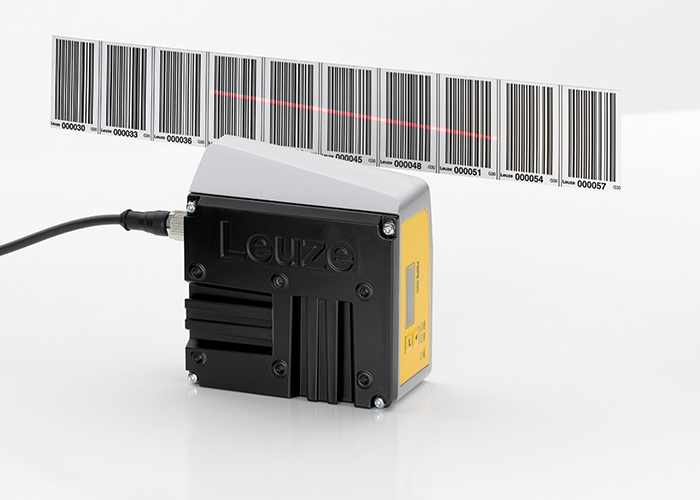

Posicionamiento preciso mediante código de barras

El sistema de posicionamiento seguro por código de barras FBPS 600i de Leuze ahora también está disponible con interfaz PROFIsafe. Esto hace que las características de seguridad sean especialmente fáciles de implementar.

Owen, September 1, 2025 – Leuze ofrece ahora el sistema de posicionamiento seguro por código de barras FBPS 600i en un modelo adicional con interfaz PROFIsafe. La interfaz permite a los usuarios conectar el dispositivo directamente a un PLC seguro, lo que facilita un diseño especialmente compacto y simplifica la instalación. Como alternativa, el sistema de posicionamiento seguro de código de barras sigue estando disponible con dos interfaces SSI. Ambos modelos son adecuados para aplicaciones hasta el nivel de rendimiento e, por ejemplo, para el posicionamiento exacto de grúas, incluidas los transelevadores. Una ventaja clave de todos los modelos de dispositivos es que detectan posiciones de forma fiable utilizando un solo sensor. De este modo, los operadores del sistema se benefician de unos costes de integración y mantenimiento considerablemente más bajos.

Integración directa con PLC

La interfaz PROFIsafe permite a los usuarios integrar el sistema de posicionamiento seguro por código de barras FBPS 600i directamente en un control de seguridad. Este modelo de dispositivo también tiene una interfaz SSI no segura, lo que permite una conexión al convertidor de frecuencia que controla el transelevador o una máquina similar. El modelo PROFIsafe también ofrece una función de salida de velocidad segura. La parametrización se puede realizar cómodamente a través del gestor de hardware utilizando un archivo GSDML o directamente a través de los ajustes de configuración del convertidor de frecuencia. Y hay otra ventaja más: gracias al interruptor integrado se pueden conectar varios dispositivos en serie utilizando una topología lineal, si es necesario.

Haz de exploración inclinado para una fiabilidad máxima

El sistema de posicionamiento seguro por códigos de barras FBPS 600i es excepcionalmente fiable. Se instala en el transelevador, el carro de transferencia transversal o la grúa. En el reverso lleva pegada una cinta con código de barras resistente a los rayos UV. El FBPS 600i captura múltiples códigos con cada proceso de escaneo. A continuación, el software utiliza los códigos para determinar valores de posición de gran precisión. Leuze ha diseñado el sistema de posicionamiento de tal manera que el haz de escaneo está inclinado, lo que hace que escanee cada código en diferentes puntos a medida que se mueve. De esta forma se evitan errores de lectura causados por suciedad o daños locales. Otra ventaja más es el breve tiempo de respuesta ante errores, de solo 10 milisegundos, lo que permite su uso incluso en transelevadores muy rápidos.

Un tornillo es suficiente

La instalación resulta muy sencilla gracias al amplio rango de trabajo de entre 50 y 170 milímetros y al ingenioso sistema de fijación. El dispositivo se fija de forma segura al soporte de la abrazadera con un solo tornillo de fácil acceso. Esto quiere decir que el FBPS 600i se puede sustituir rápidamente cuando es necesario realizar tareas de mantenimiento.