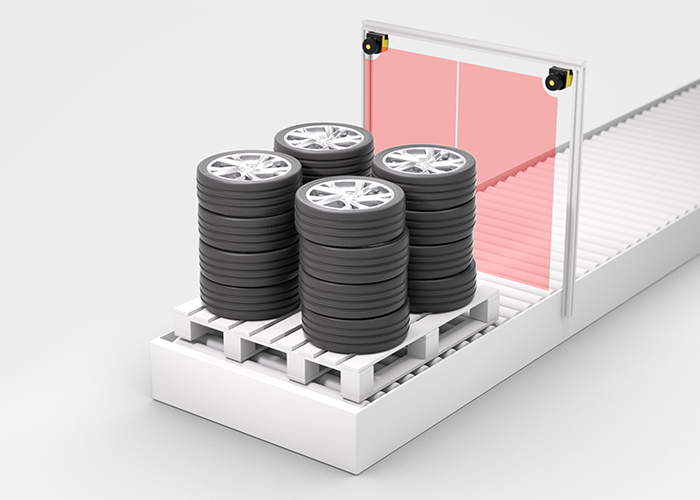

Stack alignment

Requirement:

The tire stacks’ alignment must be reliably checked before they are automatically depalletized. At the same time, access to the depalletizer must be guarded to ensure the safety of the operating personnel.

Solution:

The RSL 400 safety laser scanner combines both tasks in one device: Thanks to its high angular resolution and ability to output measurement data, the stack alignment can be checked while still protecting access. The protective fields’ flexible design as well as the staggered operating ranges enable application-specific optimization and ensure maximum safety and efficiency during operation.

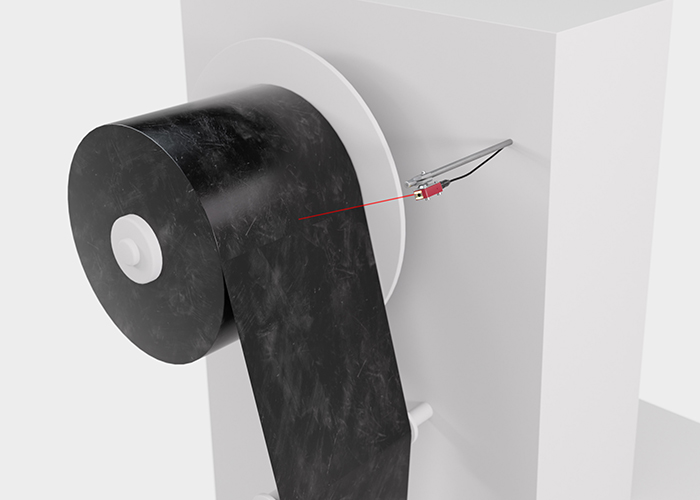

Measurement of the remaining rubber band

Requirement:

A continuous distance measurement relative to the axis is required for precise control of the rubber band’s unwinding process.

Solution:

The compact ODT 3C distance sensors are easy to integrate into the system and provide highly accurate distance values via IO-Link. This provides reliable process control and optimal regulation of the unwinding process.

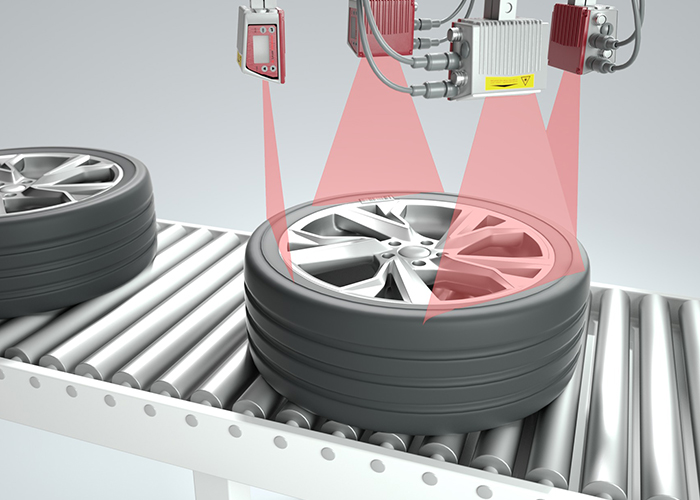

Tire identification on the hot press

Requirement:

For the subsequent process, the tires must be reliably identified on the hot press – both in rotation and for different diameters within a defined measurement range. Varying code quality requires special evaluation functions.

Solution:

The BCL 500i code readers reliably capture large reading fields with their oscillating mirror and code reconstruction technology. The integrated interfaces as well as the WebConfig function allow easy integration into the machine control system and efficient configuration.

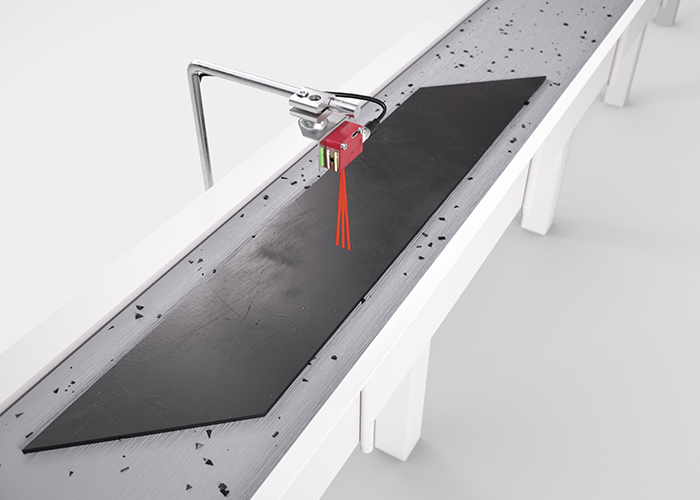

Detection of rubber parts

Requirement:

Black rubber is difficult to detect optically due to its low reflectivity. In addition, heavy contamination of the conveyors during the production process makes detection more difficult.

Solution:

The DRT 25C and DRT 35C reference diffuse sensors use the conveying belt as a reference, which allows even extremely dark objects to be reliably detected – even in heavily contaminated environmental conditions. The teach function with 2 or 3 adjustable sensitivity levels enables quick and convenient adaptation to different process conditions.