Precise processes for the e-drive

With sensor expertise for high-voltage batteries

It all starts with the cell

High-gloss surfaces

A compact approach to safety

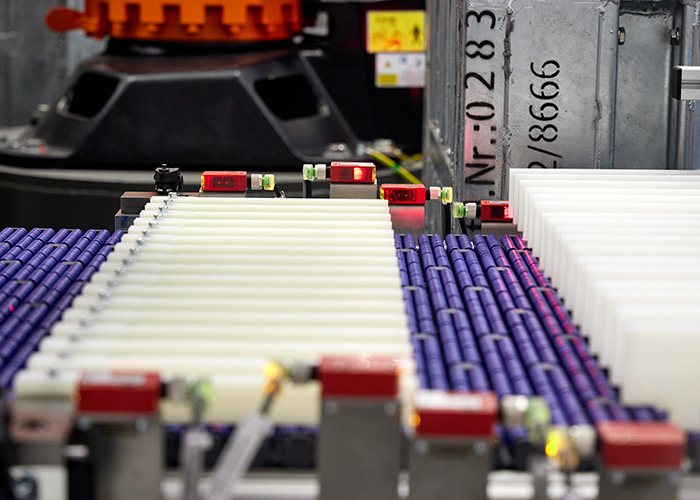

Perfectly positioned

From stacking to the module

Everything in sync

The author

.jpg) |

Martina Schili Leuze electronic GmbH + Co. KG Telephone: +49 7021 573-116 Web: www.leuze.com |