Area guarding at transverse transfer car

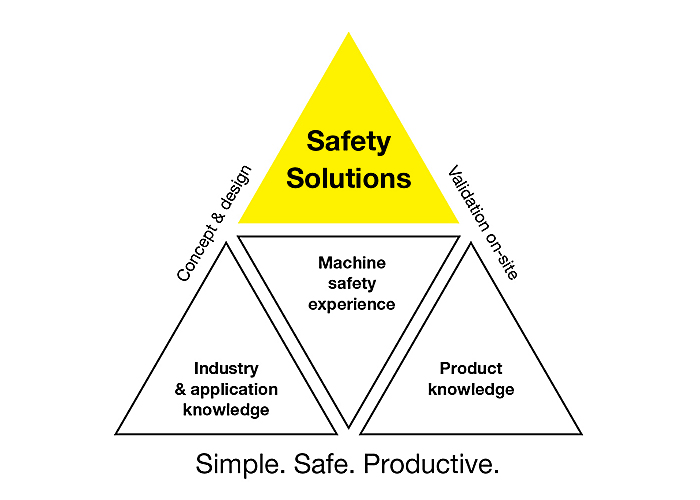

From risk assessment to validation: our safety solutions provide complete solutions for your systems. Our expert teams’ innovative safety concepts ensure efficient material flow, gapless safety and high availability of your system. Even in applications where classic concepts are pushed to their limits. Always with legal certainty, CE certification and compliance with standards. This makes deploying them extremely easy for you.

In high-bay warehouses, transverse transfer cars transport goods between the shelf locations and the entry and exit points. Access to this danger zone must be prevented. This is why the aisles are usually fenced off from the workplaces and the travel path. The revised standard EN 619 (Continuous handling equipment and systems – Safety requirements for equipment for mechanical handling of unit loads) defines which measures are required in order to consider access to the danger zone “prevented”. Besides purely structural measures, contactless protective devices that stop movement when triggered can also be used for this purpose. This offers more flexibility in the design of the system and the goods that can be transported. Our safety solution is based on the requirements of the revised EN 619. It improves the level of safety throughout the entire travel range of the transverse transfer car and also during possible service activities. The system works independently and is easy to integrate. It also keeps all options open for optimizing throughput, as the entire length of the aisle is free to use and the vehicle speed is not limited.

Requirement:

The transportation path of the transverse transfer car must be monitored for the presence of persons using safety laser scanners. To ensure optimum utilization of the hall’s surface area, the car must move right up to the wall. For this purpose, the protective field of the safety laser scanner must gradually be reduced as the car approaches the wall.

Solution:

An area protection system with a safety laser scanner in each direction of travel is installed on the transverse transfer car. The autonomous system detects when the car is approaching the adjacent wall, and automatically reduces the size of the protective field of the safety laser scanner.

Operating principle:

A safety system with a safety laser scanner is installed on the transfer car for each direction of travel. This secures the area in front of the transfer car in the rack aisle. The scanner detects the presence of people and objects and can therefore initiate a safe stop. It also detects the approach to the end of the aisle. The control unit uses this information to adjust the protective field: the protective field is reduced when approaching and increased again when moving away. The entire process is monitored for safety and does not affect the speed of the transfer car.

Advantages for you

- Improving the safety concept in the transfer car’s entire travel range while maintaining high system performance

- Simple integration: The systems work autonomously, they do not require any signals from the transfer car

- The systems can be easily integrated into the safety circuit via the two-channel safety output and can also be easily retrofitted

- Even for the operation of two cars in one aisle

System components and safety parameters

Area protection system using the following in each direction of travel

| Safety sensor: RSL 400 safety laser scanner | |

| System control: MSI 400 safety control | |

| Leuze safety program | |

| PL d in accordance with ISO 13849-1, SILCL 2 in accordance with IEC 62061 | |

| 2-channel safety output |