Minimale afmetingen, maximale veiligheid

De kleinste veiligheidslaserscanner op de markt: De RSL 200 van Leuze

In de industriële automatisering moeten efficiëntie en veiligheid hand in hand gaan: Mensen, machines en processen moeten betrouwbaar worden beschermd zonder de productieprocessen te belemmeren. De ruimte is echter beperkt in smalle productielijnen, op automatisch geleide voertuigen en robots. Hier scoort de nieuwe ultracompacte RSL 200 veiligheidslaserscanner van Leuze punten: als kleinste veiligheidslaserscanner op de markt kan hij moeiteloos worden geïntegreerd en flexibel worden ingezet om gevarenzones en toegangspunten te beveiligen.

Veiligheidslaserscanners staan in bijna elke branche steeds meer in de schijnwerpers. Dat komt omdat de veelzijdige apparaten in veel gevallen onmisbaar zijn om de hoogste veiligheidsnormen voor de bescherming van personen te waarborgen. Dankzij configureerbare beschermings- en waarschuwingsvelden kunnen ze zeer flexibel worden ingezet voor de beveiliging van gevarenzones en toegangen – zowel voor stationaire als mobiele toepassingen. Een typisch toepassingsgebied is het beveiligen van de gevaarlijke werkzones van een machine tegen toegang en aanwezigheid van personen. Laserveiligheidsscanners zijn ook ideaal voor het beveiligen van autonome mobiele robots (AMR's) en bestuurderloze transportsystemen, ook wel bekend als automatisch geleide voertuigen (AGV's).

Maximale veiligheid in de kleinste ruimte: De toekomst van laserscanners

Moderne veiligheidslaserscanners moeten aan een breed scala aan eisen tegelijk voldoen: Naast hun hoofdtaken, namelijk het veilig uitschakelen van machines of systemen, mogen ze de beschikbaarheid van machines niet beperken of tot onnodige stilstand leiden. Bovendien wordt van laserscanners een indrukwekkend bereik en een indrukwekkende scanhoek verwacht, terwijl de systeemoperator uitgaat van veiligheidsclassificaties volgens type 3, SIL 2 en PLd. De systeemoperator moet ook kunnen vertrouwen op een gemakkelijke configuratie en diagnostiek, die moeiteloos en intuïtief kan worden uitgevoerd via verschillende interfaces zoals Bluetooth, USB of Ethernet TCP/IP. Tot slot worden moderne veiligheidslaserscanners geselecteerd op basis van hun apparaatgrootte. Dat komt omdat door de toenemende automatisering ruimtelijke efficiëntie in veel productieomgevingen steeds belangrijker wordt. Systemen worden complexer, terwijl de beschikbare ruimte voor veiligheidstechnologie kleiner wordt. Er is vaak weinig ruimte voor, vooral bij mobiel gebruik op AGV's.

Er zijn innovatieve oplossingen nodig om deze uitdagingen het hoofd te bieden. The Sensor People van Leuze zetten nieuwe normen op het gebied van vormfactor met hun geavanceerde veiligheidslasertechnologie, waarbij de gebruiker voorop staat. De ultracompacte RSL 200 veiligheidslaserscanner is momenteel het kleinste apparaat op de markt. Het combineert de modernste LiDar-technologie in een minimale ruimte van slechts 80 x 80 x 86 millimeter. Hierdoor is het eenvoudig te integreren, zelfs in extreem krappe ruimtes, zowel in stationaire als mobiele toepassingen. Als er grotere werkbereiken nodig zijn, kan de grotere RSL 400 met een werkbereik tot 8,25 meter worden gebruikt.

Eenvoudige installatie vandaag

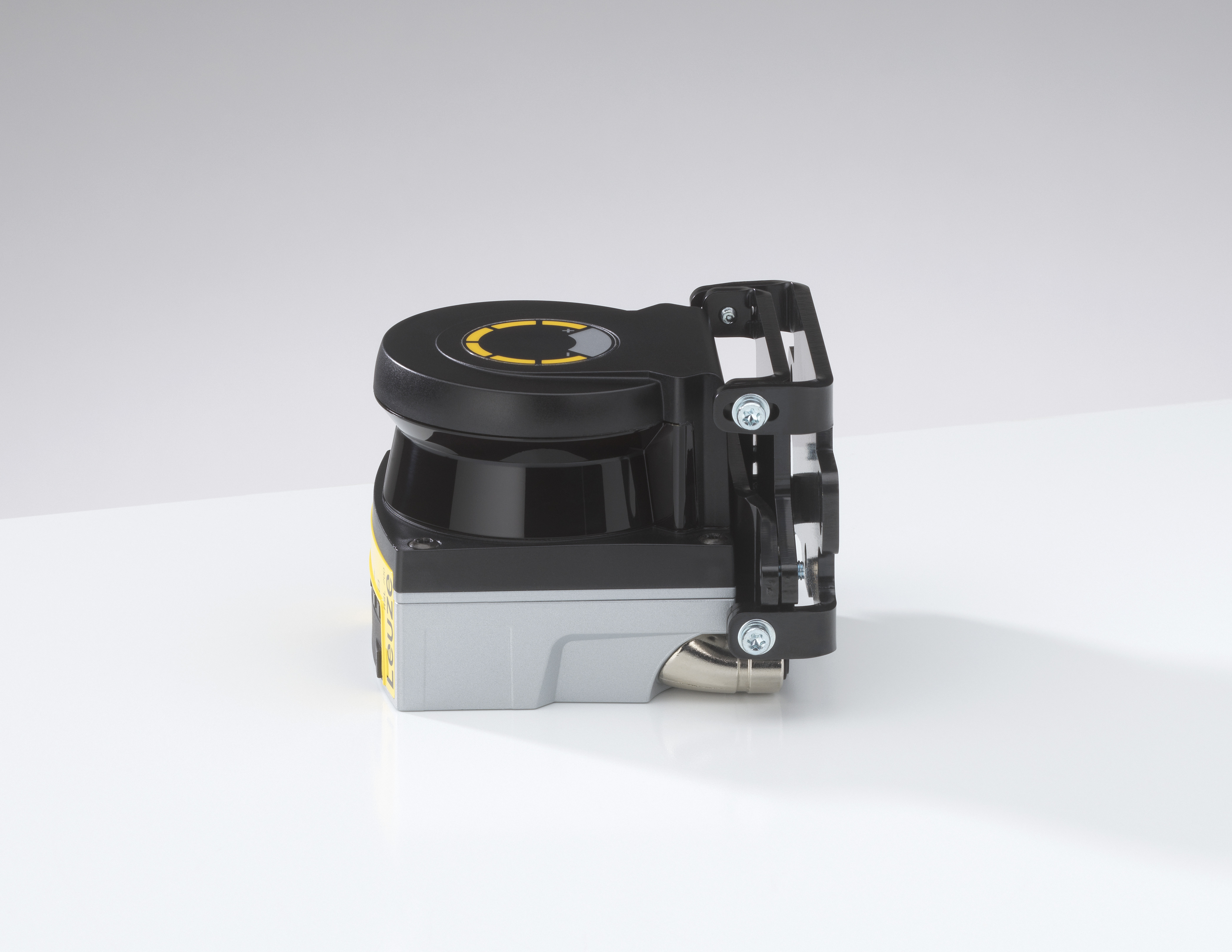

De compacte veiligheidsscanner van Leuze biedt de gebruiker meer mogelijkheden voor een eenvoudige en flexibelere installatie, met name in krappe omgevingen, dankzij de ruimtebesparende montagebeugel of aansluittechnologie. De juiste montageaccessoires zijn essentieel voor een snelle integratie: Daarom heeft Leuze een eigen innovatieve montagebeugel voor de RSL 200 ontwikkeld, die een moeiteloze bevestiging mogelijk maakt en waarmee het scanniveau van de veiligheidslaserscanner horizontaal en verticaal kan worden uitgelijnd.

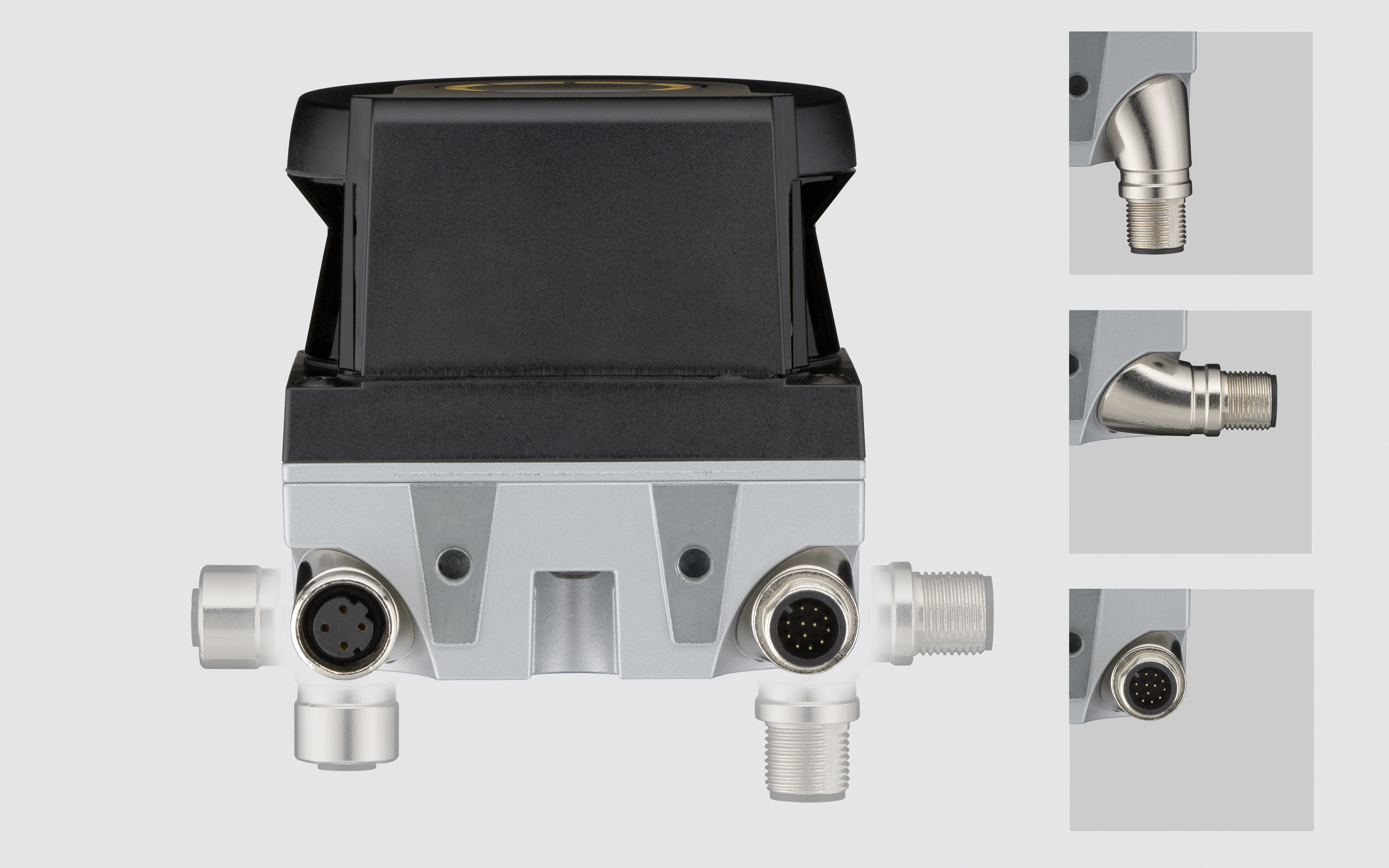

Ook eenvoudig onderhoud is gegarandeerd: De RSL 200 kan snel en eenvoudig worden vervangen met slechts vier schroeven, en de sensorparameters kunnen via een geheugenkaart van de oude naar de nieuwe sensor worden overgebracht zonder dat er sensorkennis nodig is. Aansluitingen en kabels mogen evenmin obstakels vormen. Draaibare M12-aansluitingen op de RSL 200-laserscanner maken een uiterst flexibele kabelgeleiding mogelijk voor I/O's, stroomvoorziening en gegevensoverdracht. Dit zijn essentiële criteria, met name voor gebruik op kleine AGV's.

The Sensor People biedt ook een nieuwe mobiele diagnose-app waarmee statusinformatie gemakkelijk kan worden opgevraagd, zelfs als de laserscanner op moeilijk of onmogelijk toegankelijke locaties is geïnstalleerd.

De innovatieve montagebeugel die speciaal voor de RSL 200 is ontwikkeld, maakt het zeer eenvoudig om de veiligheidslaserscanner horizontaal en verticaal uit te lijnen. Indien onderhoud nodig is, kan de laserscanner snel en eenvoudig worden vervangen met slechts vier schroeven.

Afgestemd op al uw eisen

Om een veiligheidslaserscanner optimaal te laten functioneren, zijn ook de ‘innerlijke’ waarden van belang. Zo moet de scanhoek groot genoeg zijn om de toepassingsspecifieke veiligheidstaak betrouwbaar te vervullen, bijvoorbeeld om dode hoeken of moeilijk zichtbare zones achter machines of transportbanden volledig te bestrijken. Hij moet ook kleine omnidirectionele AGV's/AMR's in alle richtingen kunnen beveiligen – de RSL 200 van Leuze biedt bijvoorbeeld een scanhoek van 275 graden bij een bereik van drie meter. Dankzij de grote scanhoek kan de gebruiker met slechts twee diagonaal geplaatste apparaten een rondom bescherming garanderen, zelfs rekening houdend met montagetoleranties.

Met 32 schakelbare sets beschermings- en waarschuwingsvelden kan de AGV/AMR-gebruiker de snelheid en rijrichting continu aanpassen. De bewaakte gebieden kunnen zo optimaal worden aangepast aan gebogen paden, verschillende snelheden en diverse beladingstoestanden.

Samenvatting

De volgende generatie veiligheidslaserscanners begint met de RSL200. Dankzij zijn ultracompacte afmetingen kan hij gemakkelijk worden geïntegreerd, zelfs in extreem krappe ruimtes, zowel stationair als mobiel. Voordelen zoals de innovatieve, ruimtebesparende montagebeugel en draaibare M12-aansluitingen dragen hier ook aan bij. Bovendien kunnen systeembeheerders met de mobiele diagnose-app van Leuze alle statusinformatie op elk moment gemakkelijk via Bluetooth opvragen, zelfs als de laserscanner op een ontoegankelijke of moeilijk bereikbare plaats is geïnstalleerd.

Directeur Business Area Safety bij Leuze