5B series

Sensors with convincing cost-effectiveness

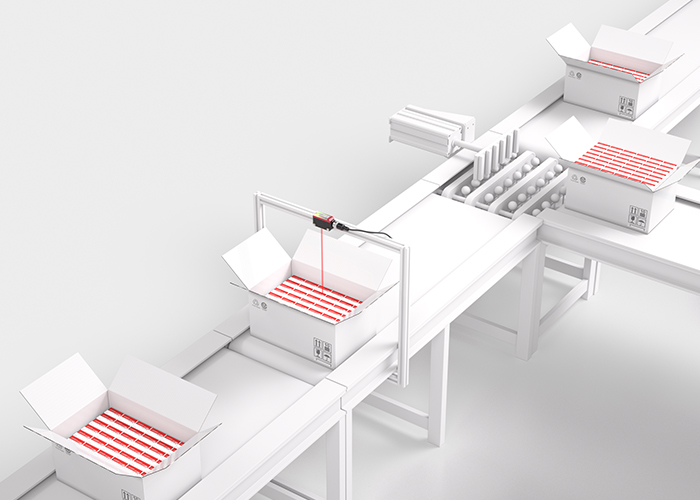

Presence monitoring in intralogistics and packaging processes as well as in the automotive industry with the 5B series

When carrying out presence checks in automated processes, the sensor system should reliably detect different objects. The handling of the sensor, including mounting, alignment and adjustment, should also be quick and easy, especially since a large number of sensors often have to be installed. Therefore, standardization on the one hand and adaptation of the sensor to the individual needs of the customer on the other are very important for cost-efficient commissioning of a system. For even greater flexibility in use, variants with light/dark switching via potentiometer or reverse polarity protection have been added.

We have developed an optimized sensor generation precisely for these requirements:

The 5B series. Convincingly economical. Perfect handling.

Advantages for you

- Flexible in use: Full range of products with all operating principles, each in identical and mounting-compatible housings. You can choose between throughbeam photoelectric sensors, retro-reflective photoelectric sensors and diffuse sensors to suit the respective application

- Variants for light/dark switching available on the sensor

- Housing: New, more compact housing (dimensions W x H x L: 11mm x 32.4mm x 20mm) – mounting compatible with predecessor series – ideal for confined installation situations. With protection class IP 67 and ECOLAB certified

- Fastening and installation: Quick fastening and easy installation thanks to metal inserts with M3 thread

- Commissioning: 360° visible display LEDs for easy installation and status display. Fast alignment through homogeneous and highly visible light spot

- Optimal configuration: Simple adjustment and adaptation to the application through user-friendly potentiometer

- Reliable detection of depolarizing objects: Optimized performance for the detection of reflective, shrink-wrapped, and shiny objects

- Electrical connection: Adaptation to individual customer requirements through various connection options (e.g., cable, M8 connector, pigtail, etc.)

- Switching frequency: Improved switching frequency of up to 900 Hz for throughbeam photoelectric sensors and up to 1,000 Hz for diffuse sensors for high performance and function reserve

- Tamper-proof: Light/dark switching is tamper-proof via the polarity reversal of the (cable) wiring

Available operating principles:

Retro-reflective photoelectric sensor

Throughbeam photoelectric sensor

Diffuse sensors

Highlights

Cost-effective installation

The greater the number of sensors to be installed on a conveyor line, the more important their cost effectiveness becomes in terms of time and costs for mounting and commissioning.

The intelligent and simple fastening concept with two convenient M3 metal threads facilitates fast mounting for the user.

The small and compact housing design also makes installation in small spaces easier.

Depending on your individual preference or local installation situation, various connection types are available, e.g., with M8 connector, cable, or pigtail connector.

Quick and easy commissioning and adjustment

360° visible display LEDs ensure easy installation and a clearly visible status display. The simple alignment of the sensor using the highly visible light spot also saves time and thus reduces costs for the user. The new 5B series is also available with a potentiometer for better fine adjustment of the sensor. This allows the sensor to be quickly and easily adapted to changing conditions in the application.

In addition, the light/dark switching of the switching output can be implemented in a tamper-proof manner via the wiring.

Reliable detection even with depolarizing objects

In conveyor and storage systems, pallets, cardboard boxes, and other containers are often wrapped in film, which can present challenges for sensor technology. With the new 5B series, we offer optimized variants specifically for this area of application. These sensors guarantee reliable switching even with shrink-wrapped or shiny objects.

Greater flexibility

When replacing sensors, the original switching behavior is not always obvious. To simplify selection, this series lets you switch between light and dark operation simply by reversing the supply voltage polarity. Additionally, variants with “.1X” in the item number allow the switching behavior to be adjusted via a potentiometer, even after installation. The mark on the potentiometer shows the setting.

Application

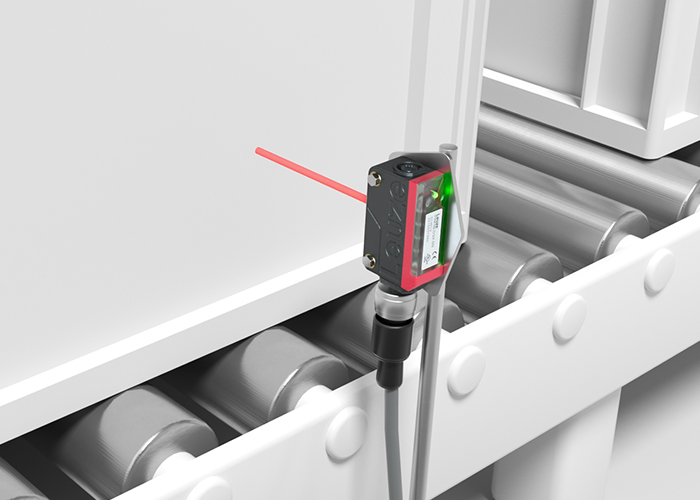

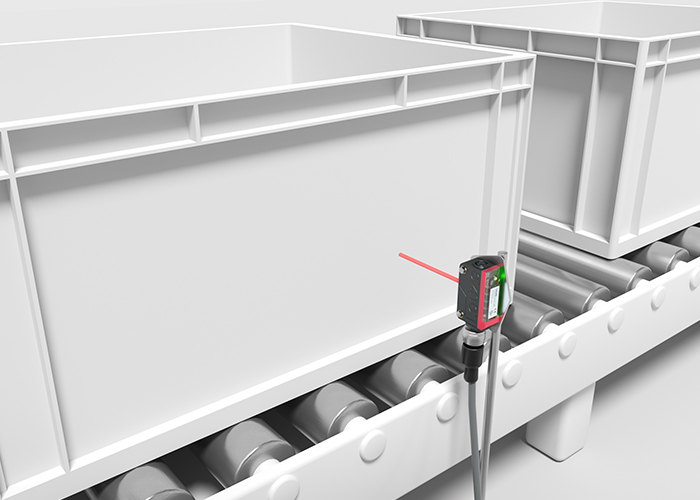

Presence checking in the area of intralogistics with retro-reflective photoelectric sensor

Requirement:

In a logistics center, various containers and boxes are to be transported on roller conveyors that are close together. Some boxes are also shrink-wrapped with film. All objects must be reliably detected. When the sensor is commissioned, it must be possible to install, align and adjust it quickly and easily. The light spot must be clearly visible.

Solution:

The new sensor of the 5B series can be mounted directly on the roller conveyors, which are close together, thanks to its compact housing. Convenient metal inserts with an M3 thread are used for installation and high-strength mounting. Alignment is quick and easy thanks to a homogeneous and highly visible light spot and 360° visible display LEDs. The adjustment is user-friendly via potentiometer. Thanks to the optimized performance for the detection of shrink-wrapped and shiny objects, these can also be reliably detected.

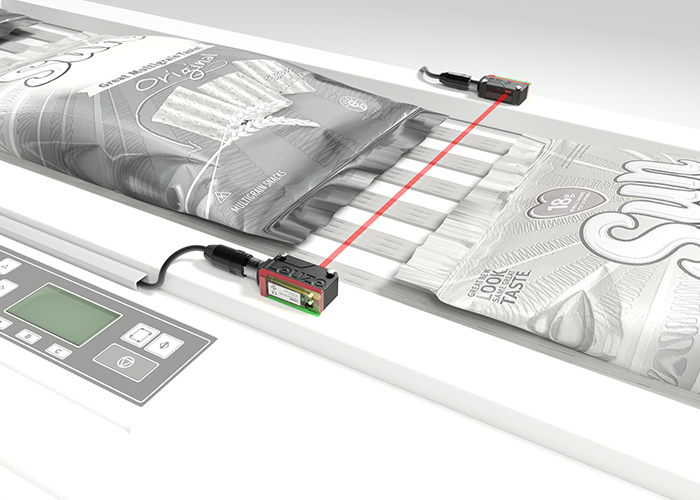

Presence control in the area of packaging technology with a throughbeam photoelectric sensor

Requirement:

A food manufacturer packs chips in primary packaging. The packages are then transported further on a conveyor line and are to be reliably detected there. The light spot should be visible. The sensor status should also be visible from a distance of 2 m.

Solution:

The new 5B series sensor can also be mounted horizontally on the conveyor line and the light spot is clearly visible. The sensor status can be seen at all times, even from a distance from the conveyor line, thanks to the bright, 360° display LEDs. The advantage of choosing a throughbeam photoelectric sensor is that it has a very high performance reserve, which enables reliable detection even under demanding environmental conditions and reduces the risk of system downtime. The new 5B series also features an optimized switching frequency of 900 Hz.

Presence checking in intralogistics with a diffuse sensor

Requirement:

Packages are transported in a distribution system on a conveyor belt. A sensor is to check whether the packages are properly filled. Boxes that are underfilled or overfilled are to be ejected.

Solution:

The HT 5B diffuse sensor looks down on the conveyor belt and detects the boxes and their contents with a fast switching behavior of up to 1,000 Hz. Adjustment and fine-tuning are user-friendly and are performed via potentiometers. The background suppression of the sensors ensures that only the object is detected and the conveyor belt is suppressed.

Detection of a film tear in battery cell production with diffuse sensors

Requirement:

During the production of lithium-ion battery cells, rolled copper or aluminum foils are compressed in a complex process (calendering). High and irregular speeds can cause the film web to tear. Sensors are used to stop the process immediately to prevent damage to the machine.

Solution:

The HT 5B diffuse sensor with background suppression continuously monitors the presence of the film and immediately detects a film tear. The sensor also reliably detects very shiny or dark surfaces and, thanks to its compact design, is also suitable for very cramped installation situations.

Technical features

| Parameter | Retro-reflective photoelectric sensors | Throughbeam photoelectric sensors | Diffuse sensors |

| Switching frequency | 500 Hz | 900 Hz | 1,000 Hz |

| Operating range | 6.5 m | 15 m | 400 mm |

| Light source | Highly visible red light, Power PinPoint | Highly visible red light, infrared | Highly visible red light, infrared |

| Operational control | Potentiometer | - | Potentiometer |

| Housing dimensions (W x H x L) | 11 x 32.4 x 20 mm | 11 x 32.4 x 20 mm | 11 x 32.4 x 20 mm |

| Housing material | Plastic | Plastic | Plastic |

| Protection class | IP 67 | IP 67 | IP 67 |

| Compatibility of materials | ECOLAB | ECOLAB | ECOLAB |

| Connection | M8 / cable / pigtail | M8 / cable / pigtail | M8 / cable / pigtail |