Robotics

As demand grows for flexible material flow in production, warehousing, and order picking, new transport routes are increasingly implemented with automated guided vehicles (AGVs) rather than roller or belt conveyors, allowing process changes to be introduced more quickly.

At the same time, process steps with robotic support, such as the assembly of individual parts, are increasing. This field is known as robotics and requires the use of special sensors for automated tasks. A basic distinction is made between mobile and stationary applications.

Our broad portfolio enables us to implement suitable solutions.

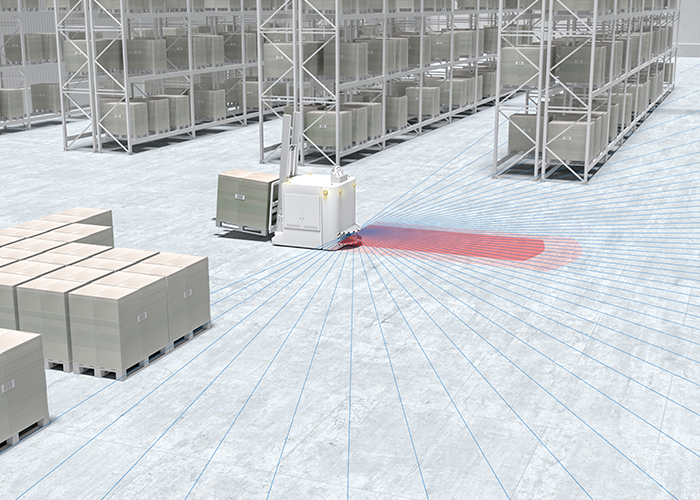

Safeguarding the transportation path and navigation

Requirement:

If the principle of natural navigation is used, the safety sensor should simultaneously provide the measurement data for the navigation software in addition to safeguarding the transportation path in different driving situations.

Solution:

The RSL 200 / RSL 400 safety laser scanner merges safety technology and high-quality measurement value output in a single device. It has up to 100 switchable field pairs. The measurement data have a high angular resolution of 0.1°, which allows a very accurate map of the environment to be created.

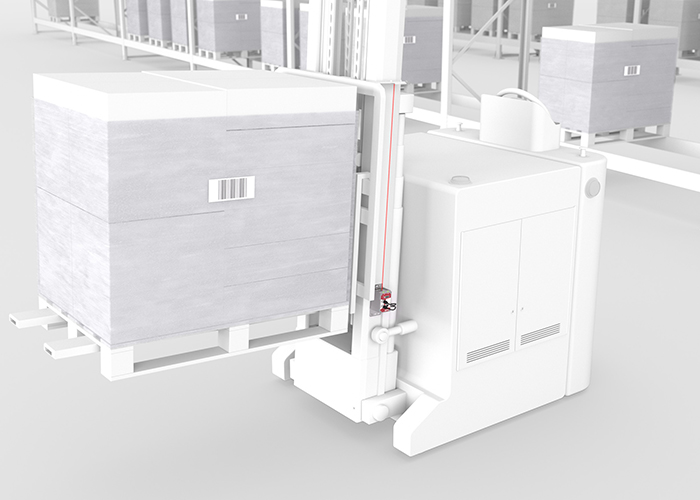

Vertical positioning of the load receptacle

Requirement:

For reliable storage and retrieval of the pallet, the load receptacle must be positioned precisely and repeatably at the correct height.

Solution:

The AMS 100 laser positioning system delivers measurement data every 2 ms with an absolute accuracy of ± 2 mm. The data can be transferred to the control via a wide range of interfaces.

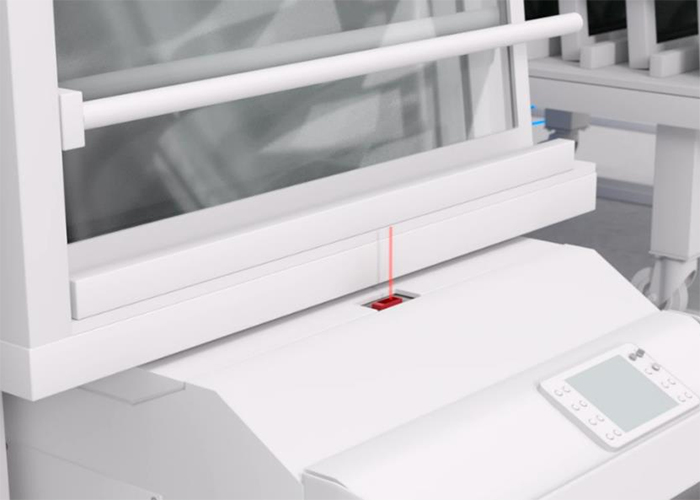

Presence / position control of the pallet

Requirement:

After transferring the container/pallet to the shuttle, check whether the load carrier has been placed correctly. To this purpose, the presence of the ‘load’ is to be checked at one or more defined positions on the shuttle.

Solution:

The HT 3C optical sensors reliably detect load carriers thanks to active background suppression and ambient light sensitivity. The HT 3C series offers robust solutions, e.g. for the detection of objects with colored structure, objects with openings or highly polished surfaces.

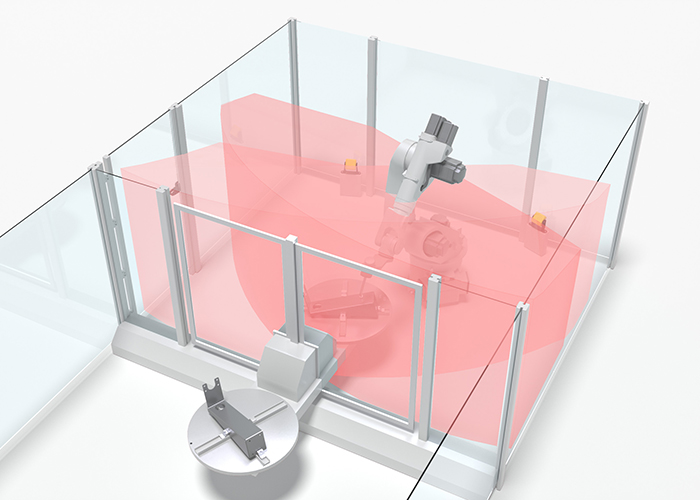

Restart protection and monitoring of hidden areas

Requirement:

To prevent danger, the process is not permitted to restart until it has been ensured that no persons are in the working range or in the hidden area. Safe operation and high availability must also be guaranteed under harsh ambient conditions – such as dirt or welding sparks.

Solution:

With its protected area, the LBK 3D safety radar system monitors for the presence of persons – even under harsh ambient conditions. Furthermore, the radar technology allows the presence of static objects in the monitored area.

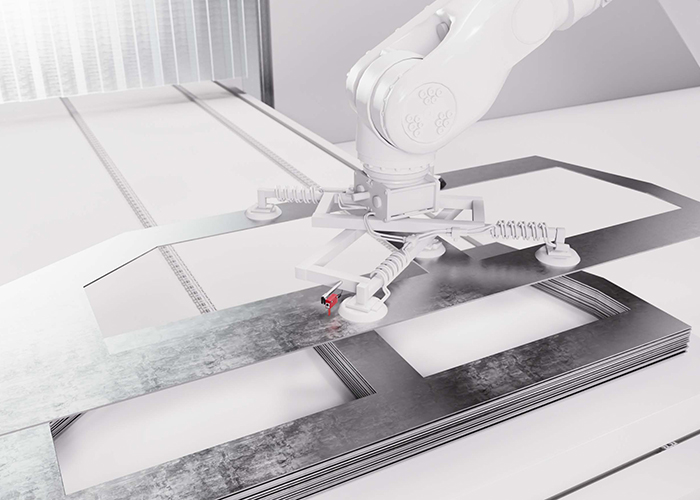

Presence check of the material on the gripper

Requirement:

A suitable sensor must be used directly on the gripper to detect when the gripper is correctly positioned on the material. A distance value is useful for an optimized approach.

Solution:

The very compact ODT 3C optical distance sensors with a large working range of up to 2.5 m and value output via IO-Link are easy to integrate and significantly increase process safety.