33C/ 35C series

Robust and hygienic: On the safe side with stainless steel sensors

Largest selection of photoelectric sensors in stainless steel housings

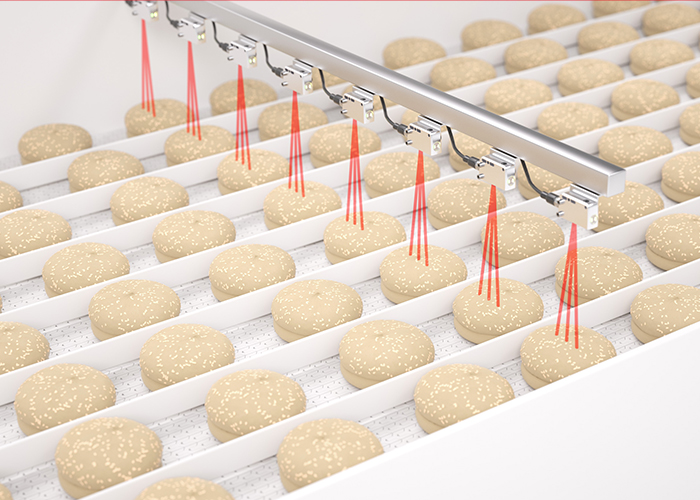

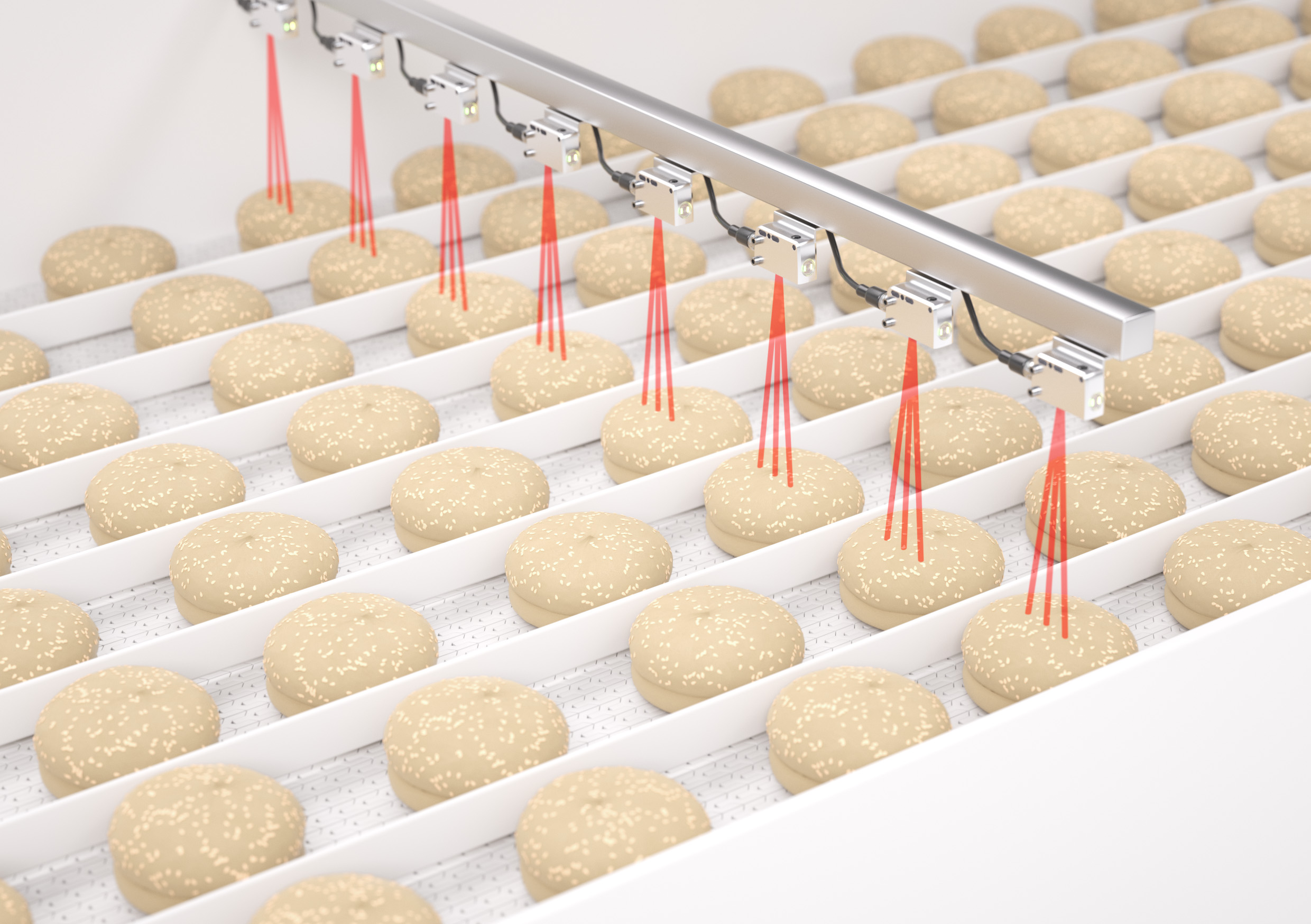

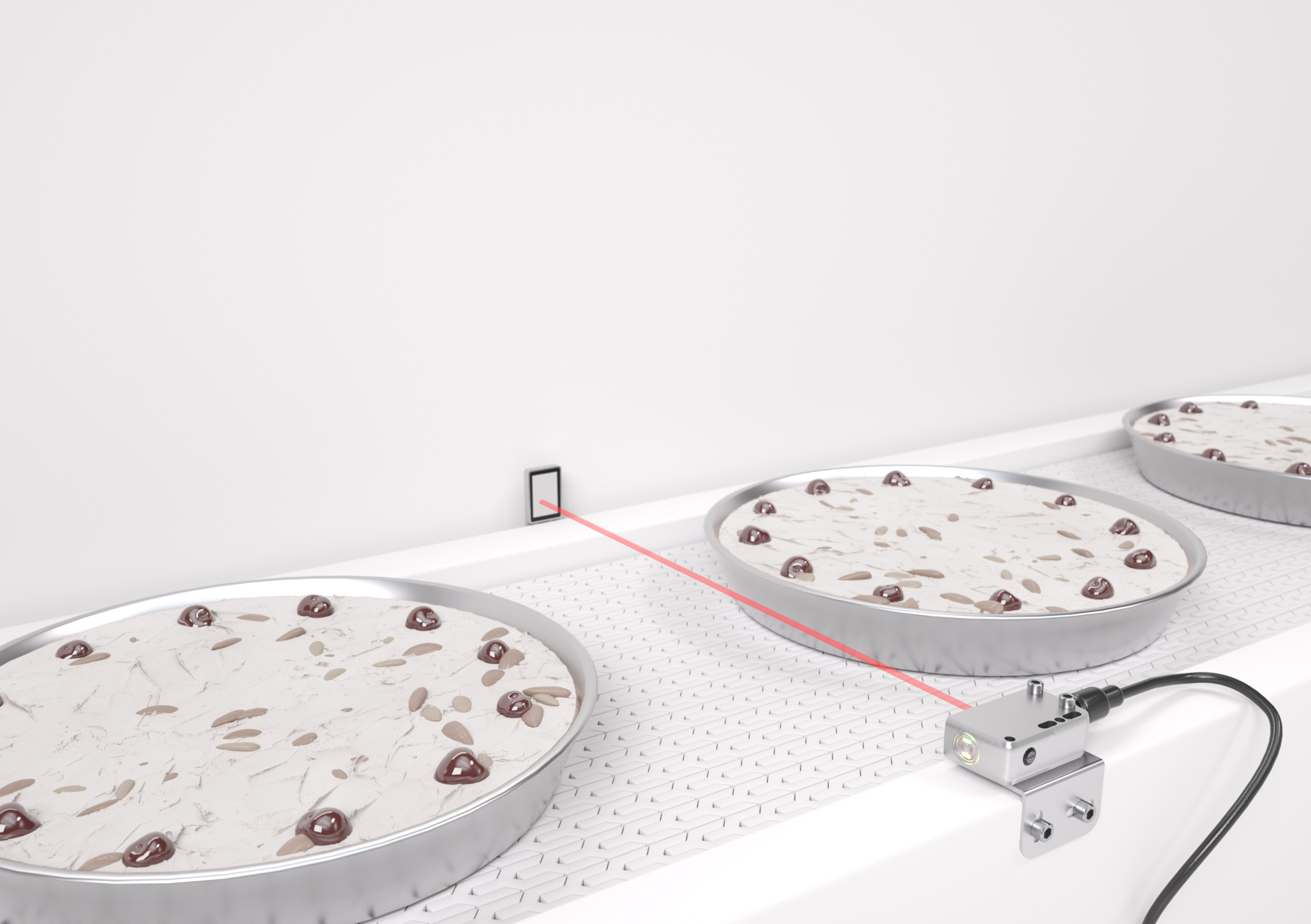

33C series: Specialist for hygienic processes in the food industry

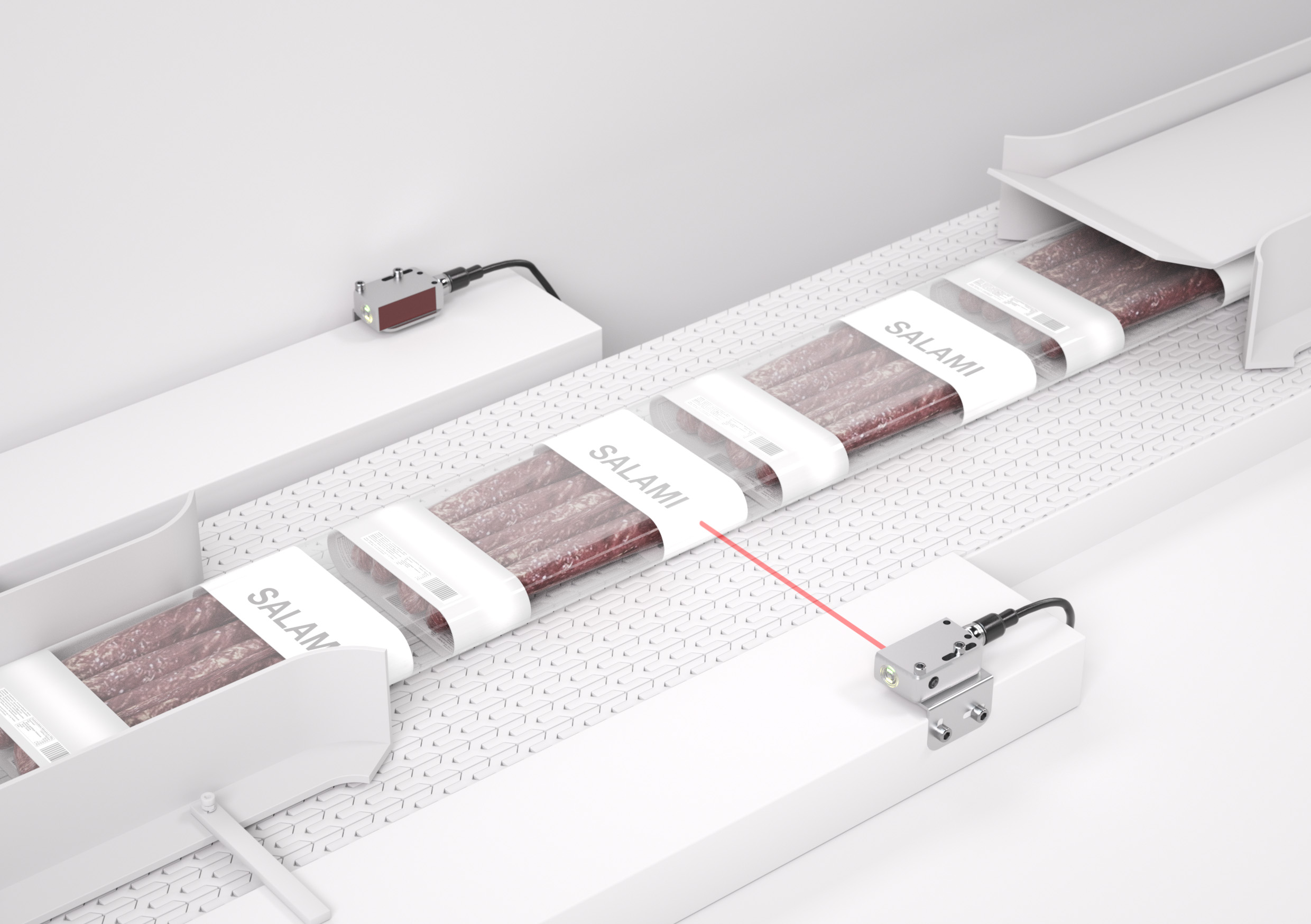

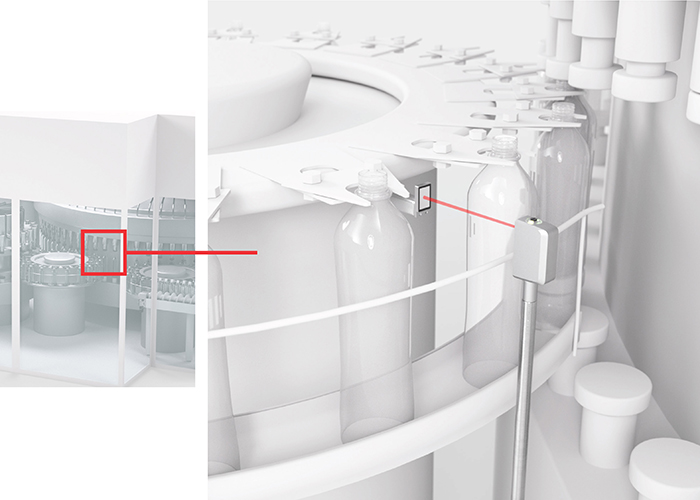

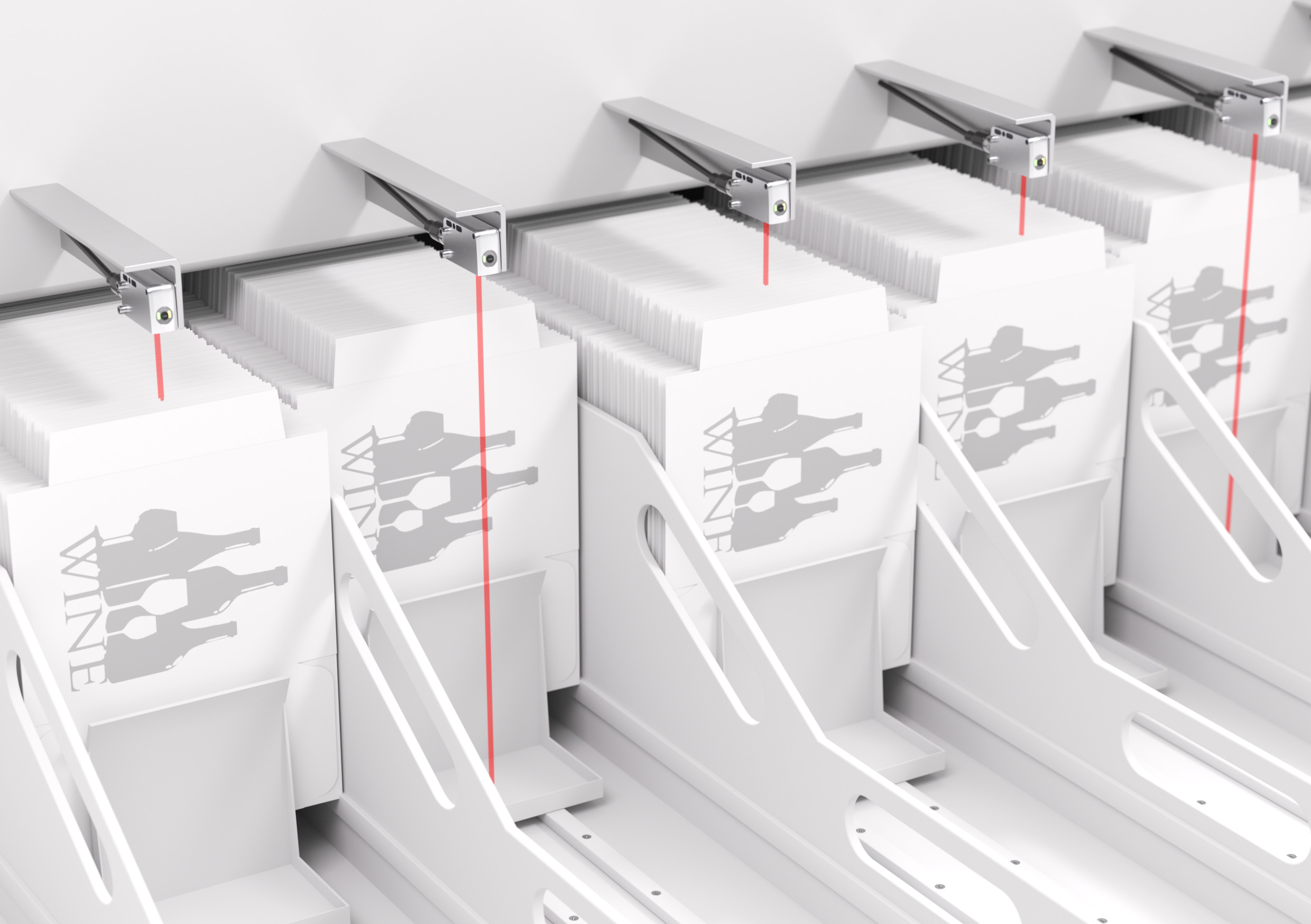

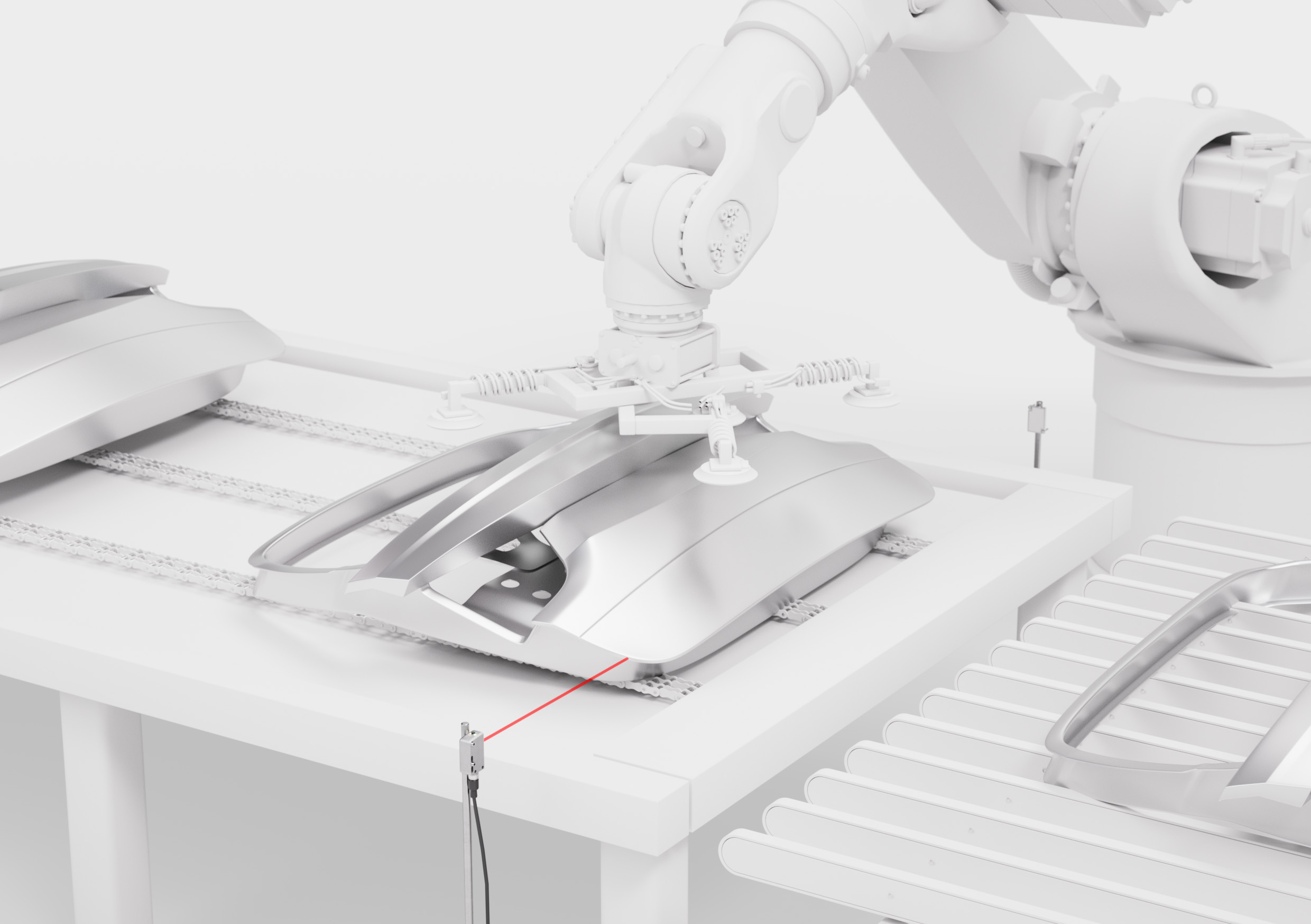

35C series: Robust all-rounder for packaging processes, the automotive industry and for machine tools

Harsh environments require perfectly matched solutions

Your requirements for machines and systems, as well as the appropriate sensor technology, are high: Our sensors offer you perfectly matched solutions.

Impermeability

Systems and the sensors installed in them are very often cleaned with high-pressure cleaners. Sensors are constantly exposed to moisture and humidity due to the high number of cleaning cycles.

- Absolutely sealed housing

- Diffusion-tight materials for optical covers and operating elements

- protection classes IP 67, IP 68 and IP 69K

Chemical requirements

Regular cleaning cycles with foam cleaners, disinfectants, alkaline or basic cleaners require resistant sensors.

- ECOLAB certification

- Diversey certification

- Clean Proof+-certification

Thermal requirements

Strong temperature fluctuations between ambient temperature and cleaning temperature put a high load on sensors.

- Sensor tests in the climate cabinet

- Thermal shock tests (water bath hot-cold)

- Steam jet test as part of the IP 69K approval

- Temperature ranges from -40 °C to +70 °C

Mechanical resistance

In harsh production environments, sensors are exposed to dust, shavings, vibrations and other mechanical stresses.

- Absolutely sealed housing

- Robust housing: no additional housing necessary

- Vibration and shock resistance

To the point: Power PinPoint® LED

Everything from a single source: connection cables, mounting parts and reflectors

In demanding environments, not only the sensors but also the connection cables, mounting parts and reflectors must meet the high requirements. Our connection cables are approved for direct contact with food (FDA-compliant materials). The cables achieve the IP 69K degree of protection and thus withstand intensive cleaning processes with high-pressure cleaners (important: must be installed with a special tightening torque). ECOLAB certification confirms the cables' resistance to aggressive cleaning agents. The cable portfolio for use in hygienically demanding industrial areas includes M8 and M12 as well as cable lengths of 2, 5 and 10 meters.

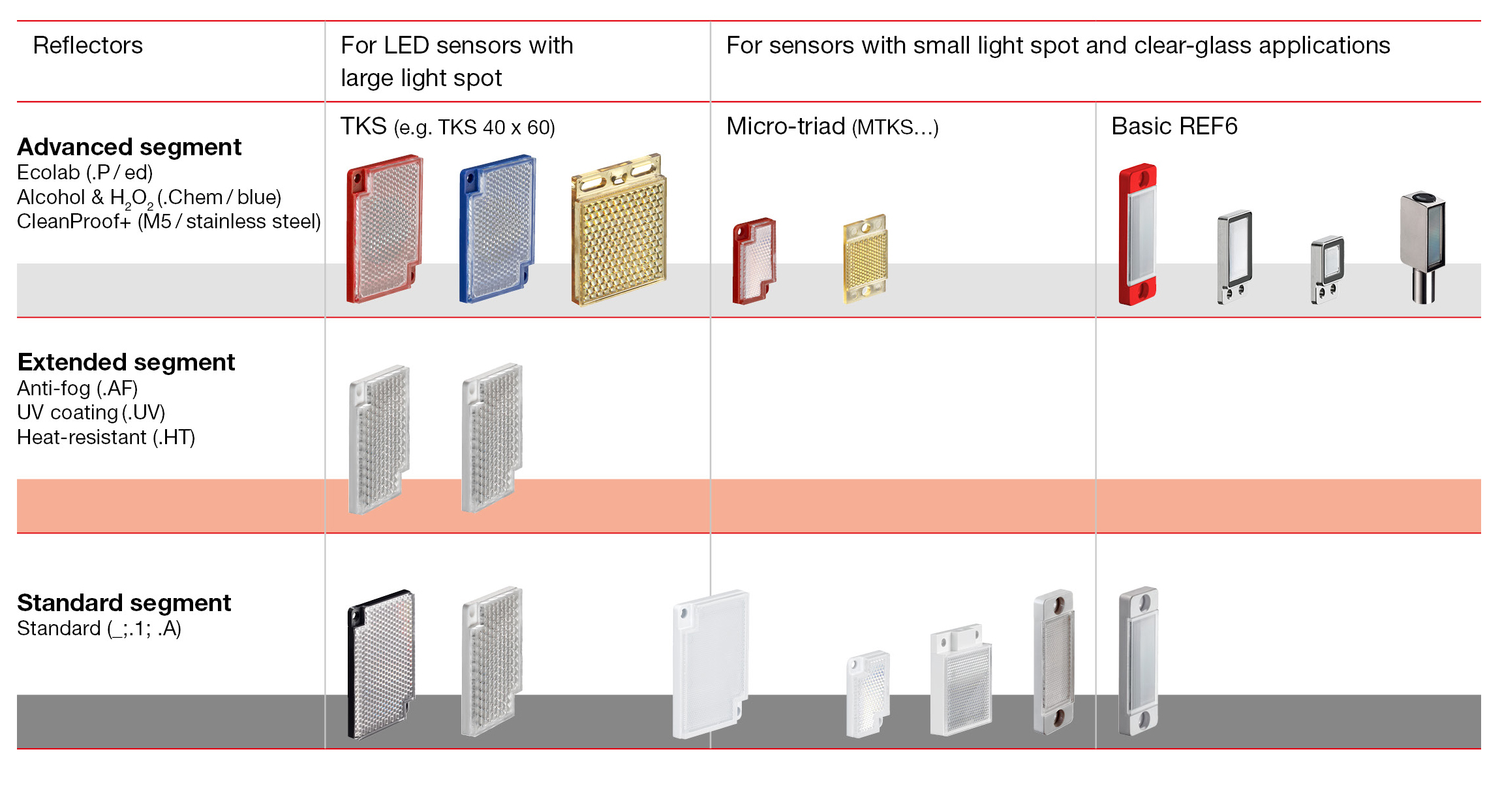

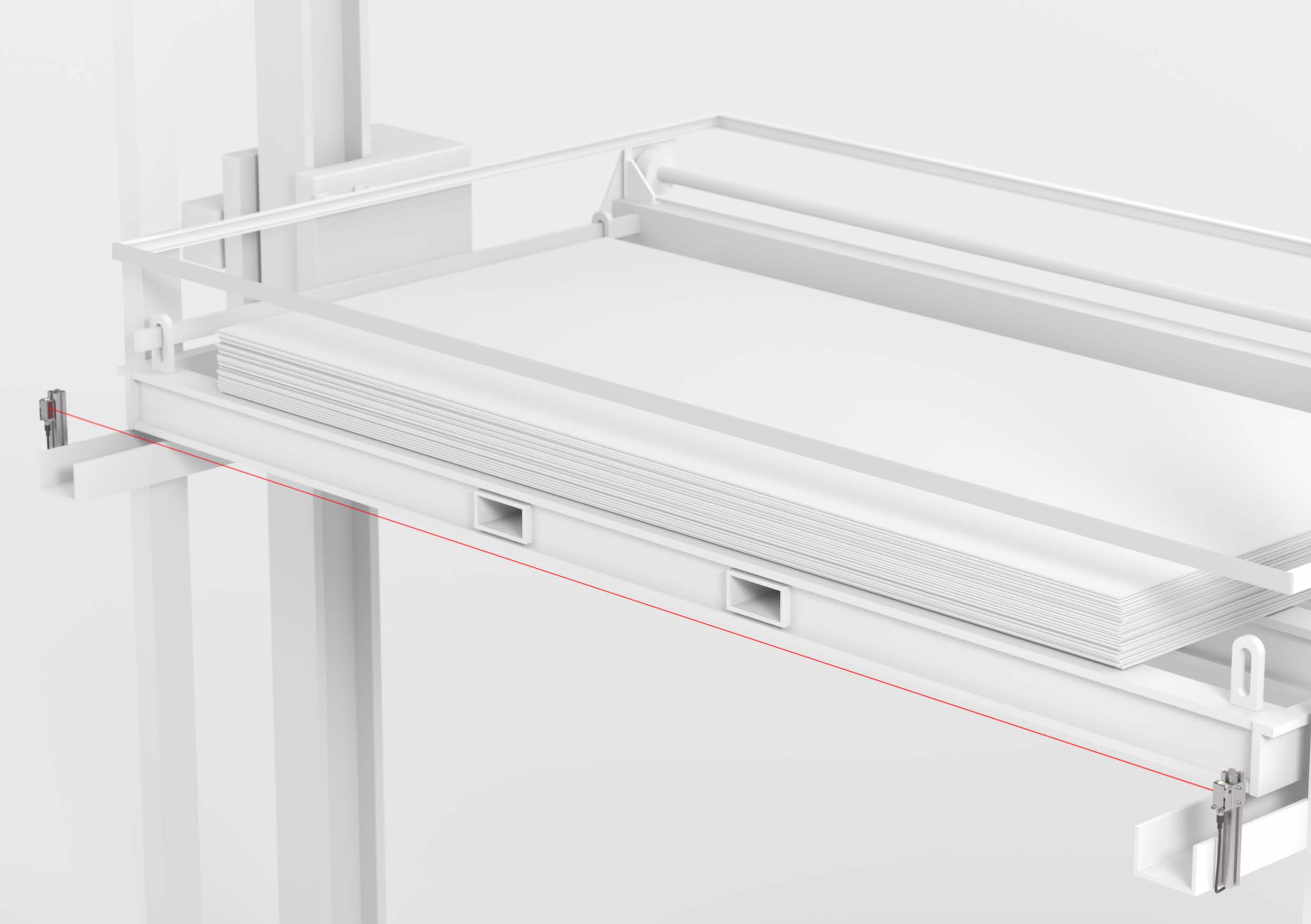

Reflectors

Just how reliably retro-reflective photoelectric sensors can detect depends upon the selected reflector, among other things. We offer reflectors with plastic or stainless steel housings as well as reflective tapes for different requirements: Reflectors in the advanced segment are often used in the food and pharmaceutical industry on account of their resistance against cleaning agents. The Solidchem reflectors made of chemically resistant plastic also stand out for their high temperature resistance. The reflectors from the extended segment are suitable for production areas with high air humidity or large differences in temperature.