Laser scanners

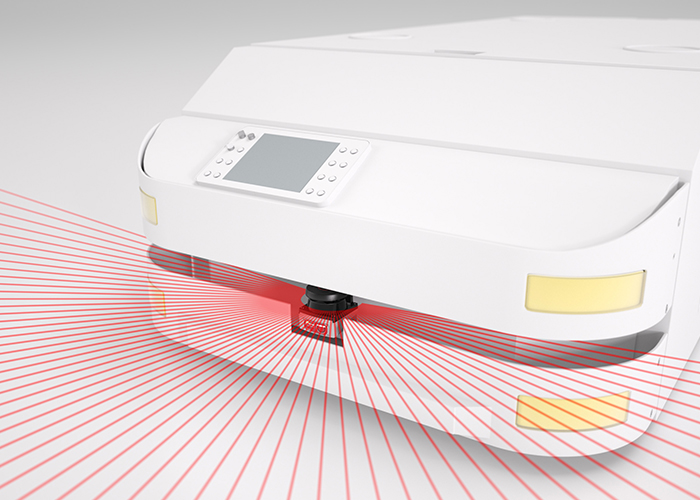

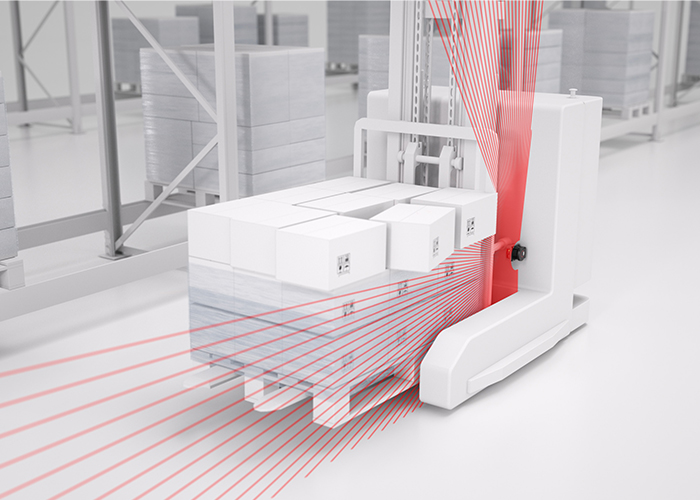

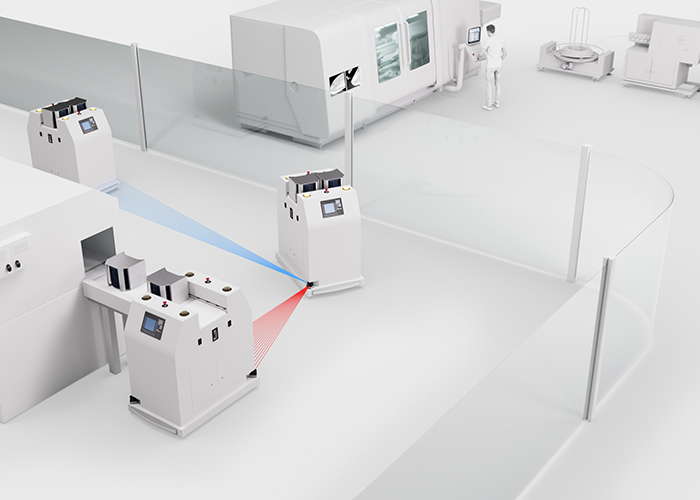

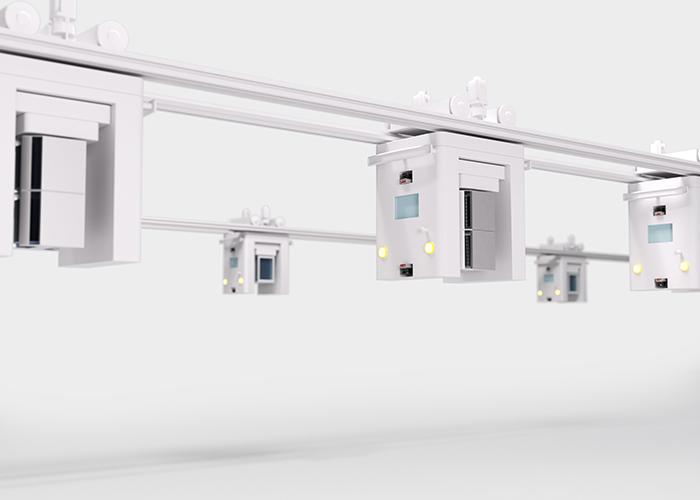

Intelligent window monitoring supports proactive maintenance, thereby maximizing industrial plants’ operating time. Thanks to their space-saving design, the devices can be easily integrated into compact production environments or streamlined automated guided vehicles (AGVs) – for maximum flexibility with minimum installation effort.

Overview

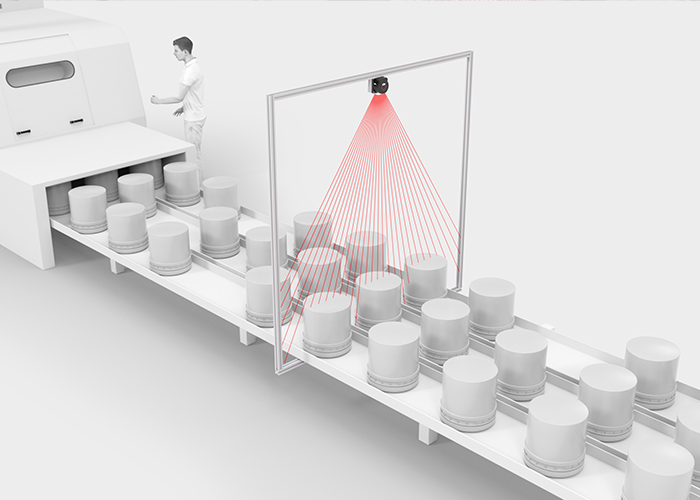

Switching laser scanner for multiple object detection and collision protection tasks

The ROD 100 series’ switching laser scanners are suitable for precise detection of one or more objects as well as for collision protection tasks. They stand out for their high scanning rates with high angular resolution. The switching frequency of 80 Hz allows high traverse and transport speeds. The integrated window monitoring supports predictive maintenance and ensures high system availability. Thanks to their compact design, the laser scanners can also be easily integrated into confined production environments and small automated guided vehicles (AGVs).